Dual spindle differential capacitance type micromechanical accelerameter

A differential capacitor and accelerometer technology, applied in the field of inertial sensors, can solve the problems of elastic support rigidity and excessive cross-coupling, and achieve the effects of reducing processing costs, improving sensitivity and resolution, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

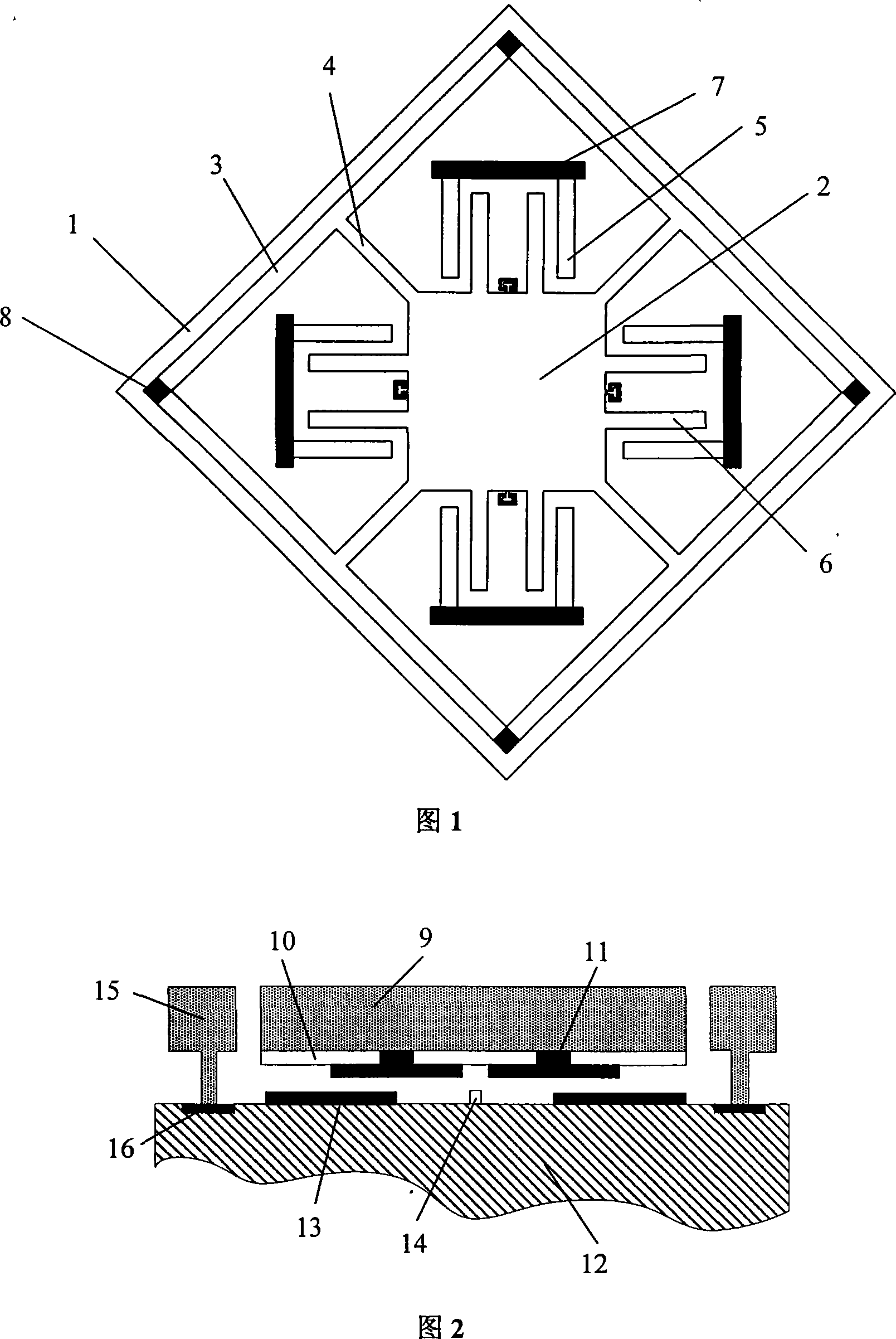

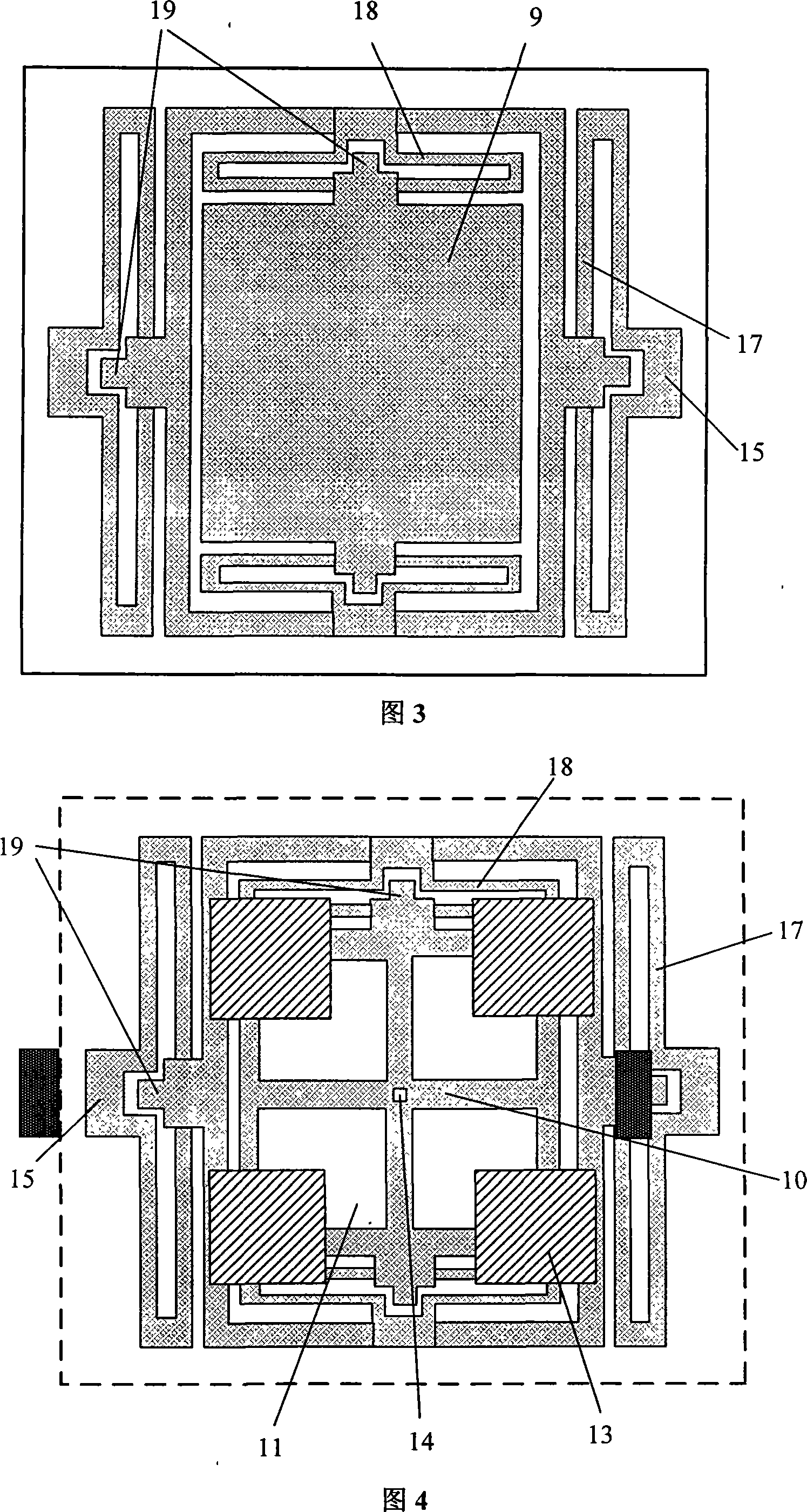

[0022] A biaxial differential capacitive micromachined accelerometer proposed by the present invention is described in detail in conjunction with the accompanying drawings and embodiments as follows:

[0023] The structure of the present invention is shown in Fig. 2, Fig. 3, Fig. 4, comprises mass block 9, insulating layer 10, movable electrode 11, substrate 12, fixed electrode 13, protruding anti-absorption stopper 14, column 15, Movable electrode leads 16, transverse folded beams 17, longitudinal folded beams 18, convex anti-shock stops 19. The mass block 9 is composed of a silicon wafer as the main body and adopts an overall square shape. A square array composed of four square movable electrodes 11 is arranged in a square array on the silicon wafer. The center of the electrode array coincides with the center of the silicon wafer. The insulating layer 10 is isolated, and the horizontal ends of the mass block 9 are fixed on the longitudinal folding beam 18 to form a longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com