Single mode fibre with low bending loss and low nonlinear effect

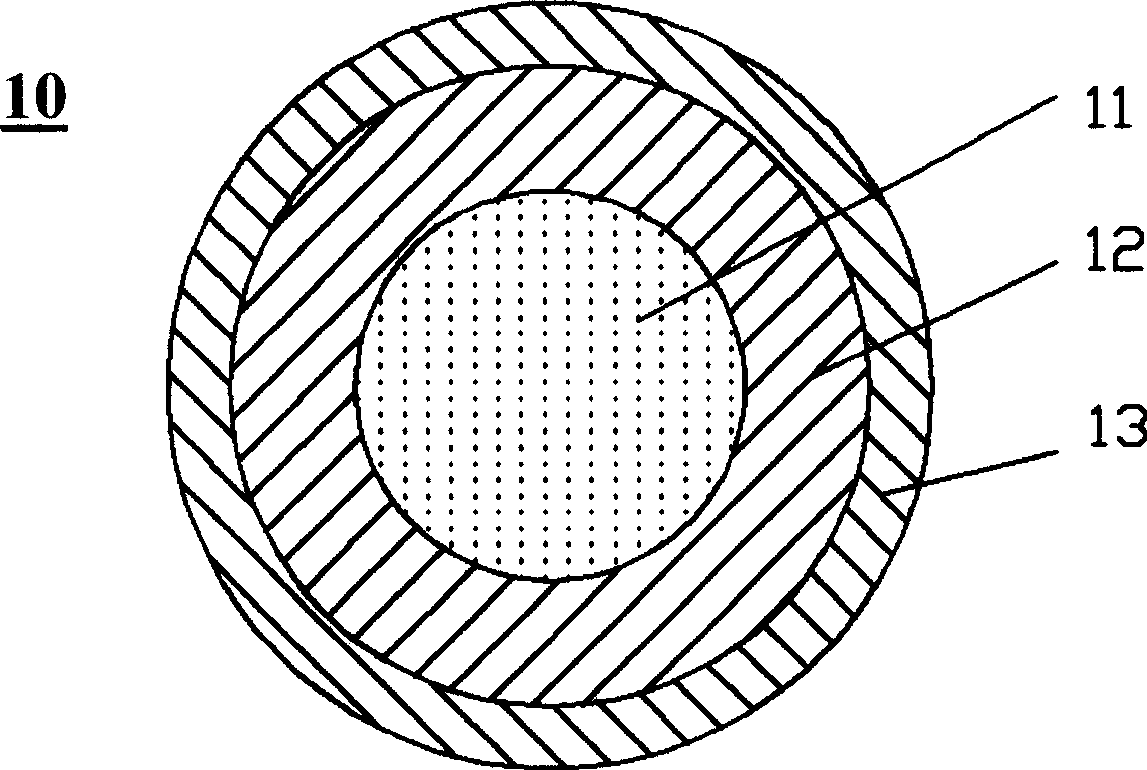

A non-linear effect, bending loss technology, applied in the direction of multi-layer core/cladding fiber, cladding fiber, optical waveguide light guide, etc. Low nonlinear effects, relaxed manufacturing tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

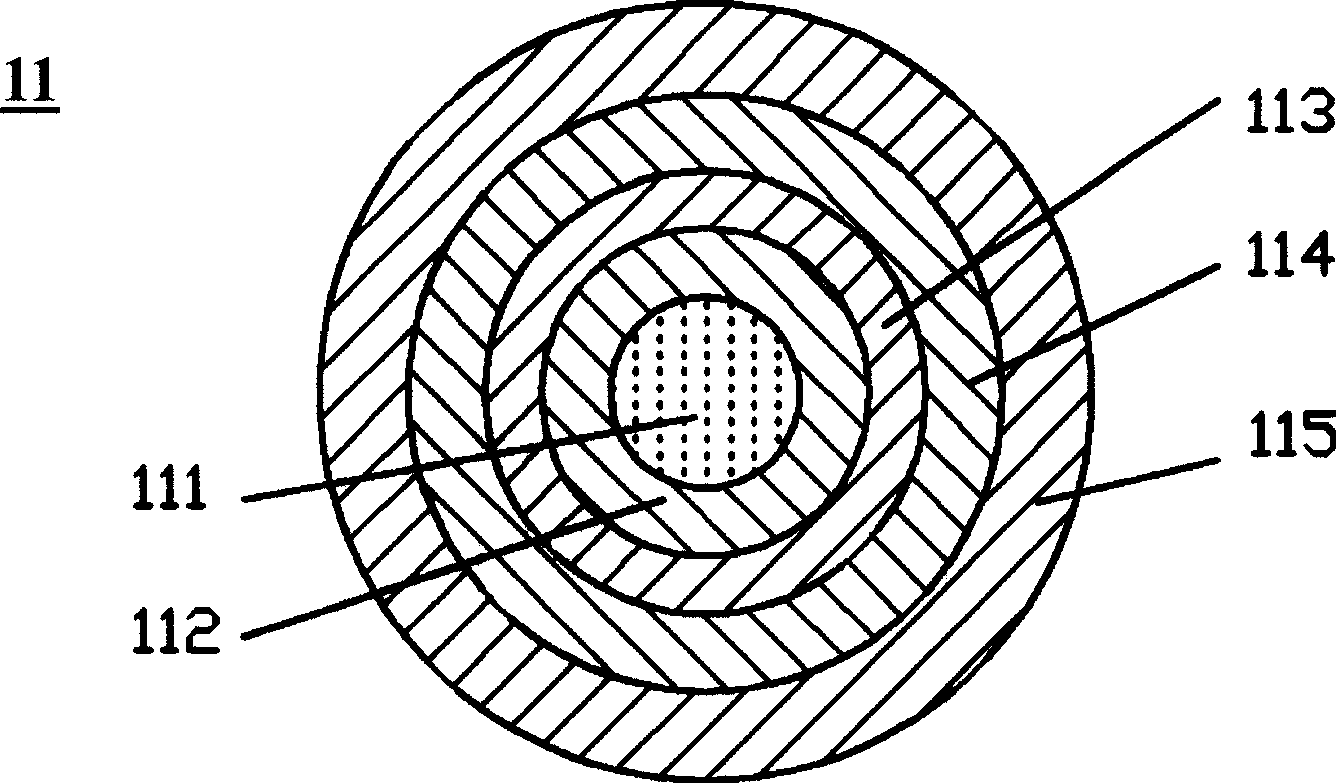

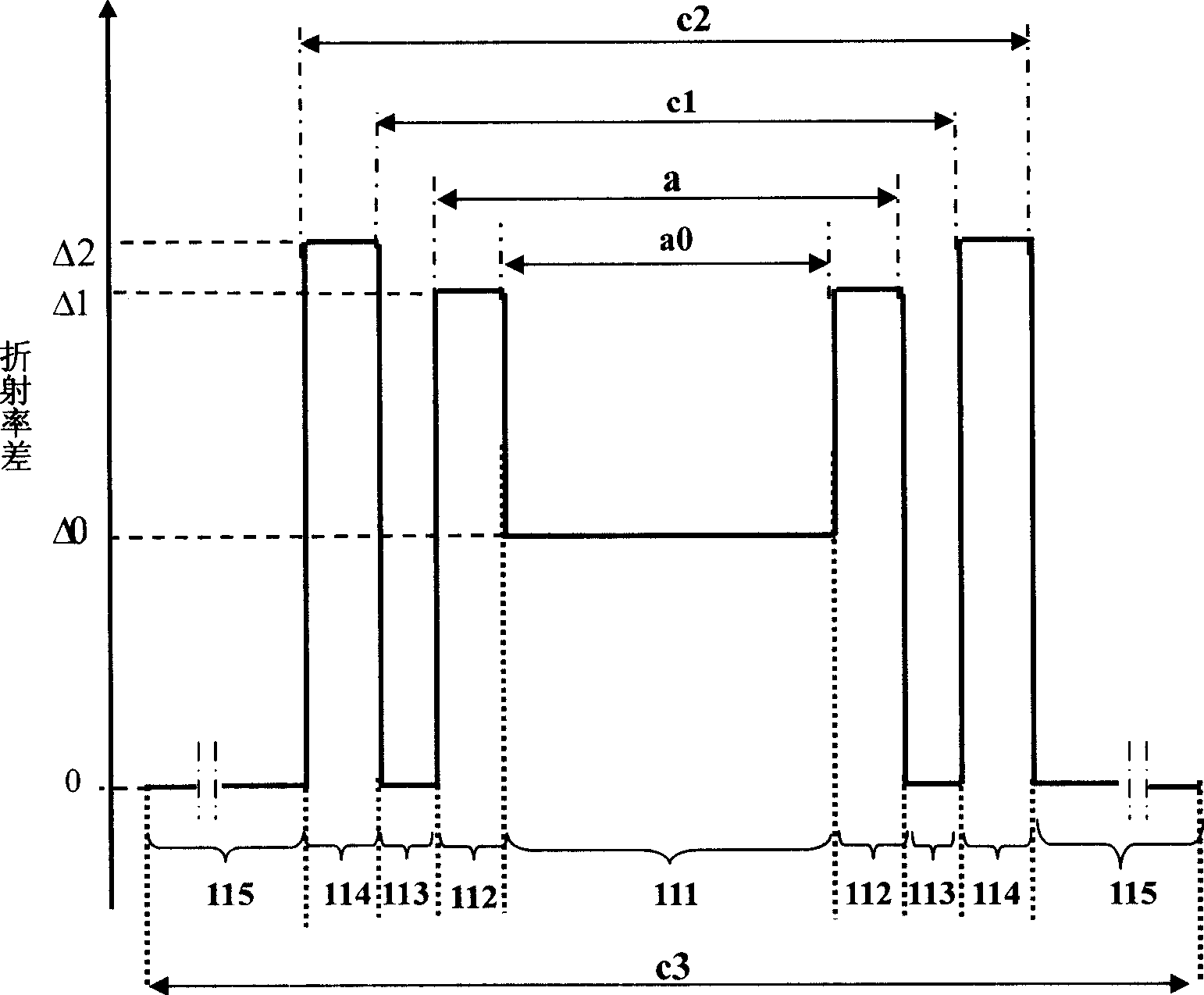

Embodiment 1

[0085] MCVD (or PCVD) is used to manufacture the core rod, and OVD (or RIC) technology is used to manufacture the outer cladding to manufacture the optical fiber preform. When depositing the recessed region 111 of the core layer, the raw material SiCl 4 Doped with a certain amount of GeCl 4 Make the value of the refractive index difference Δc in the depressed region of the core layer 0.0038 at a wavelength of 632.8 nm; when depositing the non-recessed region 112 of the core layer, adjust the GeCl 4 The doping amount makes the value of the refractive index difference Δ1 in the non-recessed region of the core layer 0.0094 at a wavelength of 632.8nm; when depositing the first cladding region 113, use pure SiCl 4 Raw material; when depositing the second cladding region 114, the raw material SiCl 4 Doped with a certain amount of GeCl 4 Make the value of the second cladding refractive index difference Δ2 at a wavelength of 632.8nm 0.010; when depositing the third cladding region ...

Embodiment 2

[0087] MCVD (or PCVD) is used to manufacture the core rod, and OVD (or RIC) technology is used to manufacture the outer cladding to manufacture the optical fiber preform. When depositing the recessed region 111 of the core layer, the raw material SiCl 4 Doped with a certain amount of GeCl 4 Make the value of the refractive index difference Δc in the depressed region of the core layer 0.0035 at a wavelength of 632.8 nm; when depositing the non-recessed region 112 of the core layer, adjust the GeCl 4 The doping amount of the core layer makes the value of the refractive index difference Δ1 of the non-recessed region of the core layer 0.0088 at a wavelength of 632.8nm; when depositing the first cladding region 113, use pure SiCl 4 Raw material; when depositing the second cladding region 114, the raw material SiCl 4 Doped with a certain amount of GeCl 4 The value of the second cladding refractive index difference Δ2 at a wavelength of 632.8nm is 0.0097; when depositing the third...

Embodiment 3

[0089] MCVD (or PCVD) is used to manufacture the core rod, and OVD (or RIC) technology is used to manufacture the outer cladding to manufacture the optical fiber preform. When depositing the recessed region 111 of the core layer, the raw material SiCl 4 Doped with a certain amount of GeCl 4 Make the value of the refractive index difference Δc in the depressed region of the core layer 0.0073 at a wavelength of 632.8 nm; when depositing the non-recessed region 112 of the core layer, adjust the GeCl 4 The doping amount of the core layer makes the value of the refractive index difference Δ1 of the non-recessed region of the core layer 0.0088 at a wavelength of 632.8nm; when depositing the first cladding region 113, use pure SiCl 4 Raw material; when depositing the second cladding region 114, the raw material SiCl 4 Doped with a certain amount of GeCl 4 The value of the second cladding refractive index difference Δ2 at a wavelength of 632.8nm is 0.0010; when depositing the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com