Pure quartz core cladding mode resonant special type optical fibre and method for making same

A special optical fiber and quartz technology, applied in the field of pure quartz core cladding mode resonant special optical fiber, can solve the problems of complex preparation process and performance degradation, and achieve the effects of mature preparation process, good performance consistency and optimization of structural parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

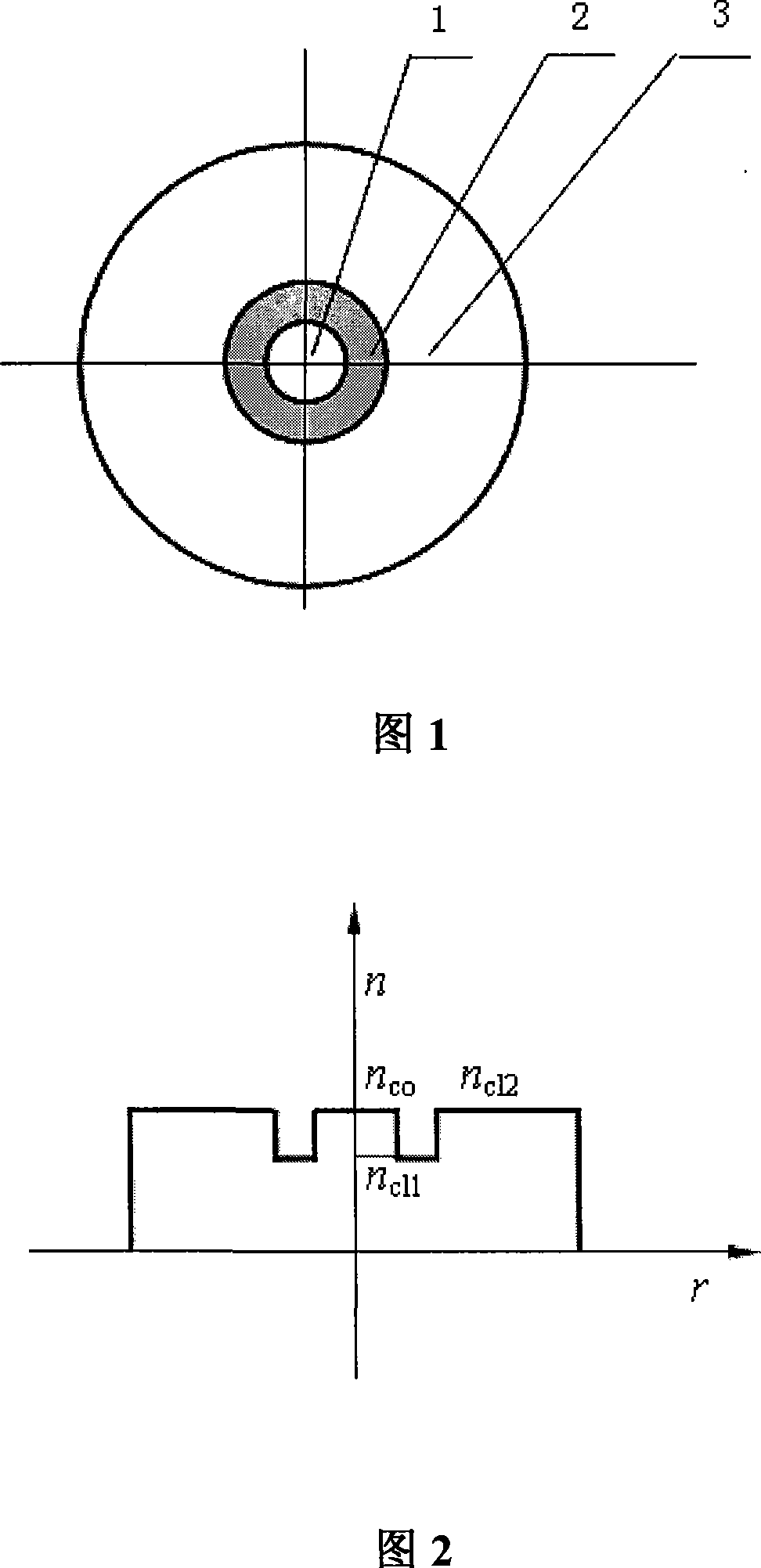

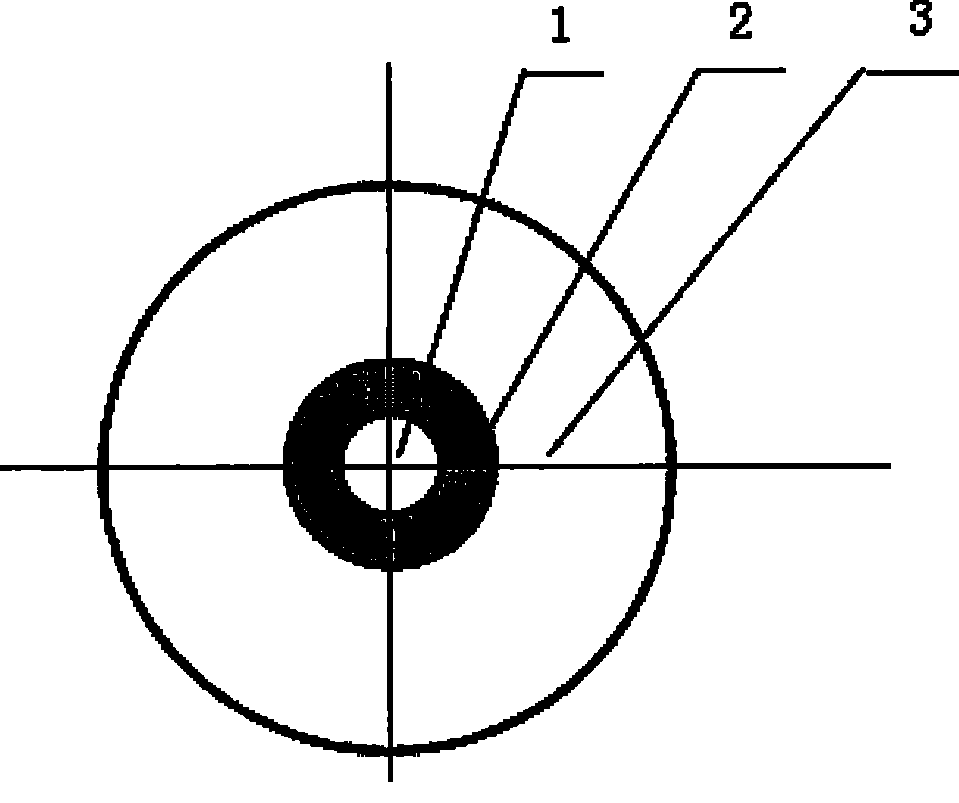

[0018] Embodiment one: see figure 1 , a pure silica core-cladding mode resonant special optical fiber of the present invention consists of three parts: core 1, resonant inner cladding 2 and outer cladding 3. The material of the core 1 is pure quartz, the material of the resonant inner cladding 2 is composed of pure quartz doped with low refractive index fluorine F, and the material of the outer cladding 3 is pure quartz. The resonant inner cladding 2 is sandwiched between the core 1 and the outer cladding 3 .

[0019] The above-mentioned pure silica core-cladding mode resonant special optical fiber, the core (1) is a high-purity quartz material, and the resonant inner cladding (2) is pure silica as a matrix doped with 450ppm fluorine. For a 125μm single-mode optical fiber, the cladding The thickness is 15μm.

[0020] The preparation method of the above-mentioned pure quartz core-cladding mode resonant special optical fiber is to use the gas phase deposition method MCVD to di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com