Thin membrane crystal cover packaging construction for preventing thin membrane dent forming glue filling bubble

A film-on-chip packaging and glue filling technology, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve problems such as the inability to fill the gap, the collapse of the circuit film 110, the expansion of the bonding area, and the generation of air bubbles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

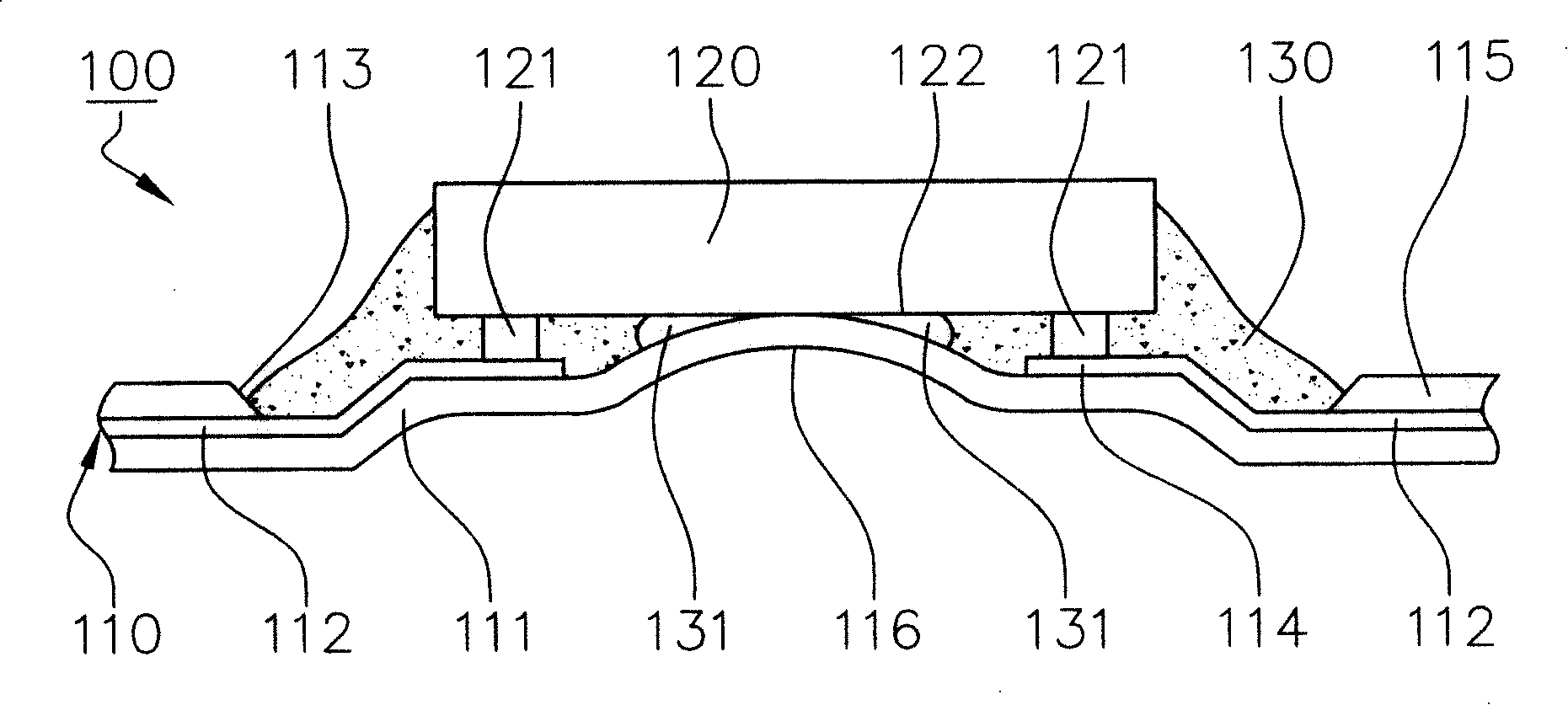

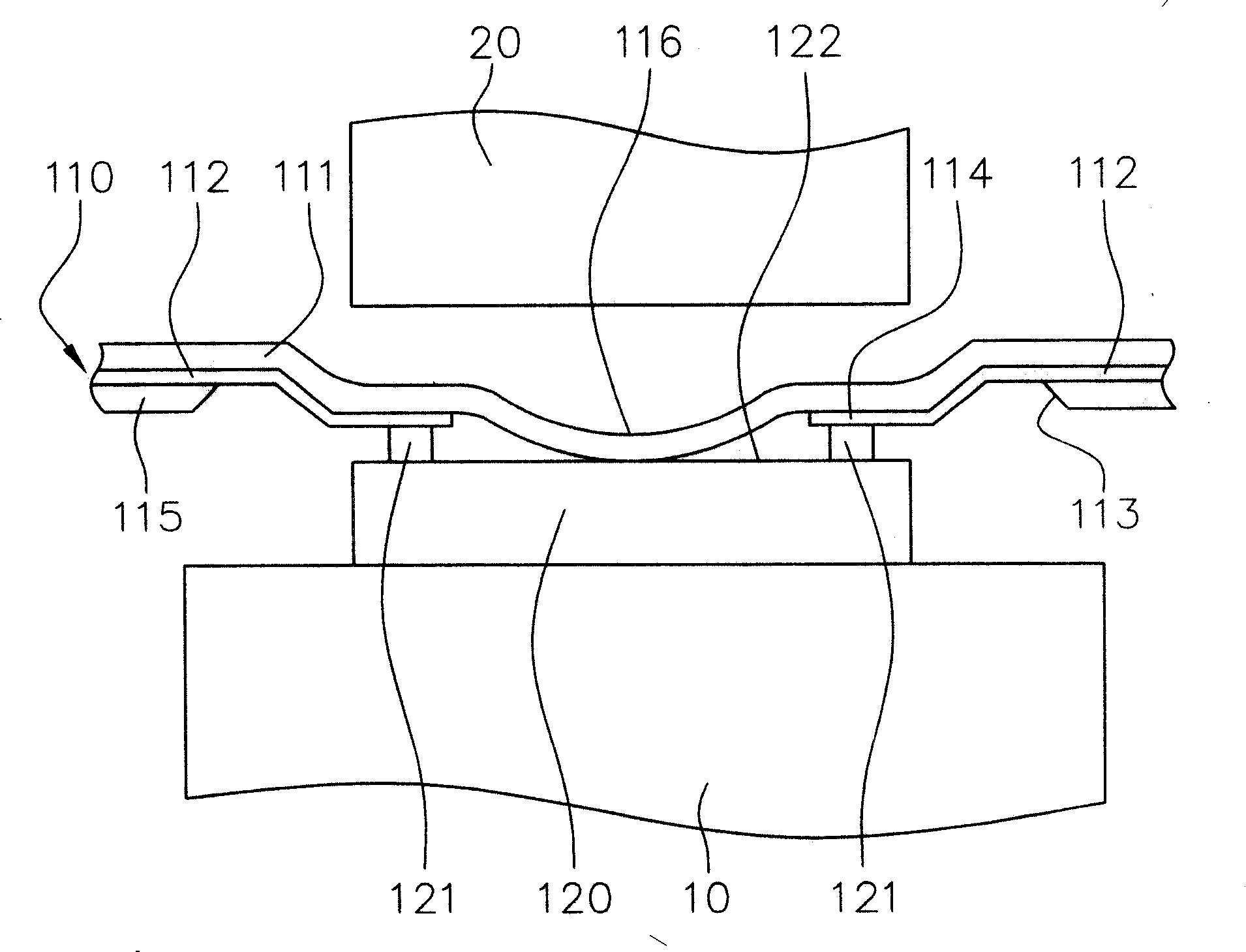

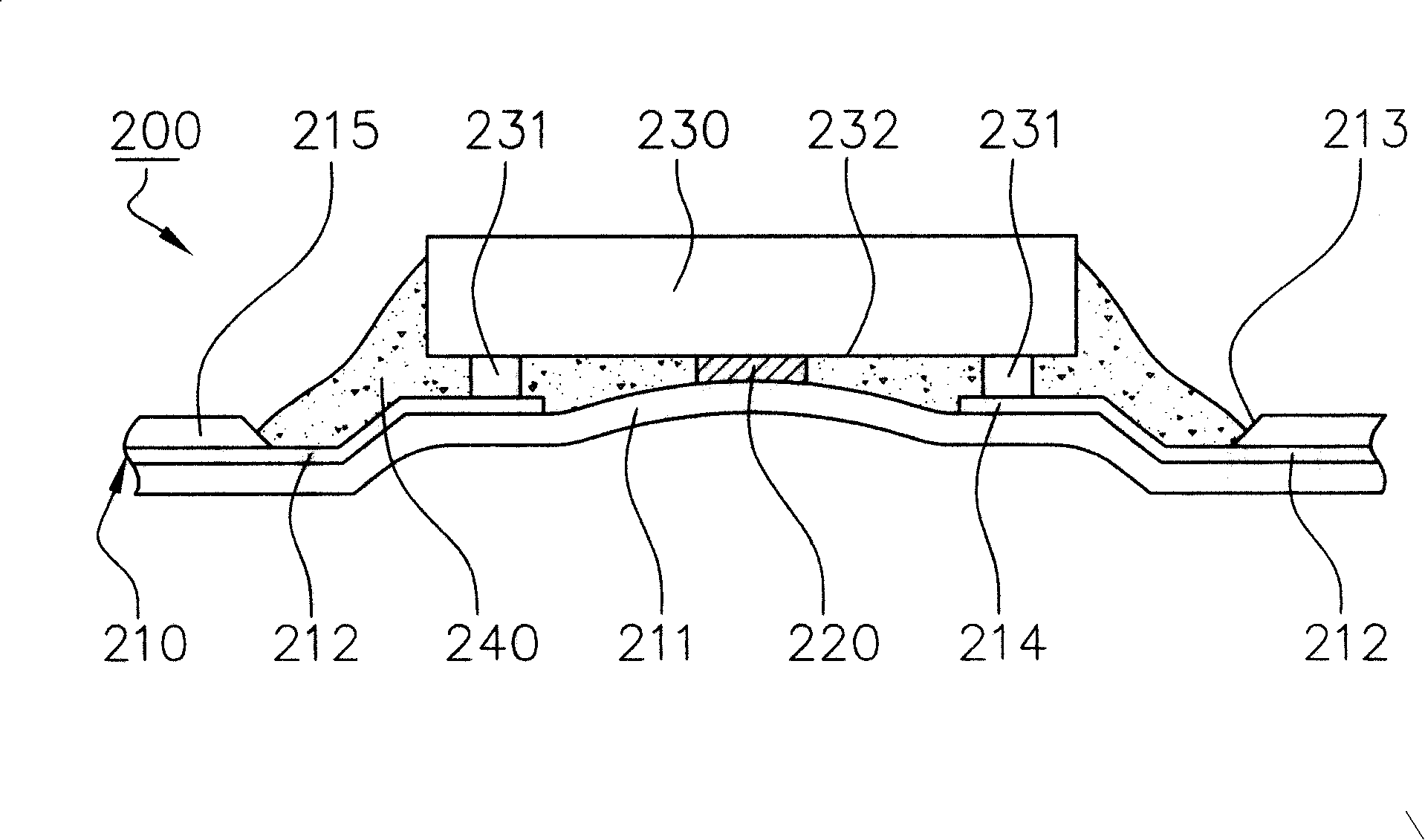

[0058] According to the first embodiment of the present invention, a thin film on chip package structure is disclosed that prevents the thin film from collapsing to form a filling bubble. Such as image 3 As shown, the chip-on-film package structure 200 mainly includes a circuit film 210, a plurality of non-conductor spacers 220, a chip 230, and a dot glue 240. In this embodiment, the non-conductor spacers 220 are first arranged on the circuit film 210 (e.g. Figure 5 Shown).

[0059] Such as image 3 and Figure 4 As shown, the circuit film 210 mainly has a soft dielectric layer 211 and a plurality of pins 212. A wafer bonding area 213 is defined on a surface of the circuit film 210 as a coverage area for bonding the wafer 230. The circuit film 210 may further include a solder resist layer 215 formed on the soft dielectric layer 211 to cover a part of the pins 212. In this embodiment, the chip bonding area 213 is defined by the opening of the solder mask 215.

[0060] Generally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com