Project pile underwater concrete sampler and sampling method in construction

An underwater concrete and sampler technology, which is applied in mechanical depth measurement and other directions, can solve the problems of difficulty in accurately obtaining the depth of the concrete surface of engineering piles, affecting the smooth excavation of soil and stone in the basement, and increasing the cost of manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

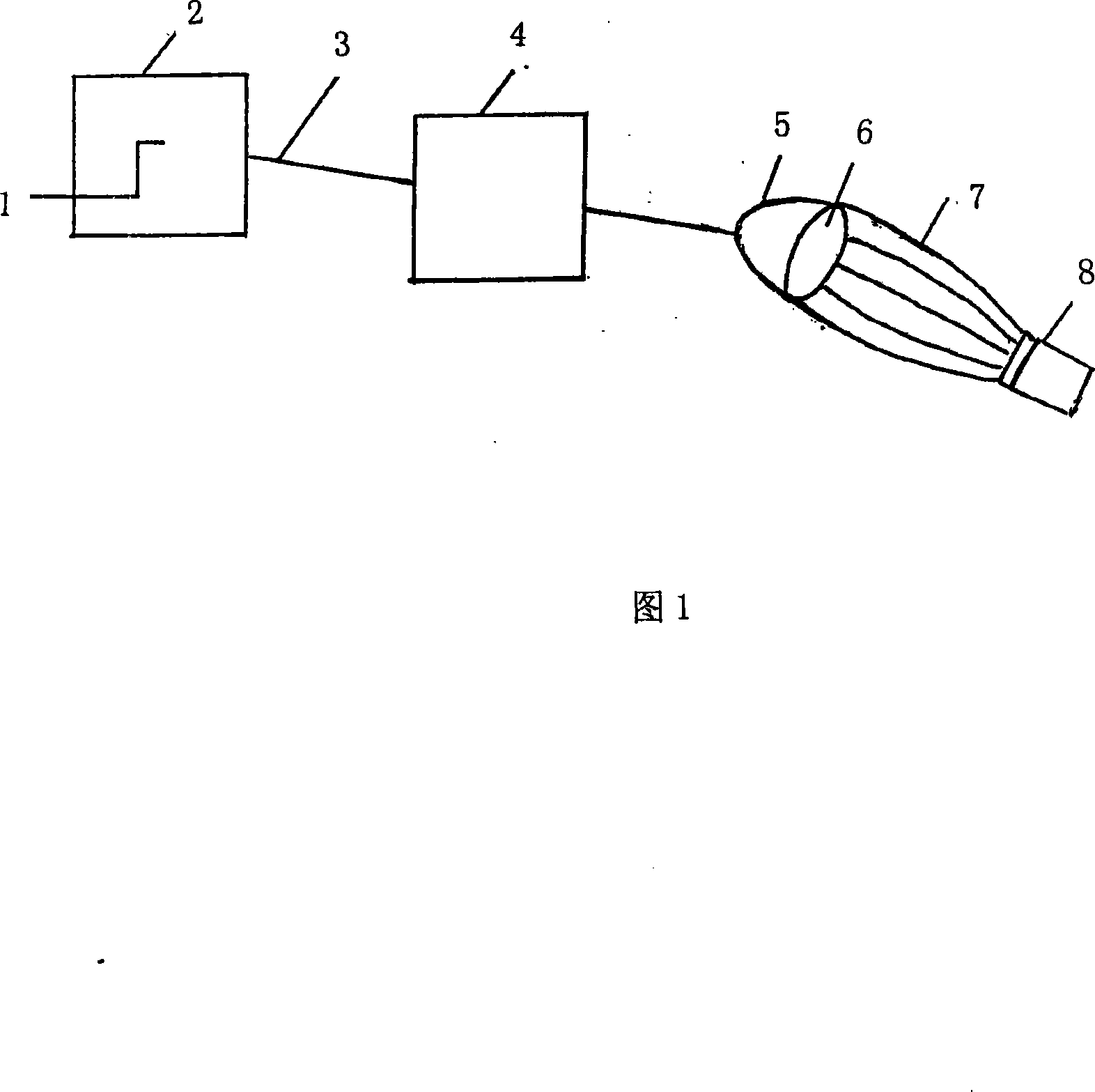

[0028] Embodiment 1 engineering pile underwater concrete sampler;

[0029] 1. a steel bar 7 with a diameter of 8mm is welded into an iron ring 6 with a diameter of 100mm, and on the iron ring 6, weld a suspension ring 5 made of a steel bar 7 with a diameter of 8mm, a height of 100mm, and an inverted "U" shape;

[0030] ②Take a piece of iron plate with a thickness of 3mm, cut a circular iron plate with a diameter of 50mm from the iron plate, weld an iron ring with a width of 30mm on the periphery of the circular iron plate, and the chassis 8 is completed;

[0031] ③Weld the upper ends of eight steel bars 7 with a diameter of 8 mm and a length of 350 mm to the iron ring 6, and the lower ends of the steel bars 7 extend into the iron ring of the chassis 8 and are welded on the iron ring of the chassis 8. The steel bars 7 are evenly spaced to form a waist drum Shaped iron cage, and ensure that there are gaps between the steel bars 7;

[0032] ④ Pull out the measuring rope 3 with a...

Embodiment 2

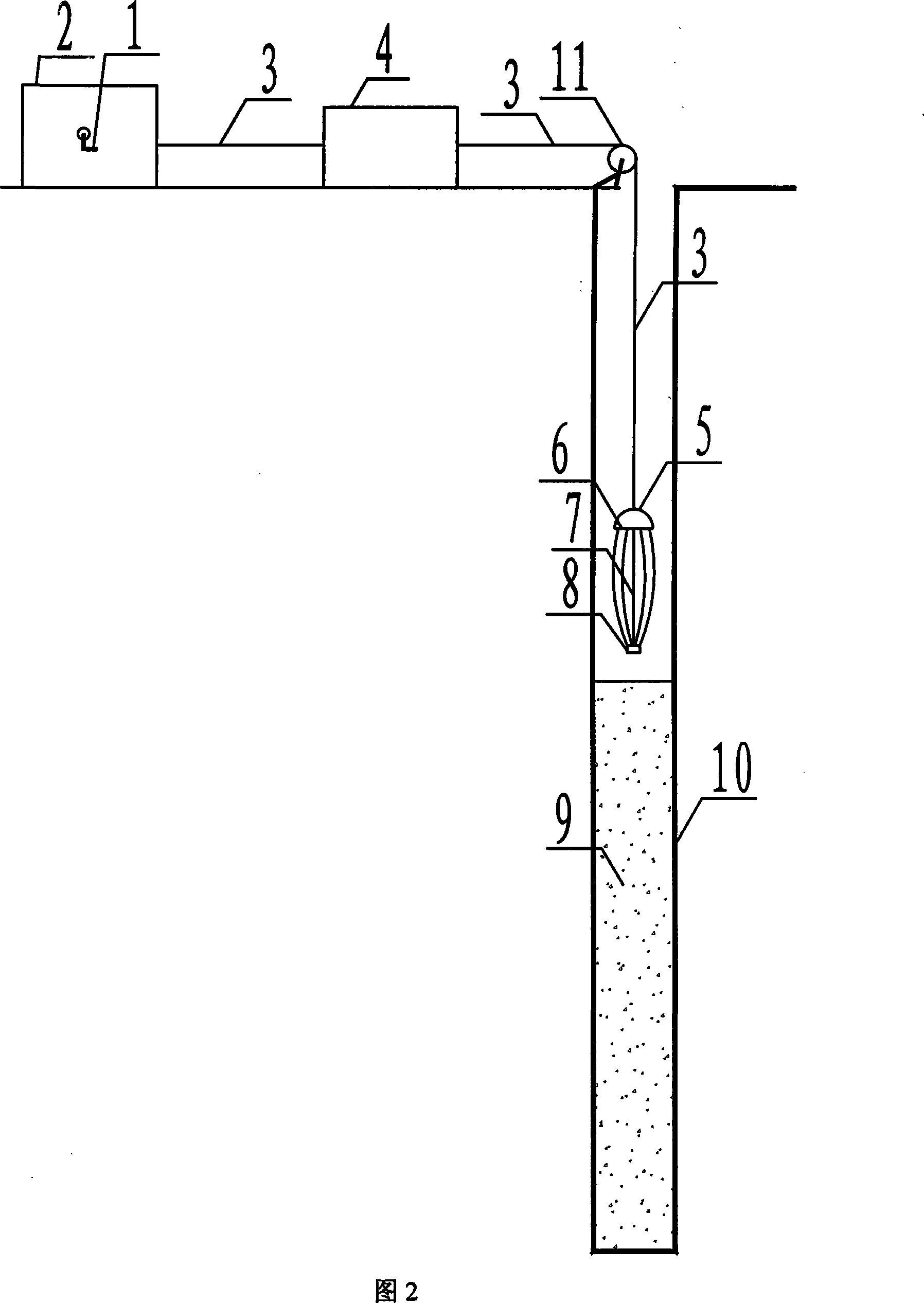

[0034] Embodiment 2——When the engineering pile pours concrete underwater, the sampling steps for judging the depth of the concrete surface by using the engineering pile underwater concrete sampler are as follows:

[0035] ① After the depth of borehole 10 has reached 27m, pour 15.7m into borehole 10 3 (V 理 = 1πr 2 =20×3.14×0.5 2 =15.7m 3 ) concrete 9;

[0036] ② Place the pulley 11 on the side of the drill hole 10, make the measuring rope 3 between the depth encoder 4 and the lifting ring 5 ride on the pulley 11, and place the welding ring 5, iron ring 6, steel bar 7 and chassis 8 At the hole 10, set the connection point between the suspension ring 5 and the measuring rope 3 as the zero point initial depth, and ensure that the zero point position is parallel to the ground;

[0037] ③Shake the hand crank 1, and lower the measuring rope 3 while observing the depth scale on the depth encoder 4 or measuring rope 3. When the connection point between the lifting ring 5 and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com