Control system and method of multisolt multifunctional chemical reactor

A chemical reactor and control system technology, applied in the direction of chemical instruments and methods, general control systems, control/regulation systems, etc., can solve the problem of not being able to provide a completely independent operating environment for chemical reactions, inconvenient operation, and large space required, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

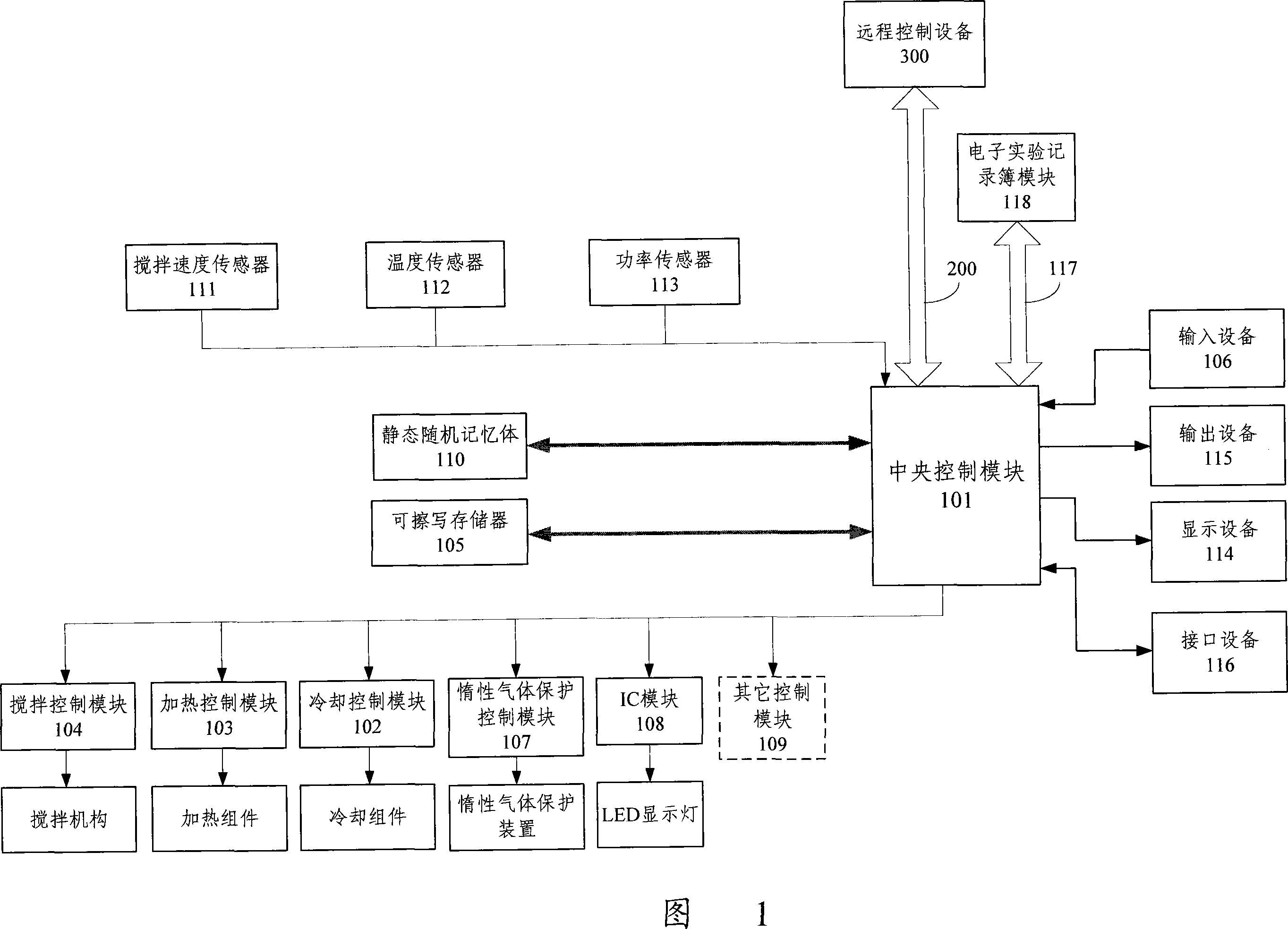

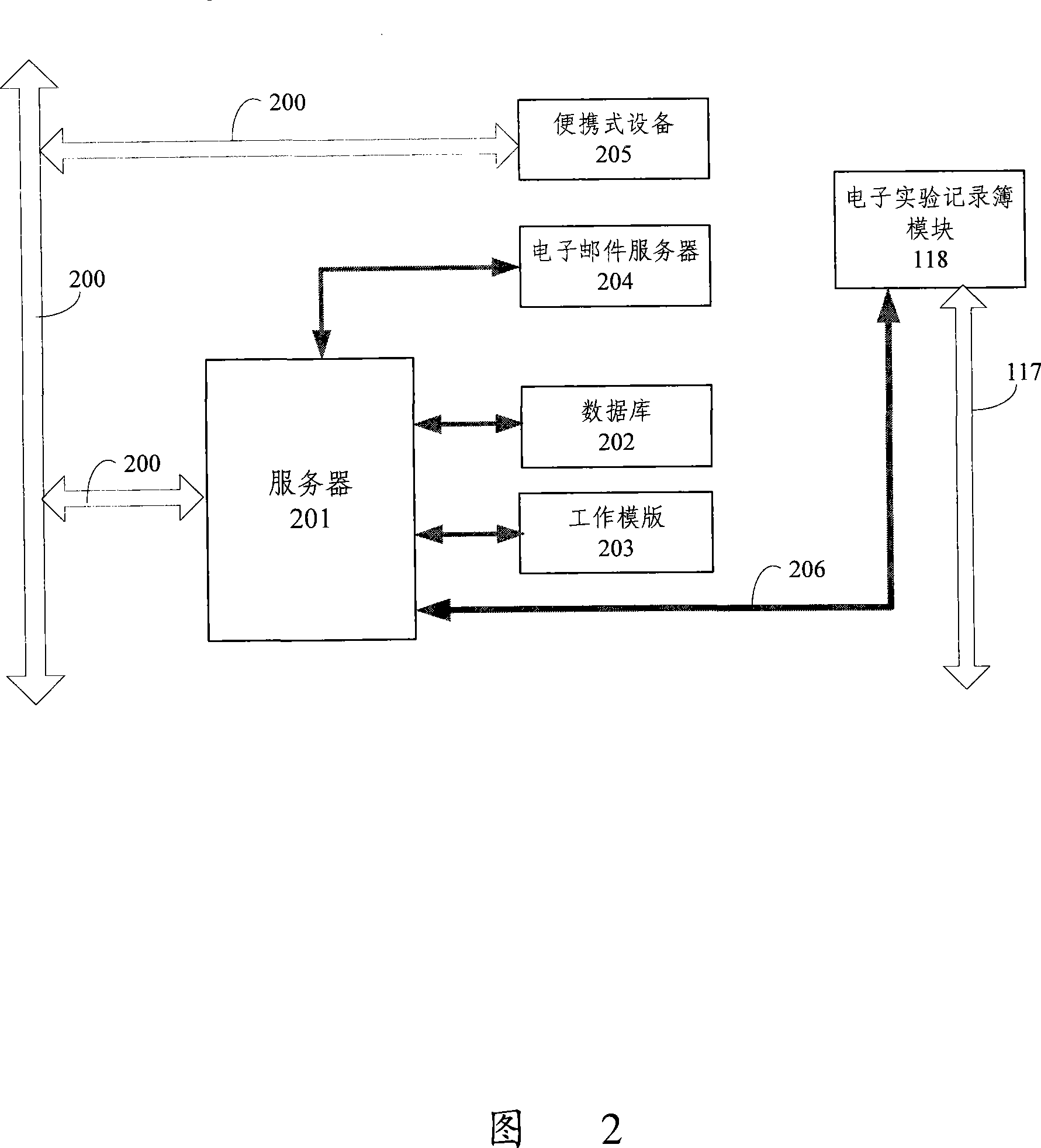

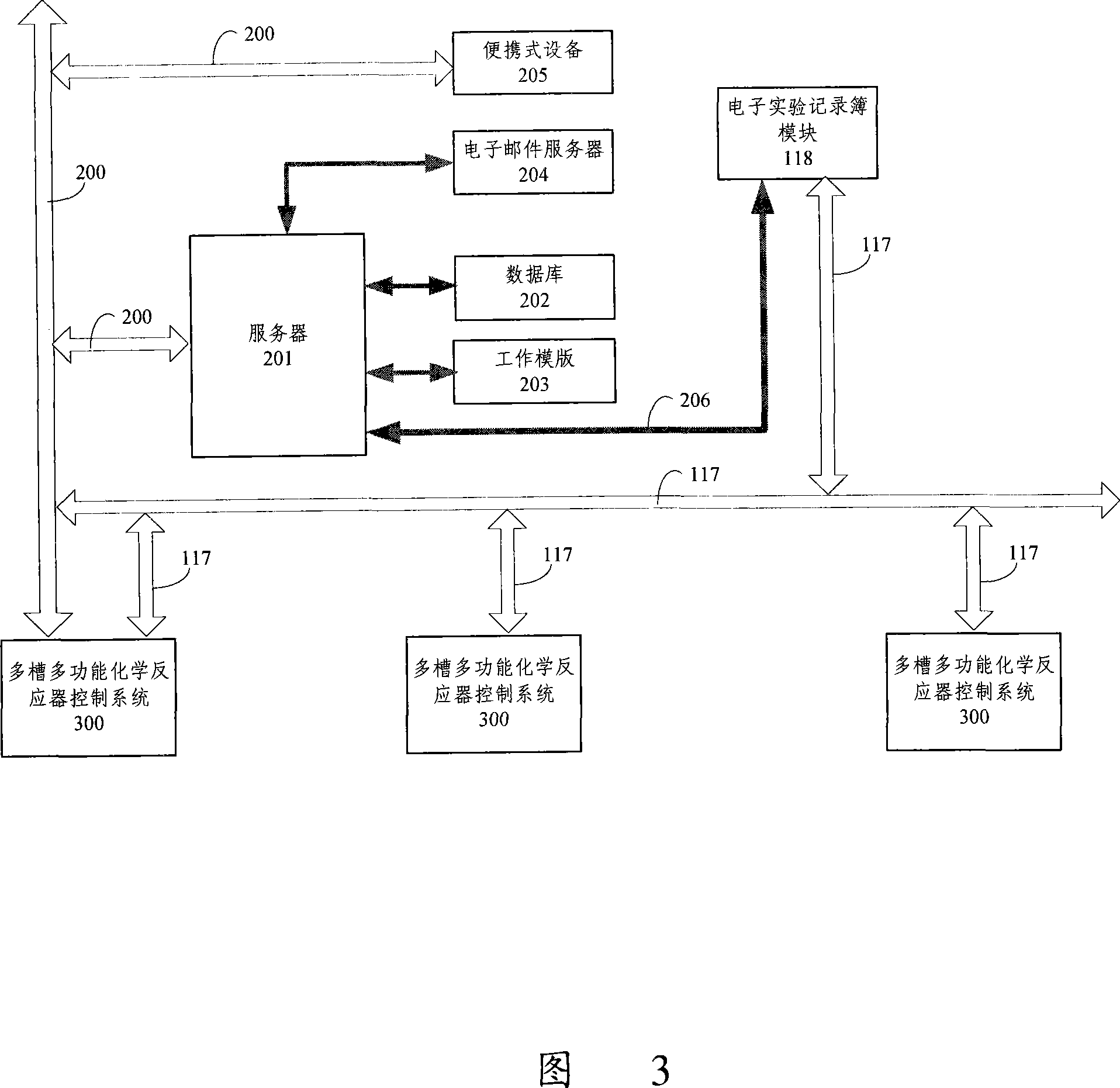

[0089] The present invention will be further described in detail below through specific embodiments and accompanying drawings.

[0090] The control system and method described in the present invention drive a multi-slot multifunctional chemical reaction synthesizer, and the multi-slot multifunctional chemical reaction synthesizer includes a main body and at least includes an independent workstation. Each workstation can be equipped with multiple chemical reactors, and one chemical reactor is a chemical reaction tank.

[0091] Each workstation is equipped with at least one set of cooling components to form a functional connection with the workstation, and is used for independent cooling and temperature control of the reaction tank of the workstation. Each group of cooling components includes a cooling component connected to the workstation, and also includes at least one inlet for injecting phase-change refrigerant, a heat absorption area, and at least one outlet for removing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com