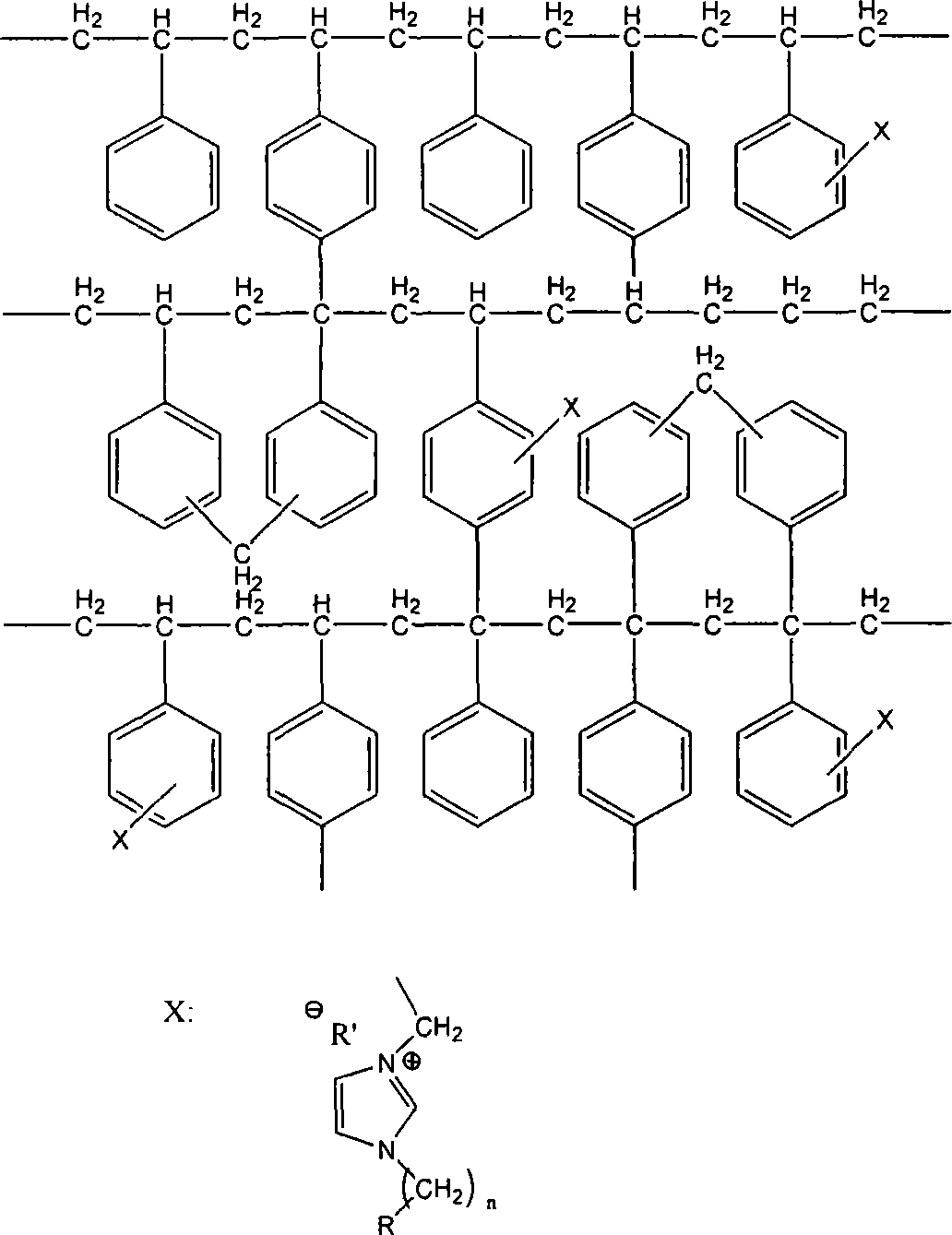

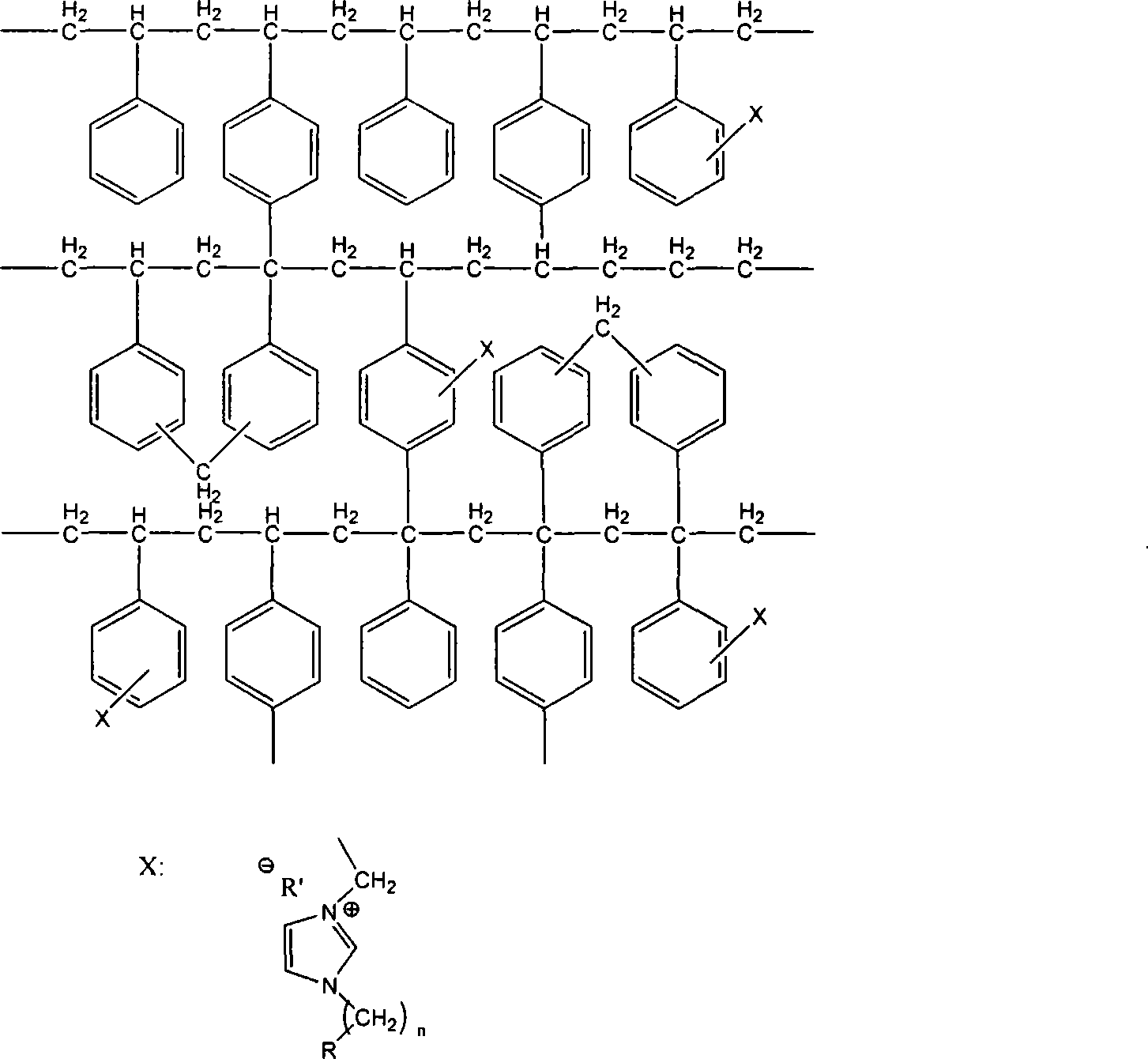

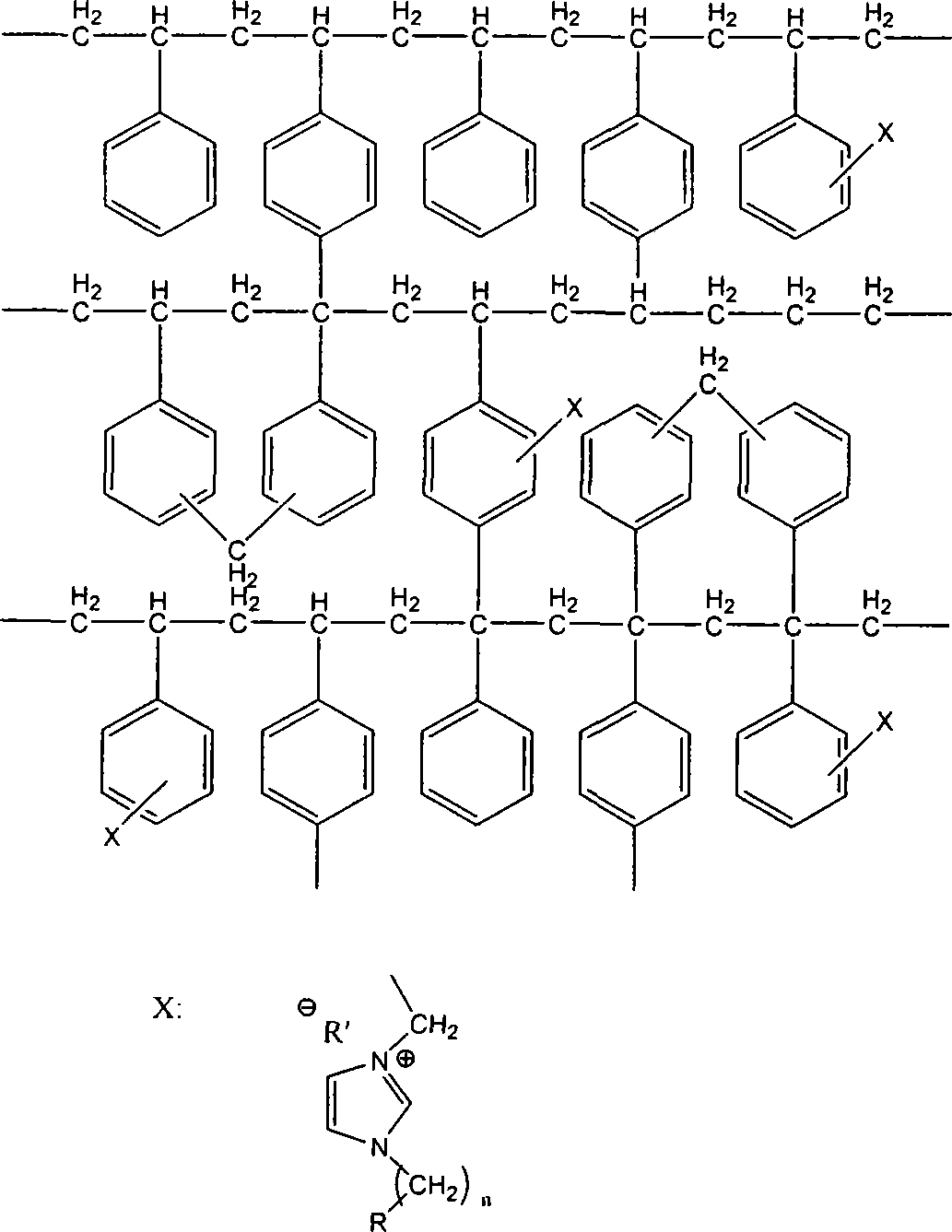

Imidazolyl modified complex functional high-crosslinked adsorption resin and preparation method thereof

A composite function, ultra-high cross-linking technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of single coordination, no microporous structure, low cross-linking degree, etc., and achieve improved thermal stability , good affinity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 30g of chlorine balls with a cross-linking degree of 8% (produced by Hebei Langfang Electric Power Resin Factory, etc., with a chlorine content of 18%), add 60ml of nitrobenzene and dissolve it in a 250ml three-necked bottle for 12h; heat up at a speed of 1°C / 2min to 80°C, add 2g of zinc chloride at a certain stirring speed, and continue the reaction until the residual chlorine content of the resin is 12%; exhaust the reaction mother liquor, and wash the polystyrene resin with 600ml of methylal and methanol. Add 60ml of nitrobenzene to swell for 12 hours; control the temperature of the solution at 40°C, and continuously add 80ml of methylimidazole dropwise at a stirring speed of 110rpm to continue the reaction for 8 hours, take it out and filter, rinse with 4% hydrochloric acid, extract, and dry. The resulting product is methylimidazole-modified composite functional ultra-high cross-linked adsorption resin, the resin methylimidazole content is 4.9mmol / g, and the mic...

Embodiment 2

[0031] Take 30g of chlorine balls with a cross-linking degree of 8% (produced by Hebei Langfang Electric Power Resin Factory, etc., with a chlorine content of 18%), add 150ml of nitrobenzene and dissolve it in a 500ml three-necked bottle for 18h; heat up at a speed of 1°C / 4min To 120°C, add 15g of tin chloride at a certain stirring speed, and continue the reaction until the residual chlorine content of the resin is 4%; exhaust the reaction mother liquor, and wash the polystyrene resin with 2L of ethanol and acetone. Add 150ml of nitrobenzene to swell for 8 hours; control the temperature of the solution to 70°C, and continuously add 15ml of imidazole acetate dropwise at a stirring speed of 50rpm to continue the reaction for 6 hours, take it out and filter, rinse with 5% sodium bicarbonate, extract, and dry Dry, the resulting product is imidazole acetate modified composite function ultra-high cross-linked adsorption resin, the imidazole acetate content of the resin is 0.15mmol / g,...

Embodiment 3

[0033]Take 30g of chlorine balls with a cross-linking degree of 8% (produced by Hebei Langfang Electric Power Resin Factory, etc., with a chlorine content of 18%), add 120ml of dichloroethane and swell in a 500ml three-necked bottle for 10h; at a speed of 1°C / 6min Raise the temperature to 40°C, add 9g of ferric chloride at a certain stirring speed, and continue the reaction until the residual chlorine content of the resin is 9%; exhaust the reaction mother liquor, and wash the polystyrene resin with 500ml of acetone. Add 120ml of dichloroethane to swell for 10 hours; control the temperature of the solution at 50°C, and continuously drop 60ml of imidazole at a stirring speed of 90rpm to continue the reaction for 6 hours, take it out and filter, rinse with 7% phosphoric acid, extract, and dry. The obtained product is an imidazole group-modified composite function ultra-high cross-linked adsorption resin, the content of the imidazole group in the resin is 3.1mmol / g, and the microp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com