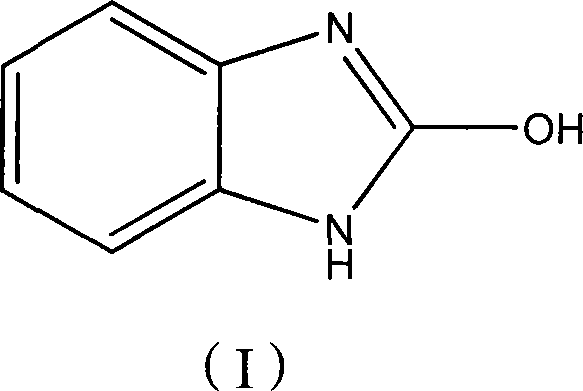

Chemical synthesis method for 2-hydroxybenzimadazoles

A technology for hydroxybenzimidazole and chemical synthesis, applied in the direction of organic chemistry and the like, can solve the problems of large environmental pollution, long steps, low yield and the like, and achieve the effects of less three wastes, low production cost and reasonable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

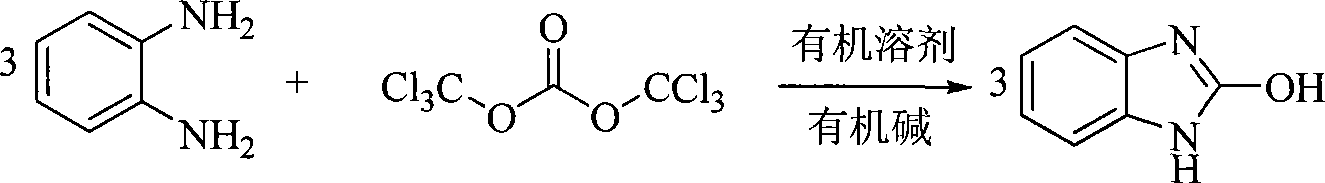

Method used

Image

Examples

Embodiment 1

[0025] The amount of feeding material is o-phenylenediamine, two (trichloromethyl) carbonate, pyridine=1: 0.4: 2.0, the feeding amount of o-phenylenediamine is 250mmol, the feeding amount of two (trichloromethyl) carbonate is 100mmol, the feeding amount of pyridine is 500mmol, and the organic solvent is methylene chloride 540ml, and its volume consumption is 20 times of the quality of o-phenylenediamine.

[0026] In a 500ml three-neck flask equipped with mechanical stirring, a constant pressure dropping funnel and a thermometer, 27g of o-phenylenediamine, 400ml of dichloromethane and 40ml of pyridine were sequentially added, and the temperature of the mixture was controlled at 10°C. Slowly add 140ml of dichloromethane solution that is dissolved with 29.7g of bis(trichloromethyl)carbonate in the mixed solution dropwise, continue to maintain the temperature and stir for 4h after the dropwise addition, filter, wash the filter cake with 100ml of dichloromethane, and then use 120ml ...

Embodiment 2

[0028] The amount of feeding material is o-phenylenediamine, two (trichloromethyl) carbonate, pyridine=1: 0.4: 3.0, the feeding amount of o-phenylenediamine is 250mmol, the feeding amount of two (trichloromethyl) carbonate is 100mmol, the feeding amount of pyridine is 750mmol, and the organic solvent is methylene chloride 540ml, and its volume consumption is 20 times of the quality of o-phenylenediamine.

[0029] In a 500ml three-neck flask equipped with mechanical stirring, a constant pressure dropping funnel and a thermometer, 27g of o-phenylenediamine, 400ml of dichloromethane and 60ml of pyridine were sequentially added, and the temperature of the mixture was controlled at -5°C. Slowly add 140ml of dichloromethane solution that is dissolved with 29.7g of bis(trichloromethyl)carbonate in the mixed solution dropwise, continue to maintain the temperature and stir for 4h after the dropwise addition, filter, wash the filter cake with 100ml of dichloromethane, and then use 120ml ...

Embodiment 3

[0031] The amount of feeding material is o-phenylenediamine, two (trichloromethyl) carbonate, pyridine=1: 0.4: 2.0, the feeding amount of o-phenylenediamine is 250mmol, the feeding amount of two (trichloromethyl) carbonate is 100mmol, the feeding amount of pyridine is 500mmol, and the organic solvent is methylene chloride 432ml, and its volume consumption is 16 times of the quality of o-phenylenediamine.

[0032] In a 500ml three-necked flask equipped with mechanical stirring, a constant pressure dropping funnel and a thermometer, 27g of o-phenylenediamine, 290ml of dichloromethane and 40ml of pyridine were sequentially added, and the temperature of the mixture was controlled at 30°C. Slowly add 142ml of dichloromethane solution that is dissolved with 29.7g of bis(trichloromethyl)carbonate in the mixed solution dropwise, continue to maintain the temperature and stir for 4h after the dropwise addition, filter, wash the filter cake with 100ml of dichloromethane, and then use 120m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com