Semiconductor device and fabrication method thereof

A semiconductor and insulating layer technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as bubbles, metals or oxides, and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

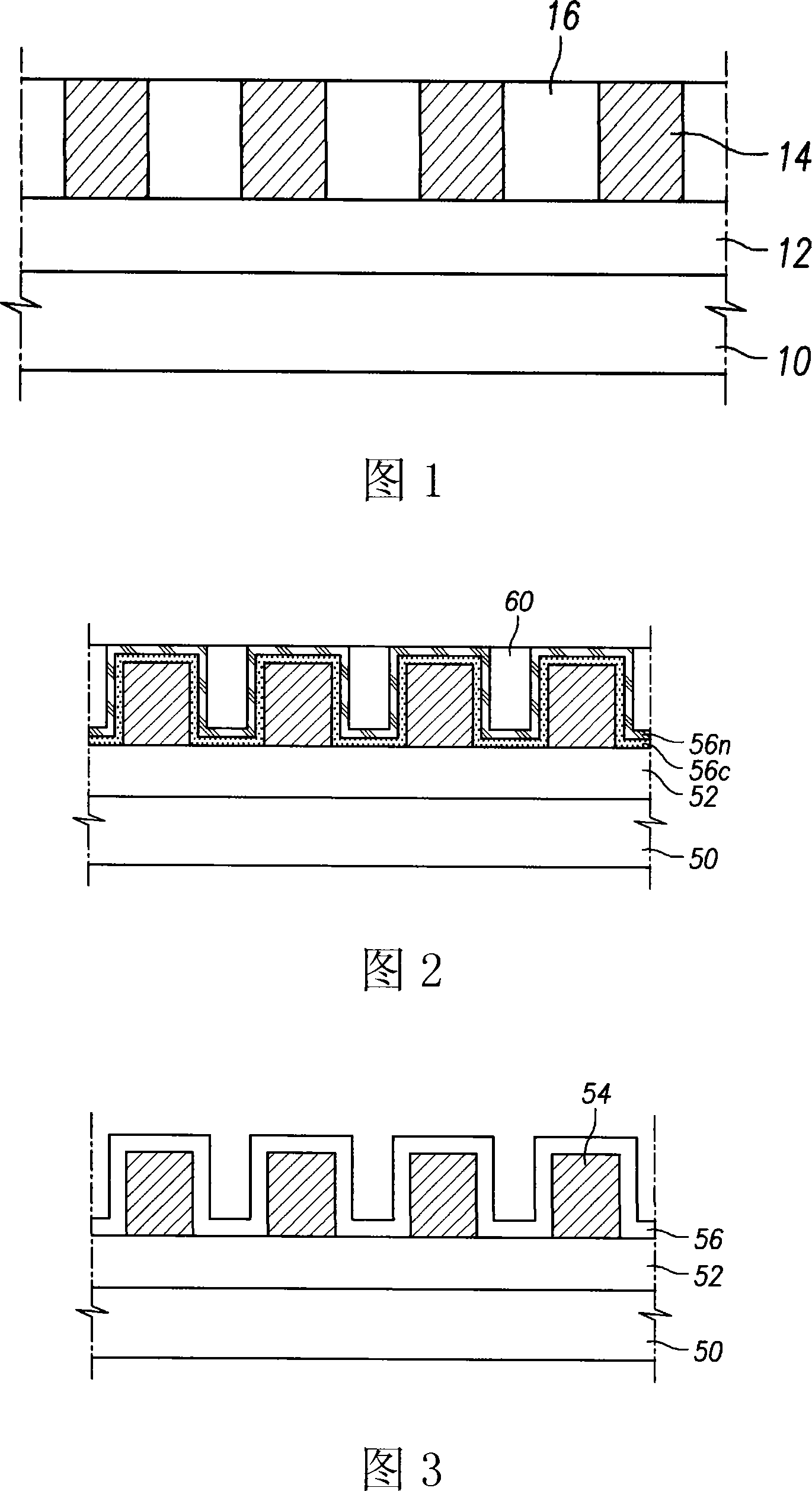

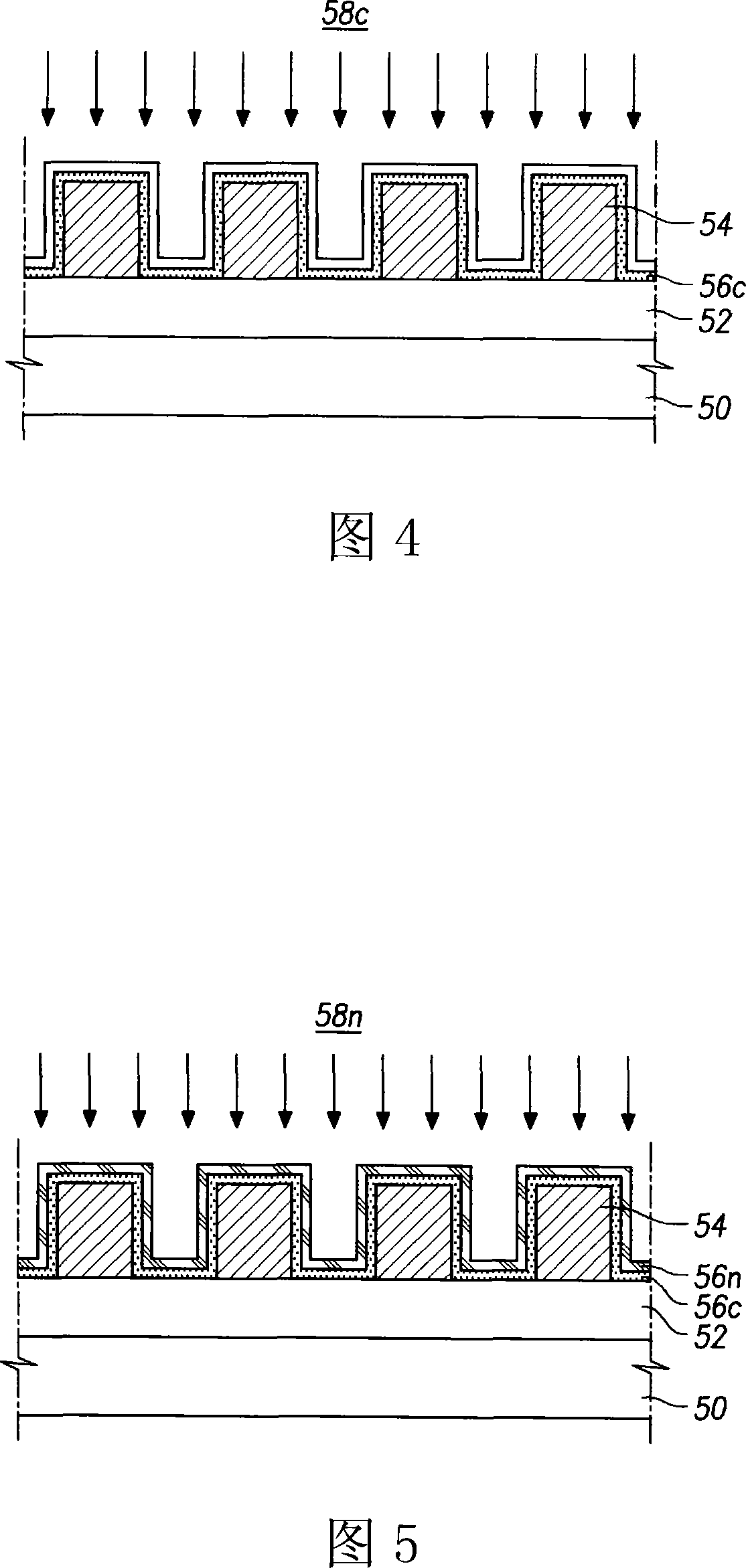

[0015] As shown in the embodiments of FIGS. 2 and 3 , first insulating layer 52 can be formed on and / or over semiconductor substrate 50 . Subsequently, a wire layer having a plurality of wire patterns 54 can be formed on and / or over first insulating layer 52 . The first insulating layer 52 can be used as an interlayer insulating layer to electrically insulate the lower structure from the wiring layer or the covering layer of the gate below the wiring layer.

[0016] The space gap between the respective line patterns 54 can be reduced corresponding to a highly integrated semiconductor device. In a highly integrated semiconductor device requiring a fast operating speed, it is necessary to minimize the parasitic capacitance between the line patterns 54 . To this end, electrical insulation and planarization of the line pattern 54 may be performed. For multiple wire layers, spatial gaps between the wire patterns 54 may be filled with the second insulating layer 60 serving as an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com