Method for knitting degradable heart atrial septal defect plugging device

A technology of atrial septal defect and occluder, which is applied in the field of medical devices and can solve problems such as the lack of preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

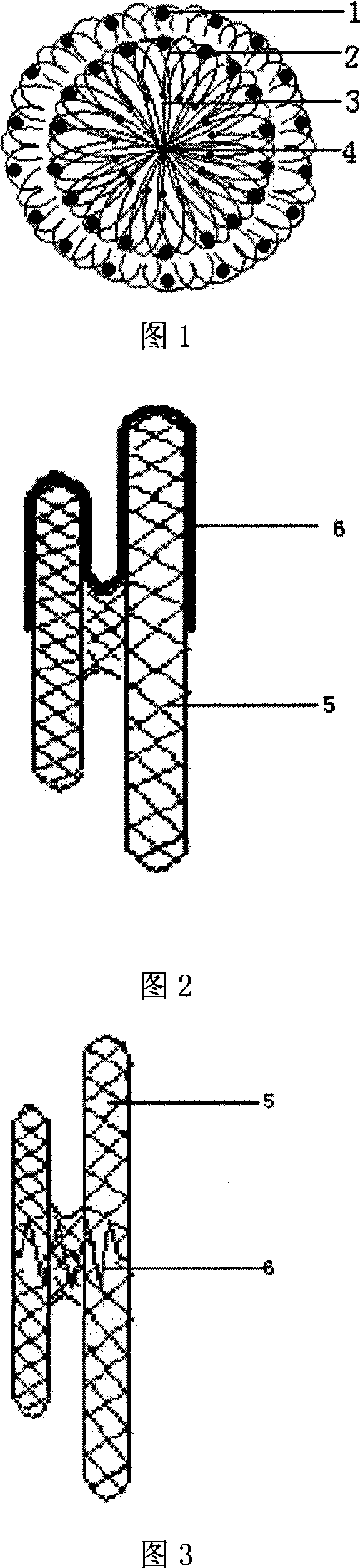

[0037] Take 36 PLLA (poly-L-lactic acid) monofilaments and weave the occluder according to the planar method. First, a mold with three rings of steel needles is made on a plane, and then the PLLA monofilament is folded and wound, braided and shaped, and then heat-set. After 4 weeks of storage, the shape remained intact, and the resilience and clamping force met the requirements.

[0038] Further animal experiments were used to implant the shaped occluder woven by this method into the body of experimental dogs, and it was found that the degradable occluder could maintain its clamping force for a long time without falling off. It shows that the occluder obtained by this planar weaving method can replace the metal occluder.

Embodiment 2

[0040]Take 36 PBO (polyphenylene benzobisoxazole) monofilaments and weave them into a double umbrella occluder according to the planar method. Firstly, a mold with three rings of steel needles is made on the plane, and then the PBO monofilaments are folded back Winding, weaving and forming, then adding 4 alloy wires on the surface according to the method shown in Figure 2, and finally heat setting. After the production is completed, the occluder is introduced into the body of the experimental dog through the delivery device for animal experiments.

[0041] During the experiment, the growth of the dog was good, and no complications occurred. This kind of occluder is firmly clamped on the defect site and will not fall off easily.

[0042] After 30 days, the animals were observed under a scanning electron microscope, and it can be found that the PBO part of the occluder stent has been degraded to a considerable extent in the SEM photos. After 6 months, the PBO monofilament part...

Embodiment 3

[0044] Take 36 polycaprolactone monofilaments, first make a mold with three rings of steel needles on the plane, then make the polycaprolactone monofilaments turn back and wind, braid and shape, and then heat-set. After 4 weeks of storage, the shape remained intact, and the resilience and clamping force met the requirements.

[0045] Further animal experiments were used to implant the shaped occluder woven by this method into the body of experimental dogs, and it was found that the degradable occluder could maintain its clamping force for a long time without falling off. It shows that the occluder obtained by this planar weaving method can replace the metal occluder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com