Method for preparing high-purity beta-elemene by citronella oil byproduct

A technology of by-product, citronella oil, applied in distillation purification/separation, organic chemistry and other directions, can solve the problems of poor extraction stability of instruments and equipment, complex production equipment, limited source of raw materials, etc., to improve production efficiency and simple production operation steps , the effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

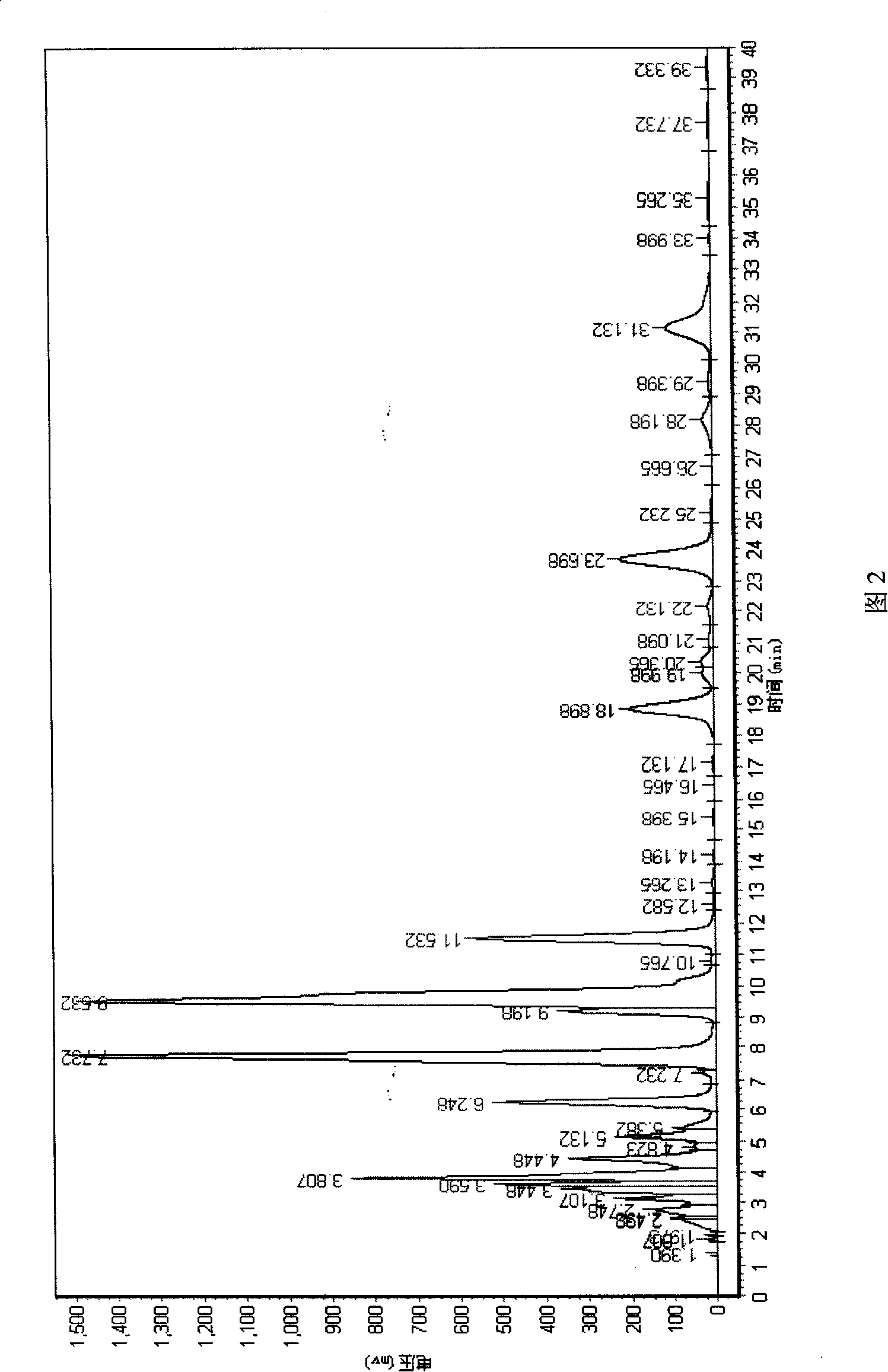

[0031] A, get citronella oil by-product as raw material (beta-elemene content<5%);

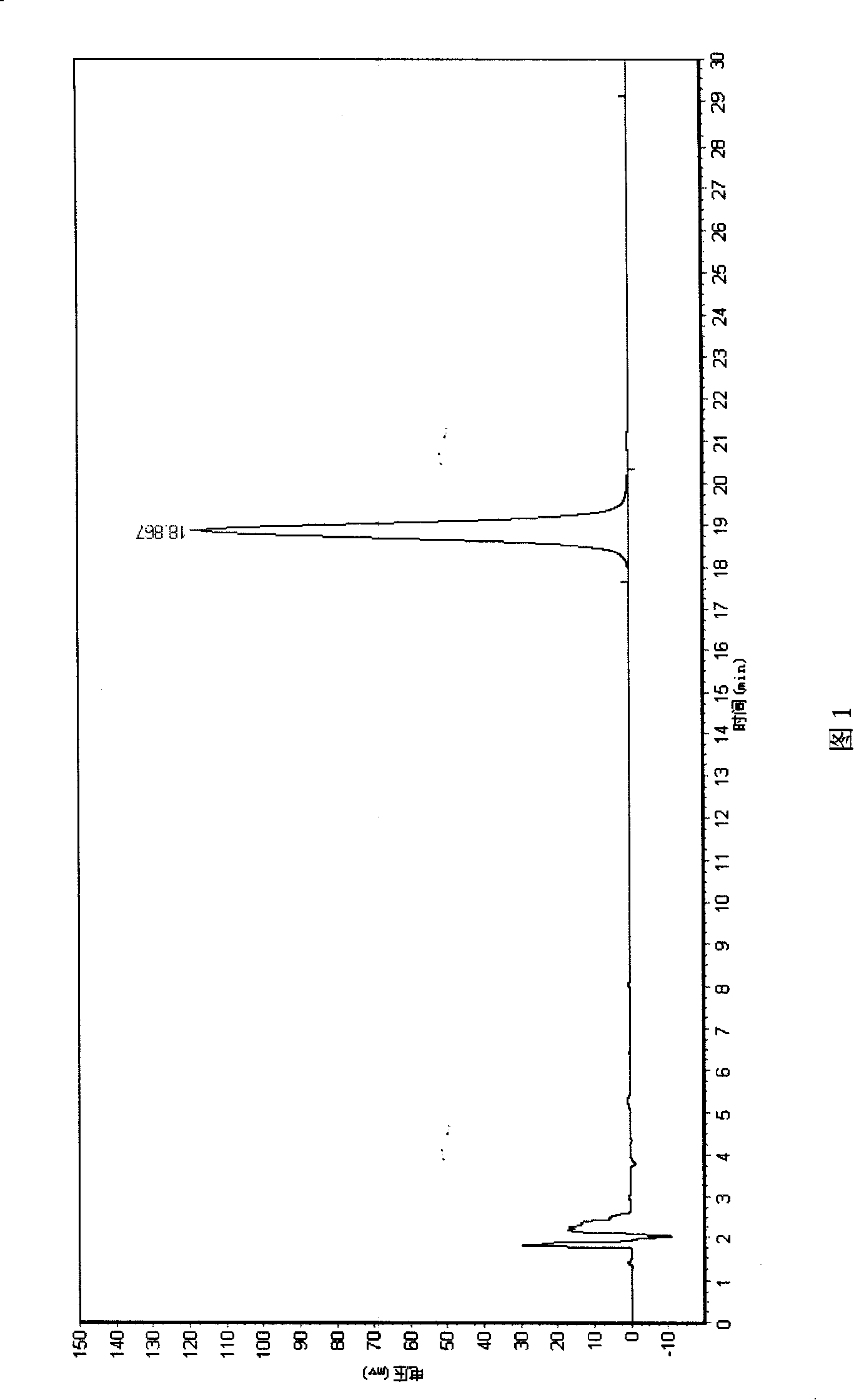

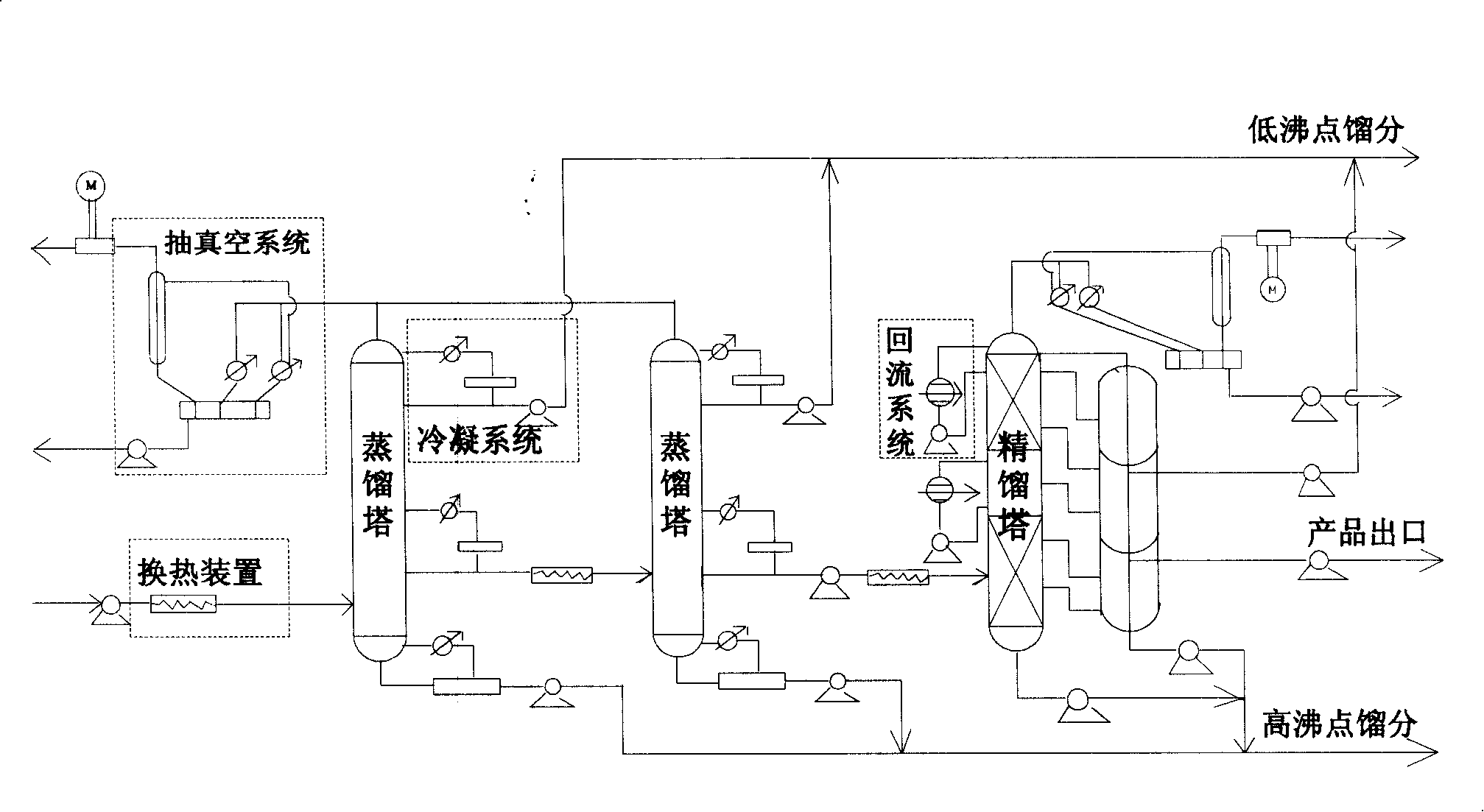

[0032] b, put an appropriate amount of citronella oil by-products into a 3L vacuum still, turn on the condensed water for cooling, turn on the vacuum pump and heating device, control the vacuum to be 4-5mm Hg, and when the temperature of the heating kettle is 100°C, Distill all the initial fraction at 48-76°C; adjust the temperature of the heating tank to 138°C, collect the fraction at 88-110°C to obtain a primary distillation product;

[0033] c. Put the primary distillation product obtained in step b into a vacuum still, control the vacuum of the whole system to carry out vacuum distillation at 4-5mm Hg, and when the temperature of the vacuum still is 112°C, set the temperature at 77 The initial fraction at -91°C is all distilled; adjust the temperature of the vacuum still to 135°C, collect the fraction at 96-104°C, and obtain the secondary distillation product;

[0034] d. Put the secondar...

Embodiment 2

[0036] A, get citronella oil by-product as raw material (beta-elemene content<5%);

[0037] b, put an appropriate amount of citronella oil by-products into a 3L vacuum still, turn on the condensed water for cooling, turn on the vacuum pump and heating device, control the vacuum to be 1-2mm Hg, and when the temperature of the heating kettle is 92°C, Distill all the initial fraction at 40-70°C; adjust the temperature of the heating tank to 128°C, collect the fraction at 80-100°C, and obtain a primary distillation product;

[0038] c. Put the primary distillation product obtained in step b into a vacuum still, control the vacuum of the whole system to carry out vacuum distillation at 1-2mm Hg, when the temperature of the vacuum still is 102°C, set the temperature at 72 The initial fraction at -83°C is all distilled; adjust the temperature of the vacuum still to 124°C, collect the fraction at 88-94°C, and obtain the secondary distillation product;

[0039] d. Put the secondary di...

Embodiment 3

[0041] A, get citronella oil by-product as raw material (beta-elemene content<5%);

[0042] B, an amount of citronella oil by-products are packed in the decompression distillation still of L, open condensed water and cool off, open vacuum pump and heating device, control vacuum tightness is 9-10mm Hg, when the temperature of heating still is 105 ℃, Distill all the initial fraction at 56-85°C; adjust the temperature of the heating tank to 154°C, collect the fraction at 95-120°C, and obtain a primary distillation product;

[0043]c. Put the primary distillation product obtained in step b into a vacuum still, control the vacuum of the whole system to carry out vacuum distillation at 9-10mmHg, and when the temperature of the vacuum still is 113°C, set the temperature at 85- All the initial fractions at 98°C are distilled; adjust the temperature of the vacuum still to 155°C, collect the fractions at 112-120°C, and obtain the secondary distillation product;

[0044] d. Put the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com