Rotational flow type mineral dressing separating and processing method

A separation treatment and swirling technology, which is applied in the direction of solid separation, wet separation, swirling devices, etc., can solve the problems of wasting power and high cost of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

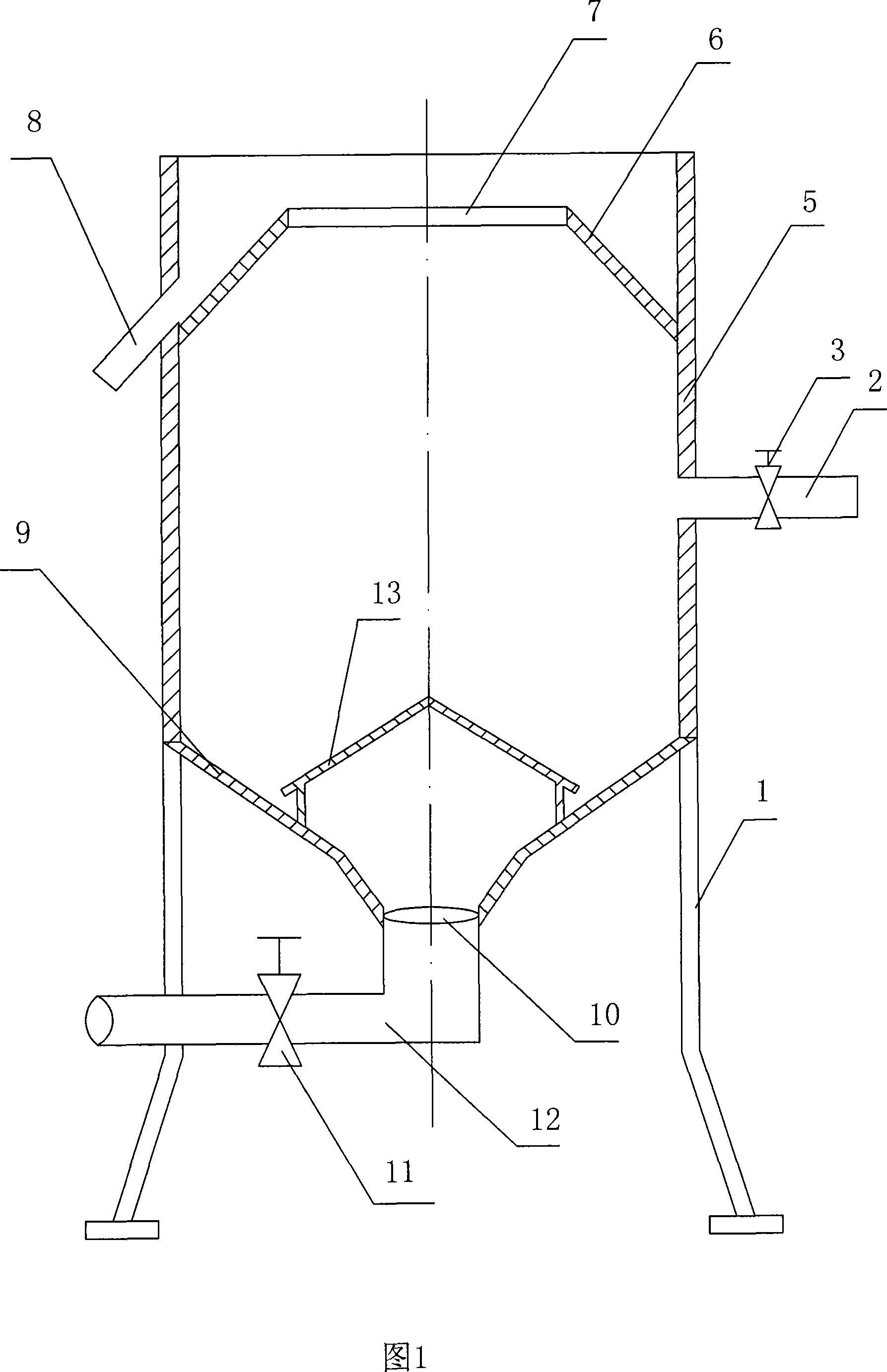

[0022] As shown in Figure 1, the cyclone separation treatment method is to inject ore pulp and clear water into the circular separator 5, so that the ore slurry mixture in the circular separator 5 is rotated to separate metals, non-metals and harmful substances.

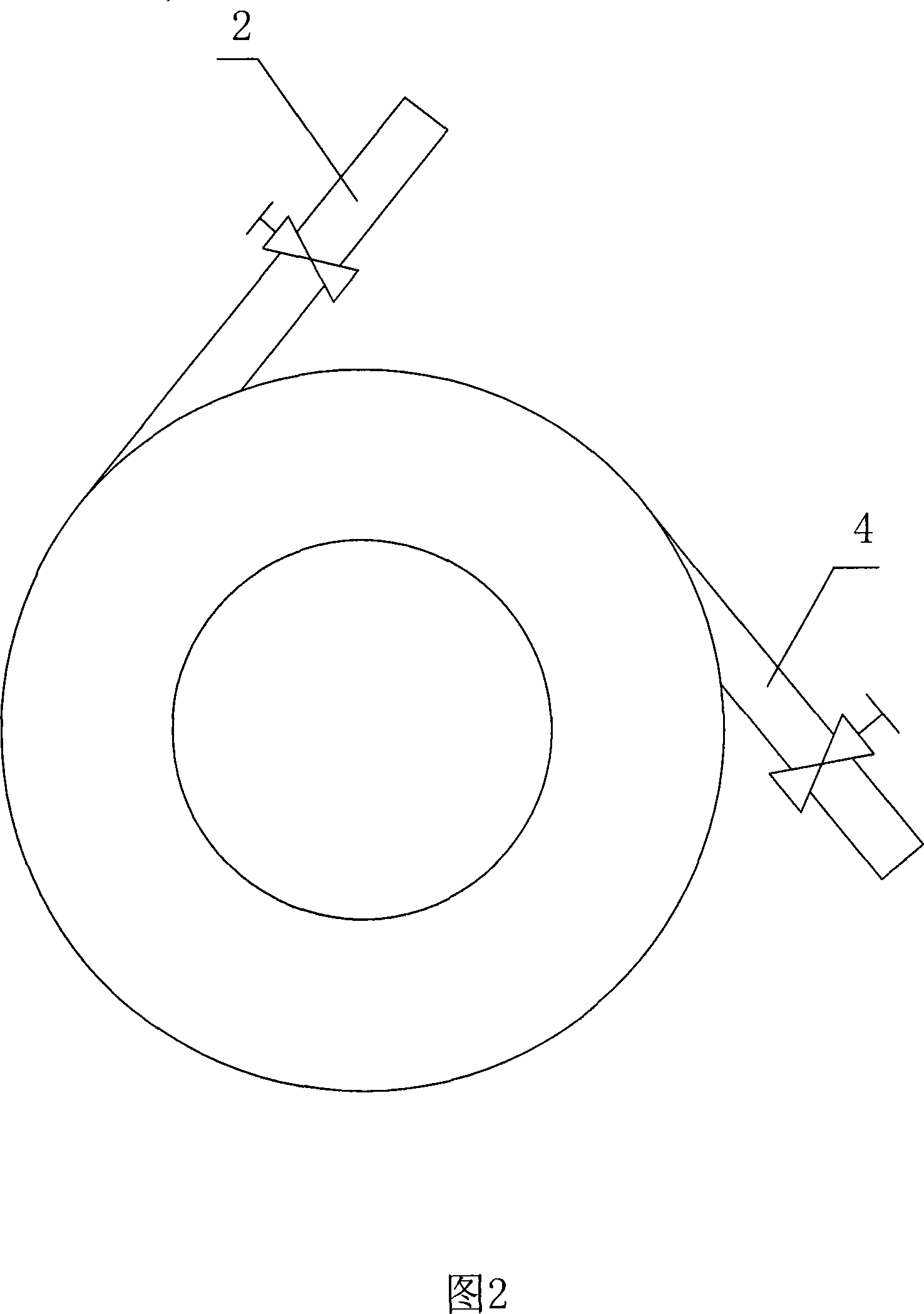

[0023] As shown in Figure 2, the above-mentioned ore slurry and clear water are injected into the circular body separator 5 at an angle consistent with the tangent line of the circular body separator 5; non-metallic and harmful substances pass through the top of the circular body separator 5, The upper discharge port 7 formed by the top of the baffle plate 6 fixedly connected to the inclined inner wall is thrown out by the centripetal force generated by the rotation of the slurry mixture due to the driving force when the slurry and clean water are injected; The lower discharge port 10 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com