Forced oscillation direct-action power generation, buffering accumulated energy and electric drive automobile

A technology of automobile and stroke, which is applied in the field of automobile, can solve the problems of reducing engine efficiency, small intake air volume, low compression ratio, etc., and achieve the effect of facilitating the number of working cylinders, reducing mechanical loss and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

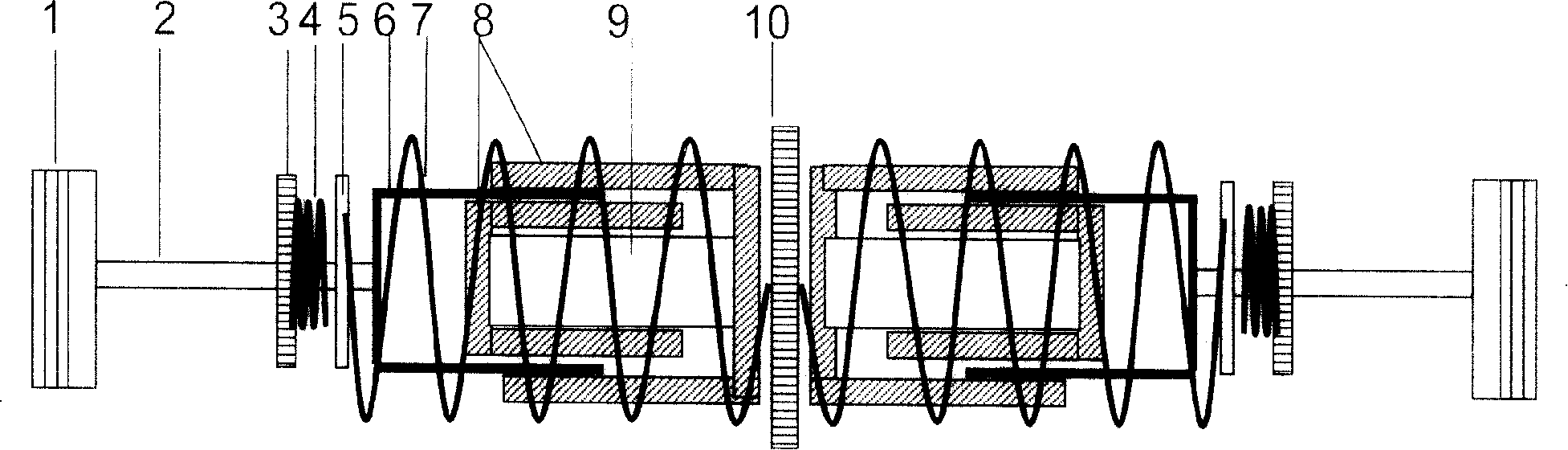

[0020] exist figure 1 Among them, the permanent magnet (9) (or excitation magnet) is connected with the high-permeability body (8), forming a magnetic field in which the magnetic field lines are distributed radially between the high-permeability, the piston (1) and the connecting rod (2), the force plate (5), the moving coil (6), the spring (7) is connected, the other end of the spring (7) is connected with the spring seat (10), the spring (4) is connected with the spring seat (3), and the spring seat (3) is fixed on the body , the central opening is slidably connected with the connecting rod (2). The piston (1), spring (4) and spring (7) form a vibrating system, the reciprocating motion of the piston (1) drives the driving coil (6) to reciprocate in the magnetic field, and the balance position of the piston is near the top dead center of the cylinder.

[0021] Normal operation is divided into four strokes, the first stroke, the intake stroke, the intake valve is opened, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com