Decompression drying device

A technology of decompression drying device and decompression mechanism, which is applied in the directions of drying solid materials, heating to dry solid materials, and drying. Larger and other problems, to achieve the effect of rapid decompression drying treatment and heat treatment, reduced occupied area, and small waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

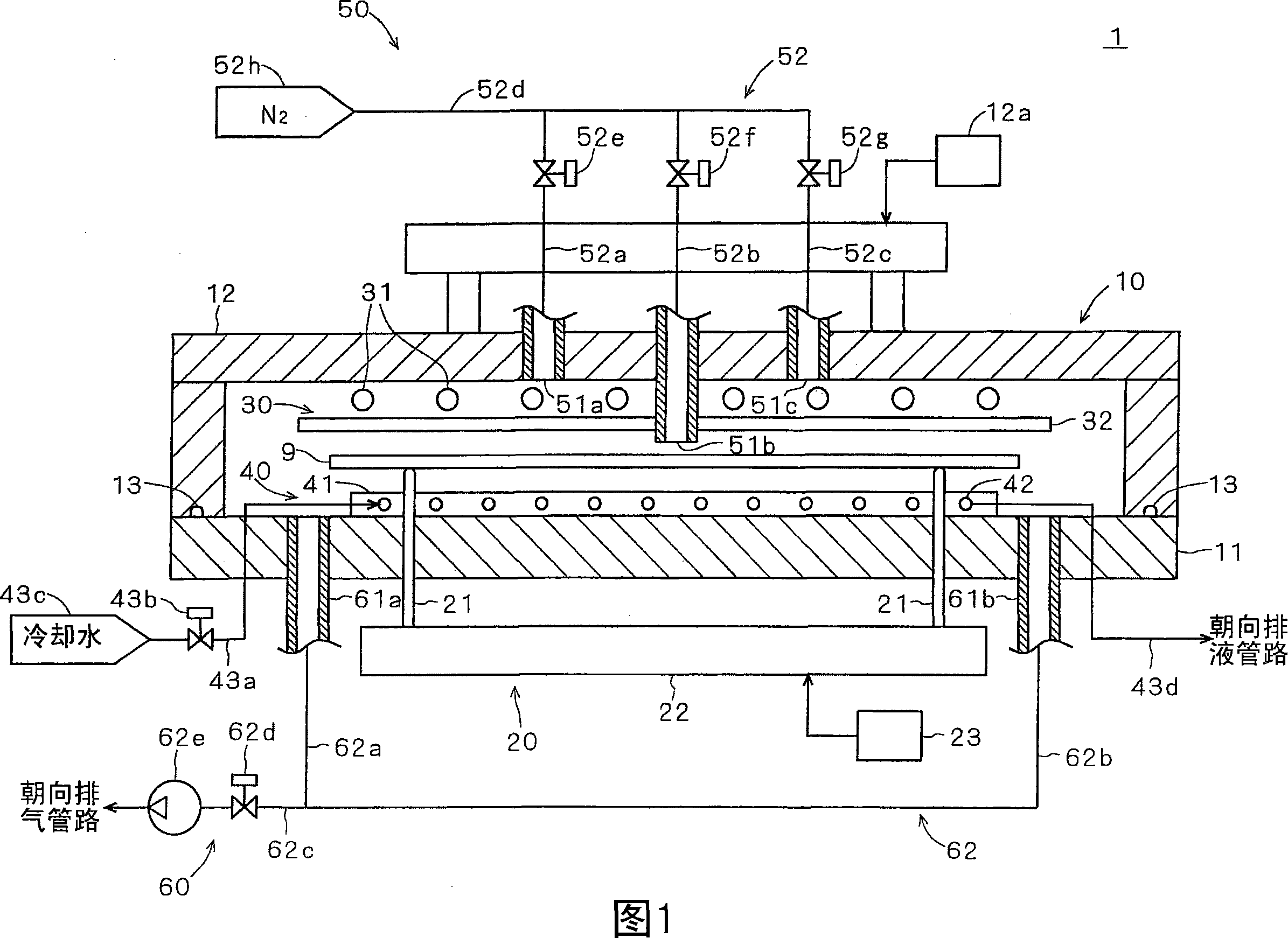

[0043] 1. The overall composition of the decompression drying device

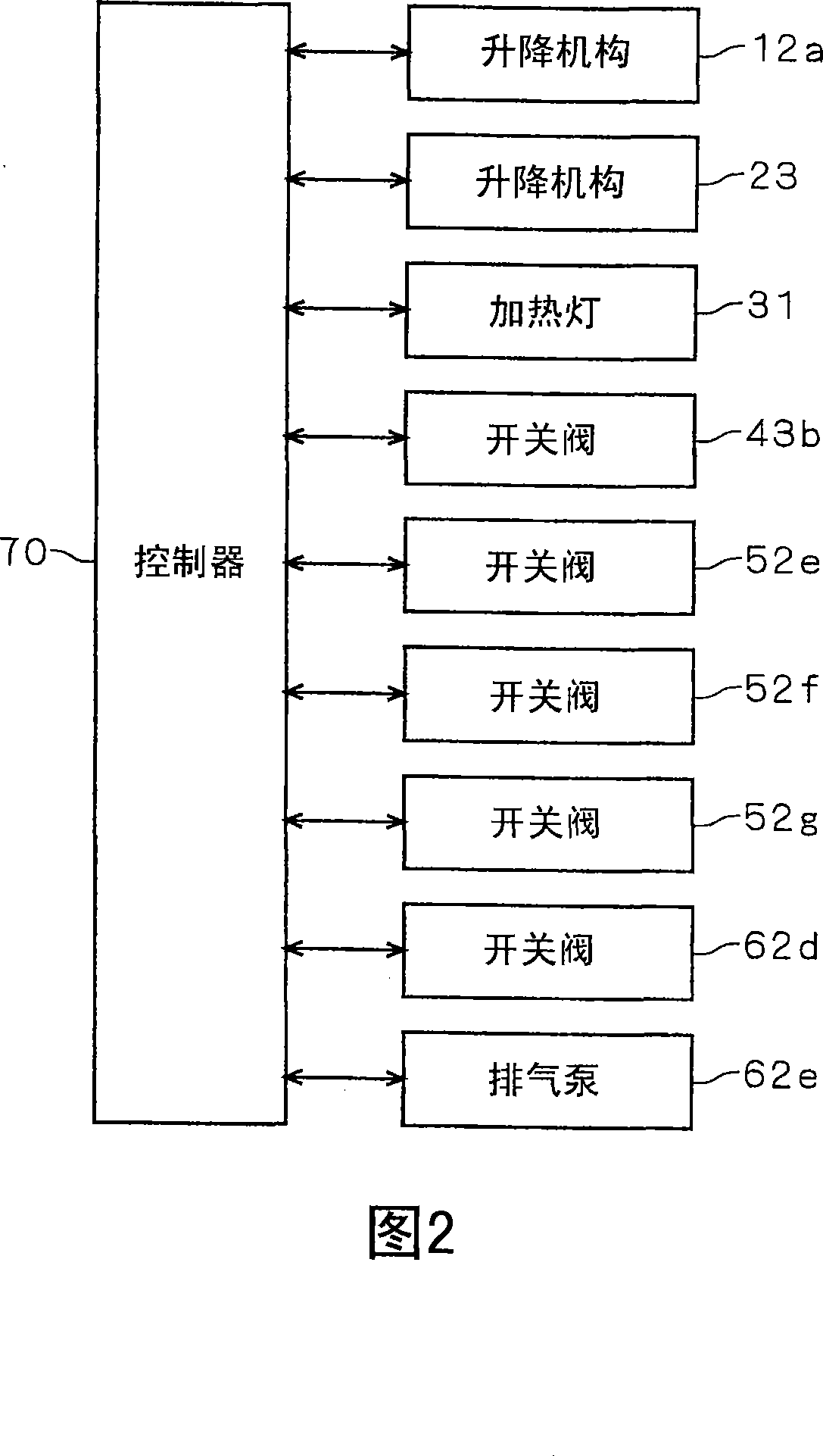

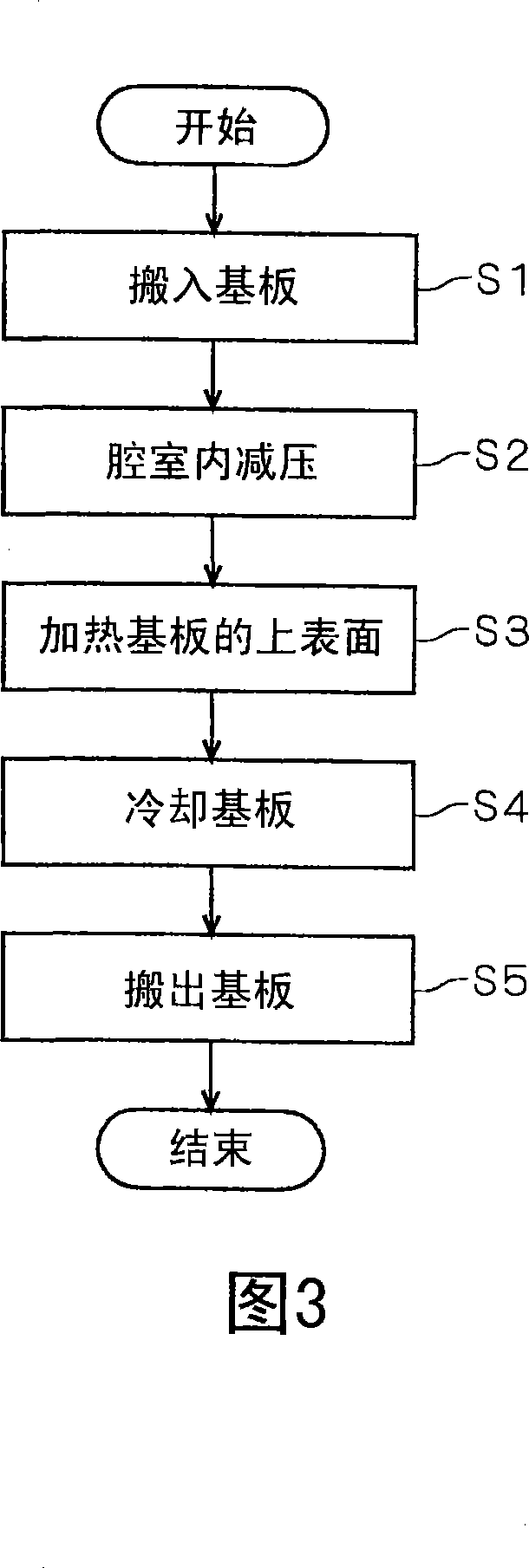

[0044] FIG. 1 is a longitudinal sectional view showing the configuration of a reduced-pressure drying apparatus 1 according to one embodiment of the present invention. FIG. 1 also schematically shows the configuration of the suction and exhaust system or drive system connected to the reduced-pressure drying device 1 . This reduced-pressure drying device 1 is used to selectively etch the surface of a rectangular glass substrate (hereinafter simply referred to as "substrate") 9 for liquid crystal display devices. Equipment for pressure drying and subsequent heating and cooling. As shown in FIG. 1 , the reduced-pressure drying apparatus 1 has a chamber 10 , a substrate holding unit 20 , a heating unit 30 , a cooling unit 40 , an air supply unit 50 , and an exhaust unit 60 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com