Fire-resistant hard foamed polyurethane composite board and fire protection strip preparation method

A technology of rigid polyurethane foam and its production method, which is applied in polyurea/polyurethane adhesives, chemical instruments and methods, fire protection, etc., and can solve the problem of fire protection design and adaptability to construction requirements of external thermal insulation systems of building exterior walls, thermal insulation materials, etc. Melting, large-area fire and other problems, to achieve the effect of mastering the essentials of operation, good flame retardancy, and strong wind pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

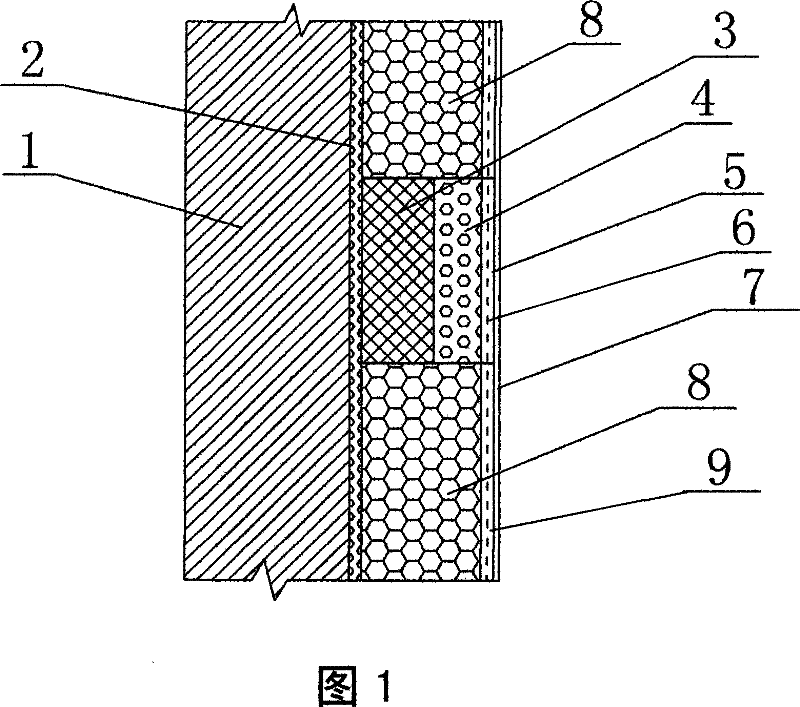

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with specific implementation examples.

[0015] The production method of the fire-resistant rigid foam polyurethane composite board is as follows: the fire-resistant polymer sheet is prepared in advance, and the fire-resistant polymer sheet can be obtained by any of the following methods:

[0016] a. After mixing the inorganic powder and the flame-retardant adhesive in a weight ratio of 3:1, press the mixture with the flame-retardant non-woven fabric with a professional production line to make a flame-retardant polymer sheet.

[0017] b. Immerse the non-woven fabric in the flame-retardant adhesive, take out the non-woven fabric, scrape off the excess flame-retardant adhesive, flatten it, and dry it to form a flame-retardant polymer sheet.

[0018] c. Buy flame-retardant non-woven fabrics on the market

[0019] The flame retardant adhesive is prepared according to the following method: first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com