Minitype air-supply machine

An air supply machine, small technology, used in mechanical equipment, machines/engines, liquid variable capacity machines, etc., can solve the problems of troublesome, unstable, and difficult to meet standard requirements, and achieves compact structure, easy portability, and operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

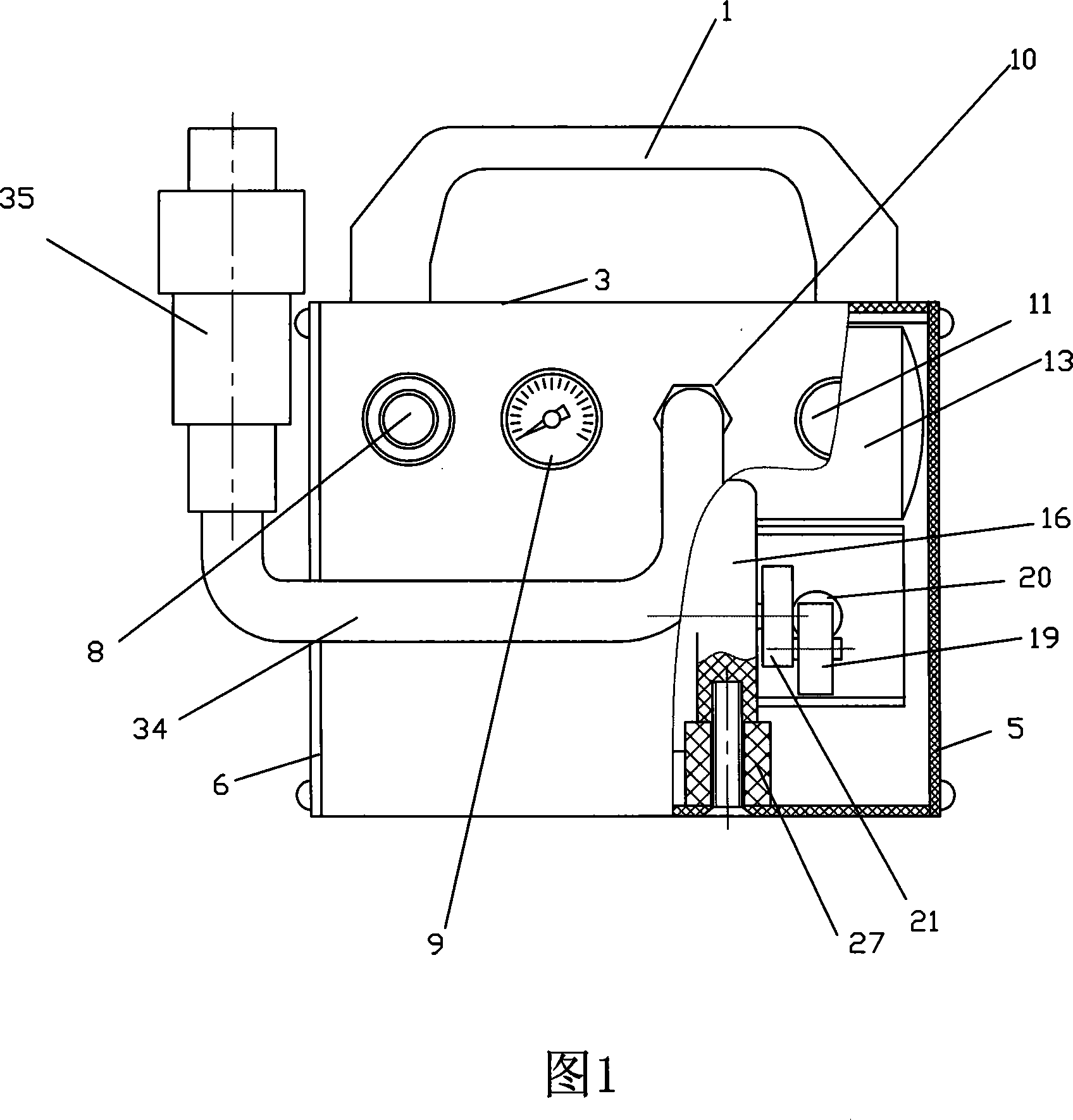

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] As shown in Figures 1 and 2, the upper part of the casing 3 of the small air supply machine is equipped with a handle 1, and the parts such as the motor 16, the gas making mechanism and the gas storage tank 13 are all placed in the casing 3, and the two ends of the casing 3 are connected with the left , The right machine cover 6,5 is closed.

[0019] The above-mentioned casing 3 can be drawn by aluminum alloy profiles, and the casing can be provided with concave-convex curves for increasing the appearance, and rubber feet are installed at the bottom.

[0020] Air vents can be established on the left and right machine covers 6,5.

[0021] There is a pen holder 8 on the casing 3, which is used to place a pen-like object, and does not need to be equipped with an airbrush stand in addition when used as a small-sized air supply machine.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com