Method for manufacturing printed circuit board with built-in capacitor

A technology of printed wiring board and manufacturing method, which is applied in the direction of printed circuit manufacturing, capacitors, fixed capacitors, etc., can solve the problems of difficulty in component manufacturing and installation, the need for component cost and installation cost, and the inability to make small capacitance capacitors and large capacitance capacitors, etc., to achieve The effect of preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the present invention will be further described with reference to the illustrated embodiments.

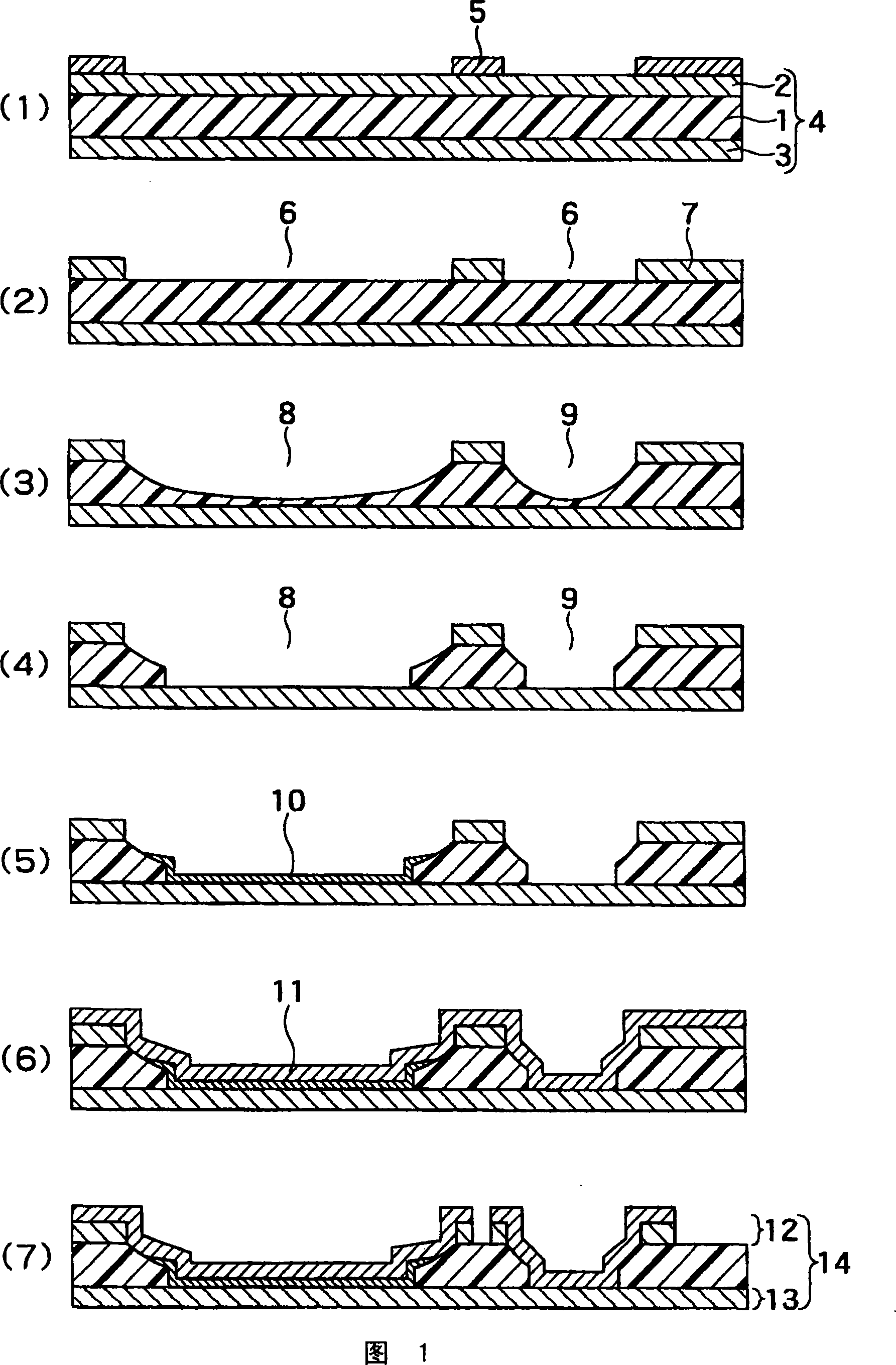

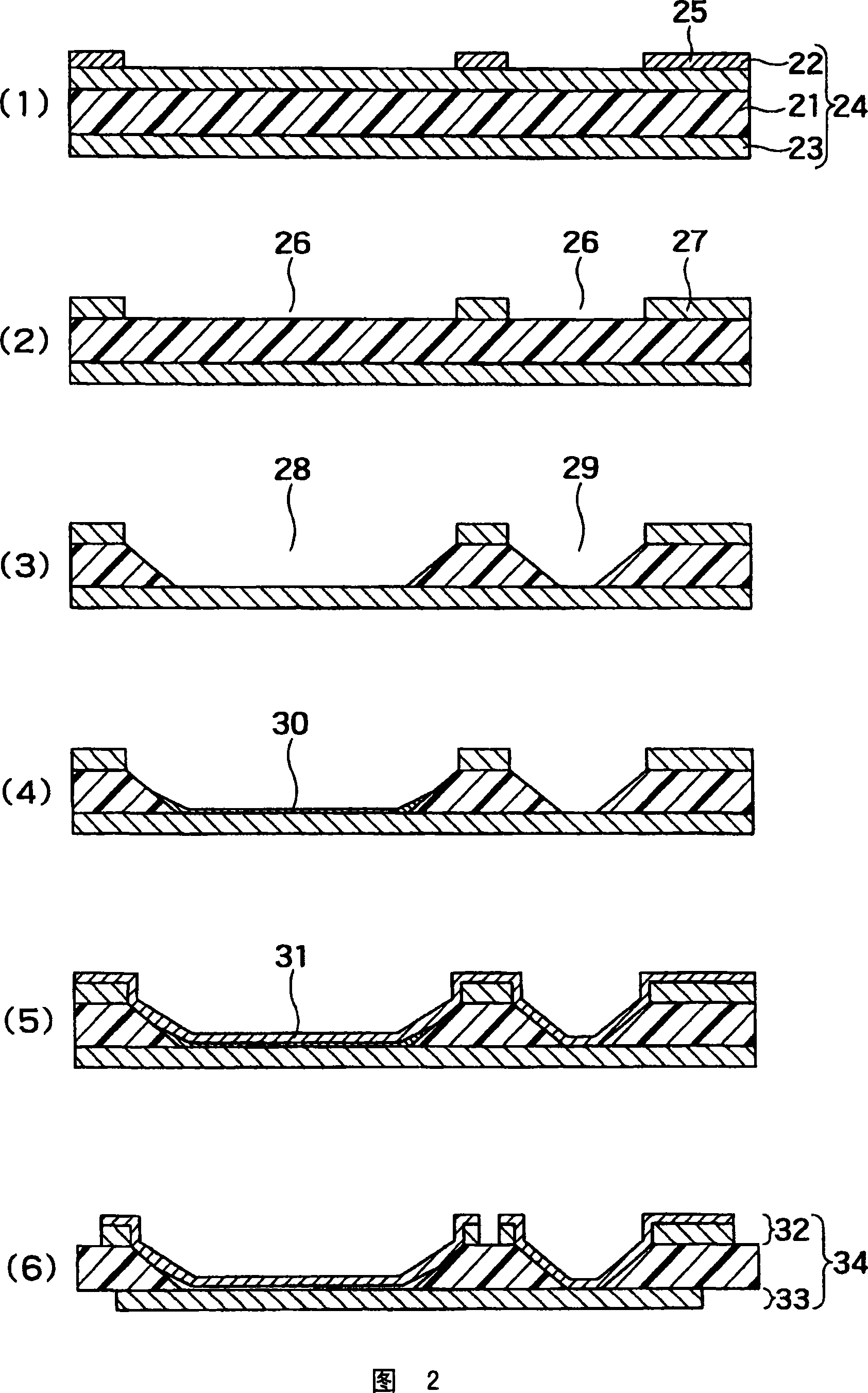

[0039] FIG. 1 is a cross-sectional view showing a method of manufacturing a printed wiring board incorporating a capacitor structure according to an embodiment of the present invention. In this method, first, as shown in FIG. 1(1), a so-called flexible insulating base material 1 having a first metal foil 2 such as copper foil and a second metal foil 3 on both sides of a flexible insulating base material 1 such as polyimide is prepared. For the double-sided copper-clad laminate 4, a resist layer 5 is formed on the desired position of the first metal foil 2 by using an etching method using a usual photochemical etching manufacturing method. The portion where the hole is formed has a metal mask with an opening.

[0040] In this step, it is preferable to stick a dry film resist or the like using a laminator or the like. Also, 25 μm thick polyimide was used as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com