The preparation method of silver powder

A technology of silver powder and silver nitrate, which is used in metal processing equipment, transportation and packaging, etc., can solve the problems of affecting the performance of silver powder, inability to settle, and high proportion of organic residues on the surface of silver powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

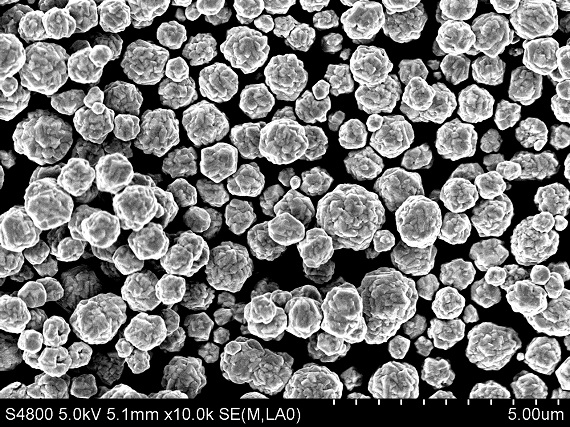

Image

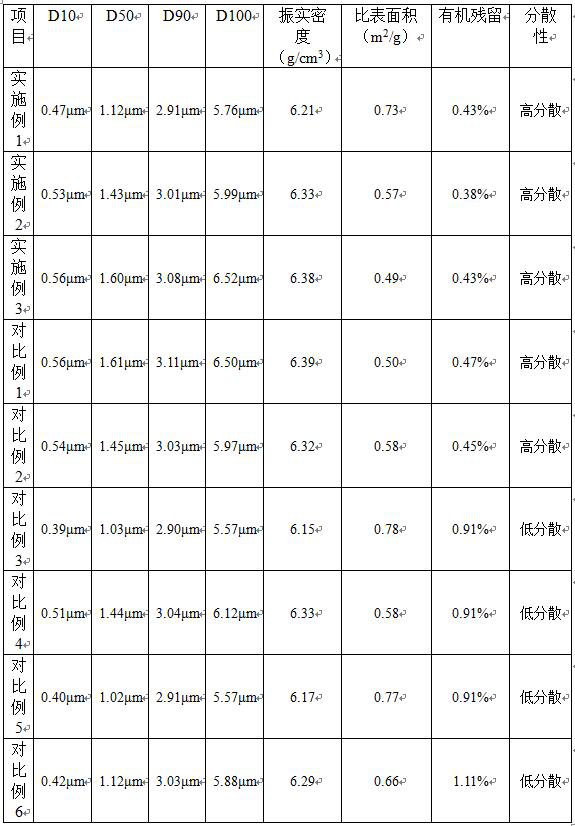

Examples

Embodiment 1

[0032] A preparation method of silver powder, comprising the following steps:

[0033] (1) Take 60L of deionized water and 4Kg of silver nitrate, the concentration of silver nitrate is 0.5mol / L, stir evenly, add 250g of gum arabic, and stir to dissolve at 25°C to obtain solution A;

[0034] Take 60L of deionized water and 4Kg of ascorbic acid, mix them evenly, add 360g of gum arabic, and stir at 30°C until dissolved to obtain solution B;

[0035] (2) Take solution B, add solution B to solution A at a rate of 2 L / min, and complete the reaction at 50 °C to obtain suspension C;

[0036] (3) Take 24kg of sodium hydroxide and configure it into a 50% concentration sodium hydroxide solution; add a 50% concentration sodium hydroxide solution to the suspension C to adjust the pH to 14, heat up to 65°C, keep stirring for 0.5h , after the supernatant is clarified, extract the supernatant, collect silver powder, wash, suction filter, and dry to obtain the finished product.

Embodiment 2

[0038] A preparation method of silver powder, comprising the following steps:

[0039] (1) Take 60L of deionized water and 4Kg of silver nitrate, the concentration of silver nitrate is 0.5mol / L, stir evenly, add 250g of gum arabic, and stir at 32°C to a dissolved state to obtain solution A;

[0040] Take 60L of deionized water and 4Kg of ascorbic acid, mix them evenly, add 360g of gum arabic, and stir at 34°C until dissolved to obtain solution B;

[0041](2) Take solution B, add solution B to solution A at a rate of 2.5L / min, and complete the reaction at 55°C to obtain suspension C;

[0042] (3) Take 24kg of sodium hydroxide and configure it into a 50% concentration sodium hydroxide solution; add a 50% concentration sodium hydroxide solution to the suspension C to adjust the pH to 14, heat to 72°C, keep stirring for 1.5h , after the supernatant is clarified, extract the supernatant, collect silver powder, wash, suction filter, and dry to obtain the finished product.

Embodiment 3

[0044] A preparation method of silver powder, comprising the following steps:

[0045] (1) Take 60L of deionized water and 4Kg of silver nitrate, the concentration of silver nitrate is 0.5mol / L, stir evenly, add 250g of gum arabic, and stir to dissolve at 35°C to obtain solution A;

[0046] Take 60L of deionized water and 4Kg of ascorbic acid, mix them evenly, add 360g of gum arabic, and stir to dissolve at 35°C to obtain solution B;

[0047] (2) Take solution B, add solution B to solution A at a rate of 3 L / min, and complete the reaction at 60 °C to obtain suspension C;

[0048] (3) Take 24 kg of sodium hydroxide and configure it into a 50% concentration sodium hydroxide solution; add a 50% concentration sodium hydroxide solution to the suspension C to adjust the pH to 14, heat up to 75°C, keep stirring for 2h, After the supernatant is clarified, the supernatant is extracted, silver powder is collected, washed, filtered and dried to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com