Assemble timber

An assembled, wood technology, used in wood processing appliances, wood veneer joining, manufacturing tools, etc., can solve the problems of cracking, internal cracking, warping deformation and gluing, and reduce internal stress and warping deformation. The effect of increasing and drying moisture content is consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

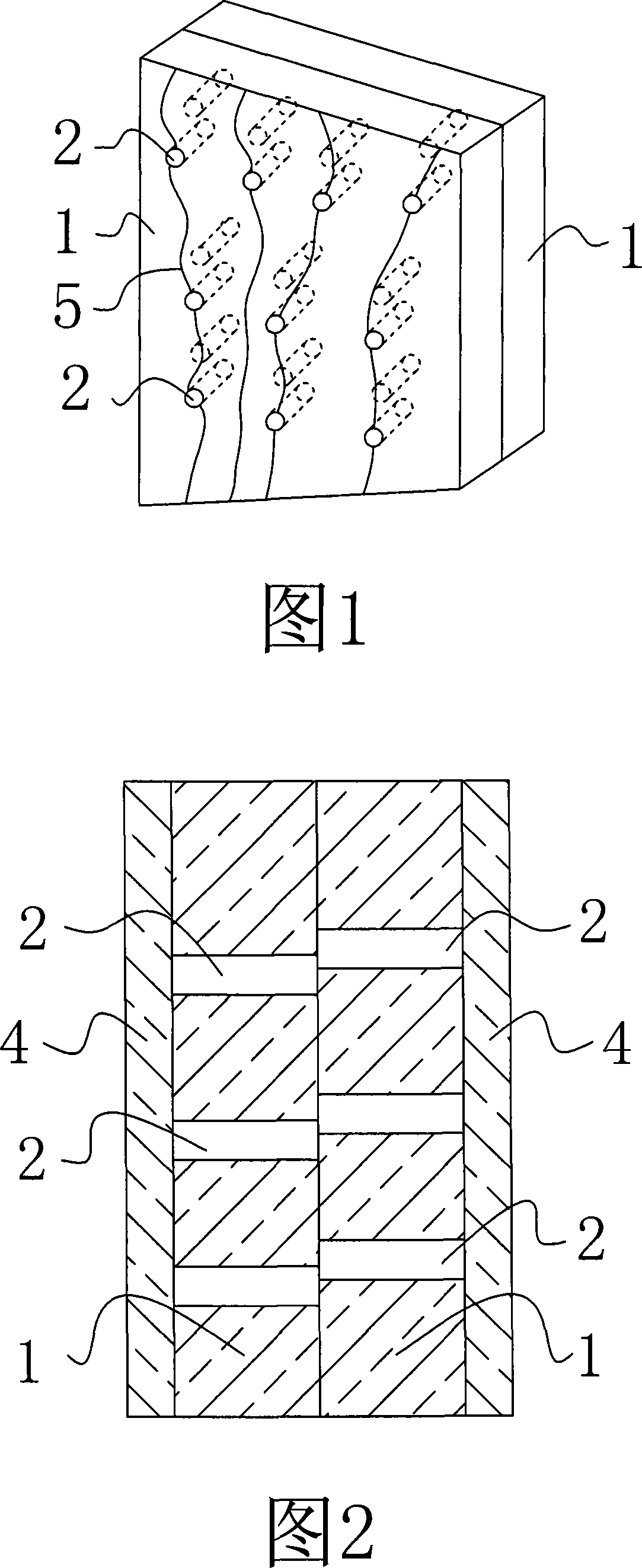

[0024] As shown in Figure 1, it is the assembling structure diagram of the timber board of the present embodiment. Two timber boards 1 can be seen as shown in the figure.

[0025] As shown in Figure 2, it is a longitudinal sectional view of this embodiment. An assembled timber, comprising a timber board 1 . In this technical solution, there are two wood boards 1, and the wood board 1 is provided with a plurality of holes 2, such as being provided with a plurality of holes 2 on the front or side of the cross-section of the wood board 1 according to processing requirements, such as setting There are 10 holes 2, of course, the number of holes 2 of the wood board 1 can be determined as one or more according to the wood material and product requirements, and the depth of the holes 2 can be determined to be pierced or not according to the wood material and product requirements For example, in this embodiment, hole 2 belongs to the case of piercing, and the position of hole 2 can b...

Embodiment 2

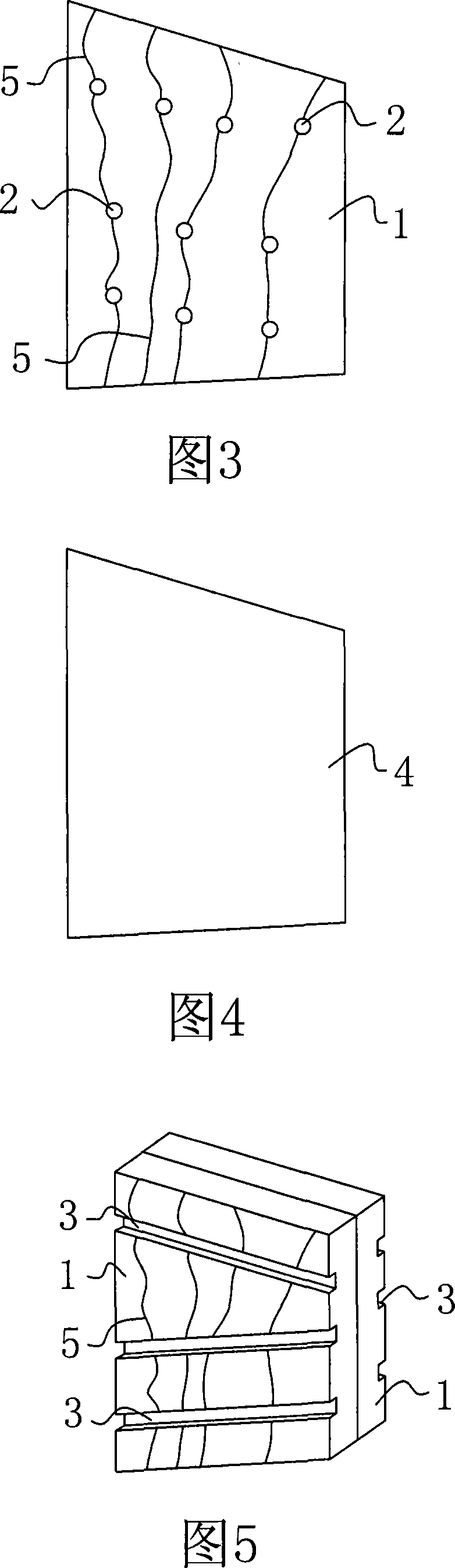

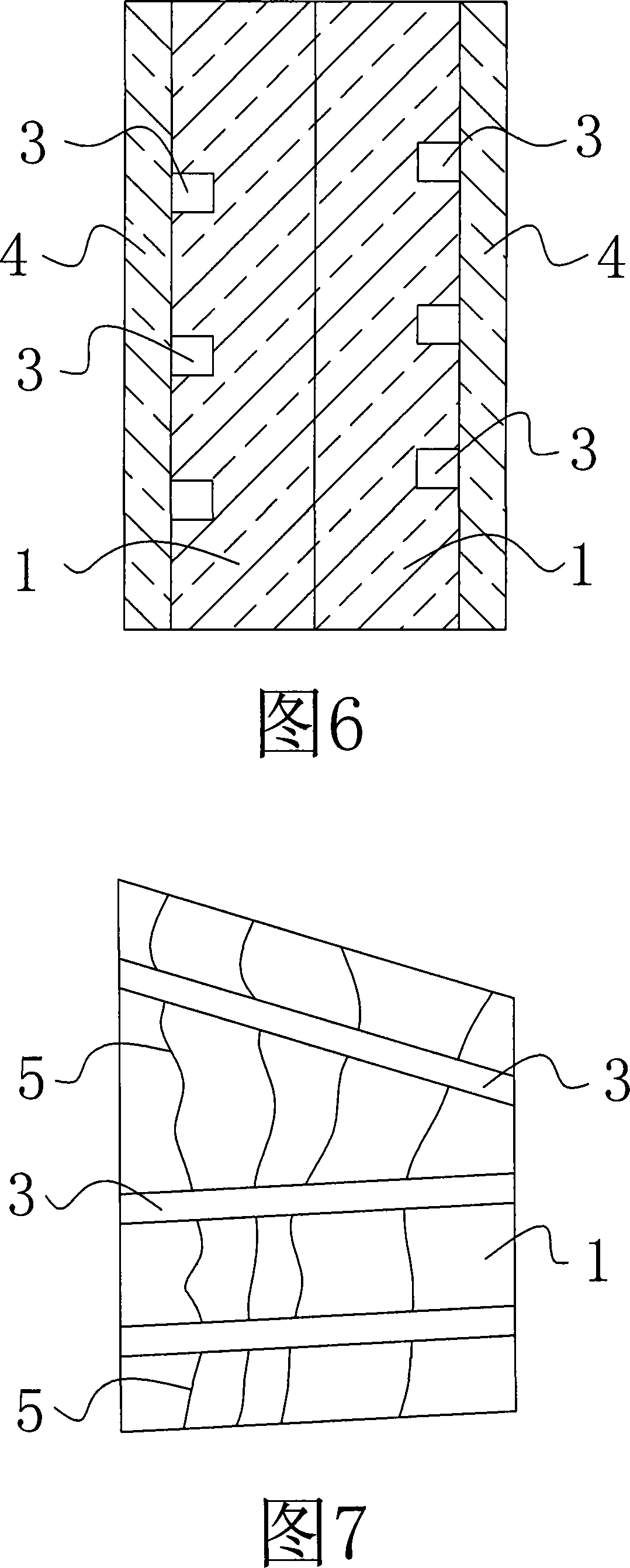

[0030] As shown in Fig. 5, it is the wood panel installation structure diagram of the present embodiment. Two timber boards 1 can be seen as shown in the figure.

[0031] As shown in FIG. 6, it is a longitudinal sectional view of this embodiment. An assembled timber, comprising a timber board 1 . In this technical solution, there are two wood boards 1, and the front or side of the cross-section of the wood board 1 is provided with a plurality of grooves 3 according to processing needs, such as three grooves 3, of course, the groove 3 of the wood board 1 The quantity can be determined as one or more according to the timber material and product requirements, and the depth of the groove 3 can be determined according to the timber material and product requirements to be pierced or not pierced and the depth without piercing, for example, in this In the embodiment, the groove 3 belongs to the situation of piercing, but it can also be the case that the depth of the groove 3 is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com