Method for reclaiming nickel and chromium from stainless steel sludge

A recycling method, stainless steel technology, applied in the field of resource recycling in the environmental protection industry, can solve problems such as inability to treat environmental problems, secondary pollution, huge economic costs, etc., and achieve the effects of solving pollution problems, simple process methods, and universal industrial raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

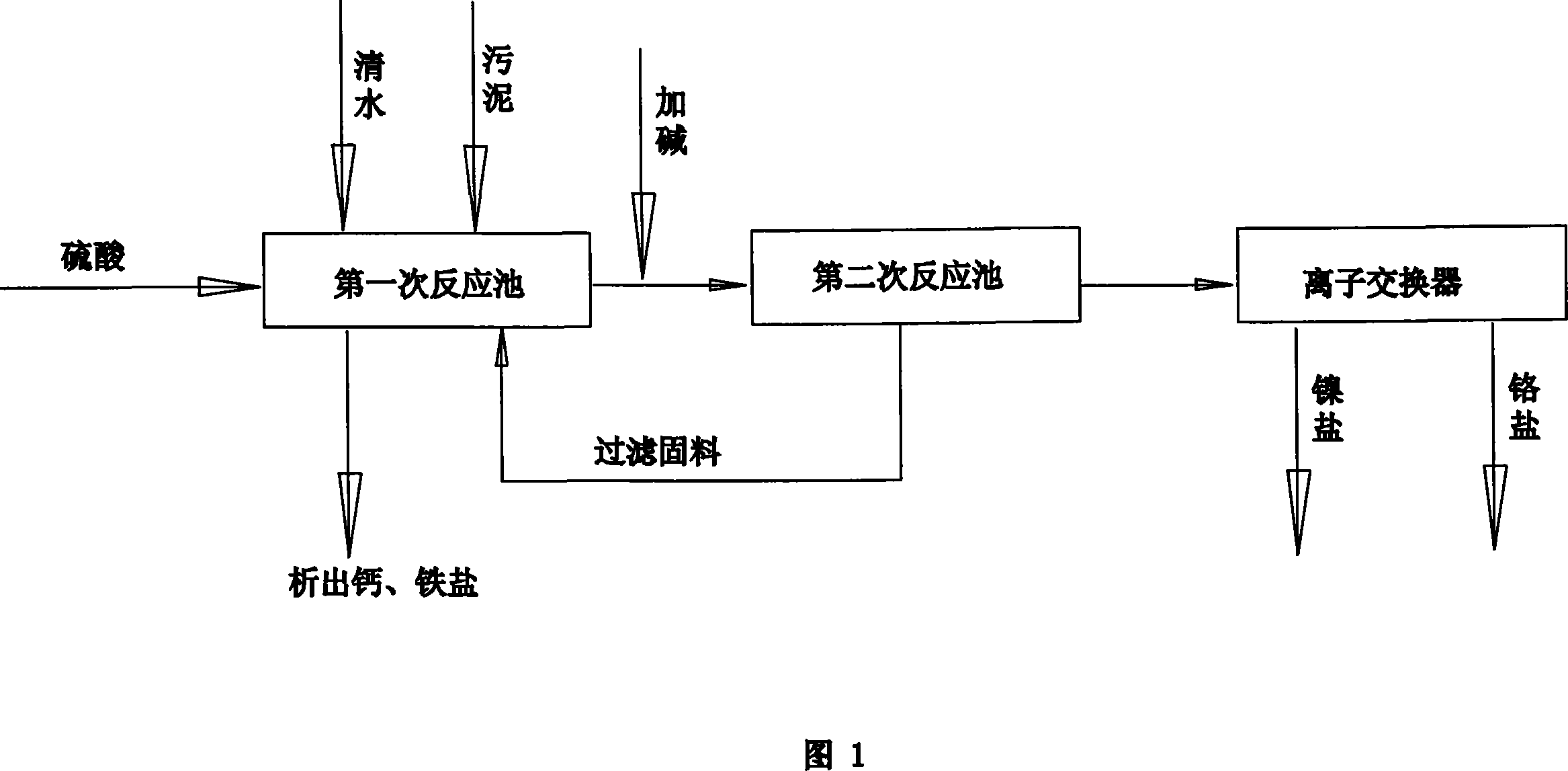

Embodiment 1

[0026] Take 100g of stainless steel waste water sludge, place it in the first reaction tank, add 400g of clear water, and then add 12g of concentrated sulfuric acid to obtain a pH value of 2.0, filter after full reaction, remove the filter cake, and send 401g of the clear liquid to the second In two reaction tanks, add caustic soda 23g in the second reaction tank, the available pH value is 6.1, fully reacts. The reactants are then filtered, and the resulting filter cake is sent to the first reaction tank for recycling with the newly added sludge. Clear liquid is sent to ion exchange device again, carry out ion exchange, can obtain the solution 14g that contains nickel sulfate and the liquid 3g that contains chromium sulfate, through measuring: wherein the concentration of the solution that contains nickel sulfate is 60g / L, and the solution that contains chromium sulfate The concentration of the solution is 80g / L. The filtered solids in the accompanying drawings are the filter...

Embodiment 2

[0028] Operate in the manner of Example 1, place 100g of stainless steel wastewater sludge of different batches in the first reaction tank, add 400g of clear water, and then add 13g of concentrated sulfuric acid to obtain a pH value of 1.9, and filter after fully reacting , Remove the filter cake, send clear liquid 400g in the second reaction pool, add caustic soda 21g in the second reaction pool, the available pH value is 5.2, carry out sufficient reaction. The reactants are then filtered, and the resulting filter cake is sent to the first reaction tank for recycling with the newly added sludge. Clear liquid is sent to ion exchange device again, carries out ion exchange, can obtain the solution 16g that contains nickel sulfate and the liquid 4g that contains chromium sulfate, through measuring: wherein the concentration of the solution that contains nickel sulfate is 61g / L, and the solution that contains chromium sulfate The concentration of the solution was 82g / L.

Embodiment 3

[0030] Operate in the manner of Example 1, place 100g of stainless steel wastewater sludge of different batches in the first reaction tank, add 400g of clear water, and then add 11g of concentrated sulfuric acid to obtain a pH value of 2.7, and filter after fully reacting , Remove the filter cake, send clear liquid 403g in the second reaction tank, add caustic soda 20g in the second reaction tank, the available pH value is 4.8, fully react. The reactants are then filtered, and the resulting filter cake is sent to the first reaction tank for recycling with the newly added sludge. Clear liquid is sent to ion exchange device again, carry out ion exchange, can obtain the solution 18g that contains nickel sulfate and the liquid 5g that contains chromium sulfate, through measuring: wherein the concentration of the solution that contains nickel sulfate is 56g / L, and the solution that contains chromium sulfate The concentration of the solution was 74g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com