Transport device in a facility for processing substrates

A technology for transporting devices and processing substrates, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as interference sources, and achieve high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

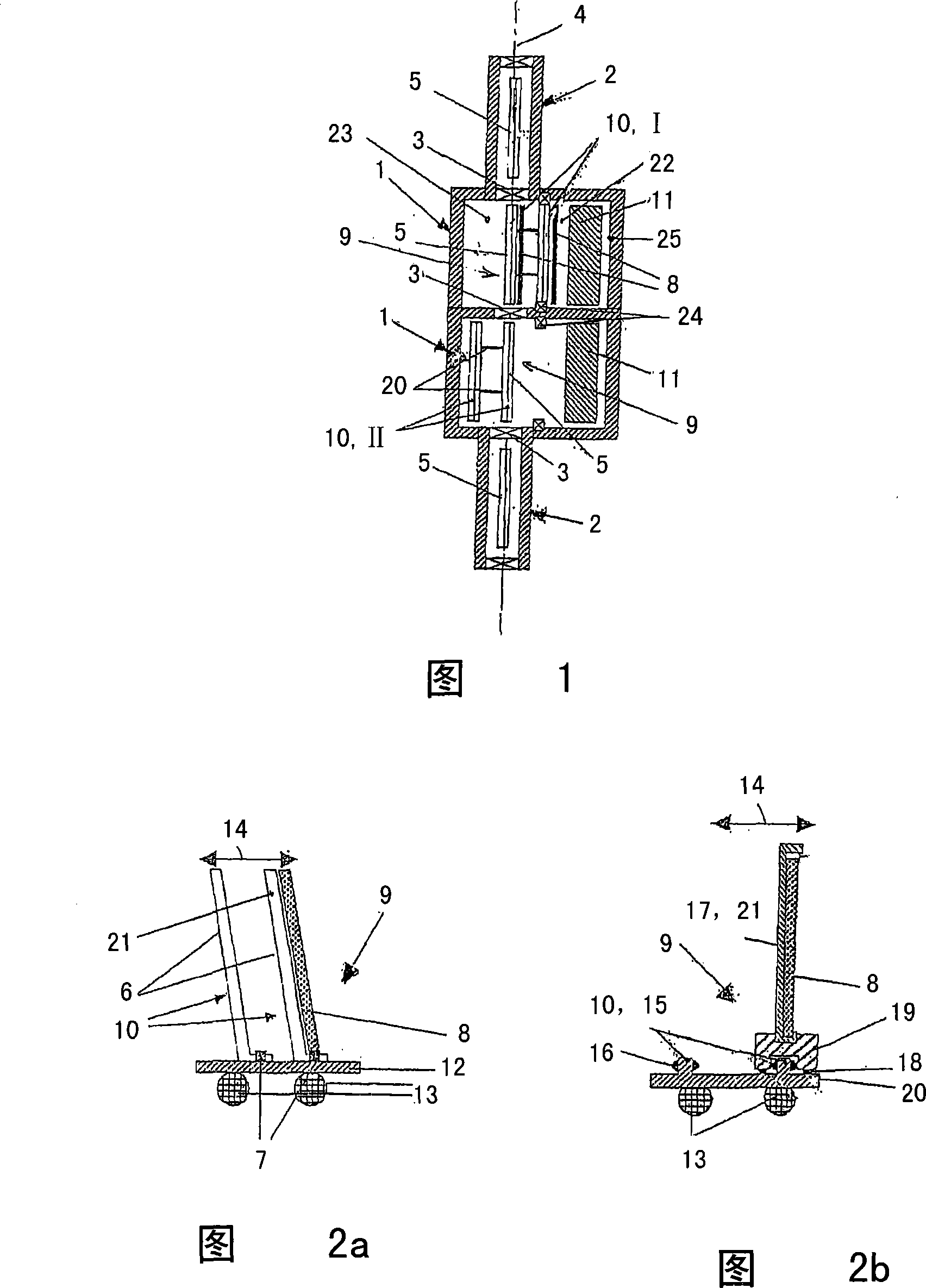

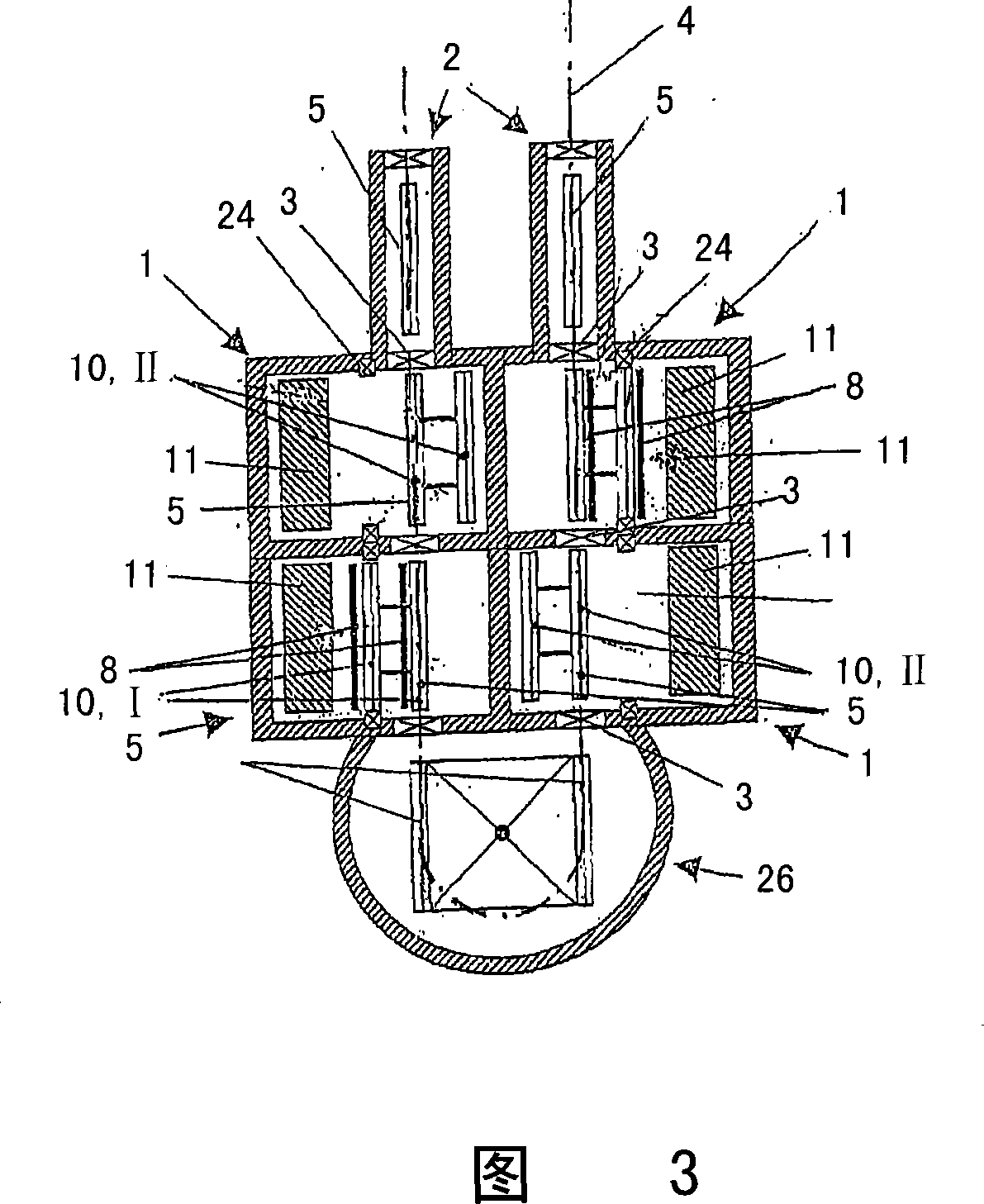

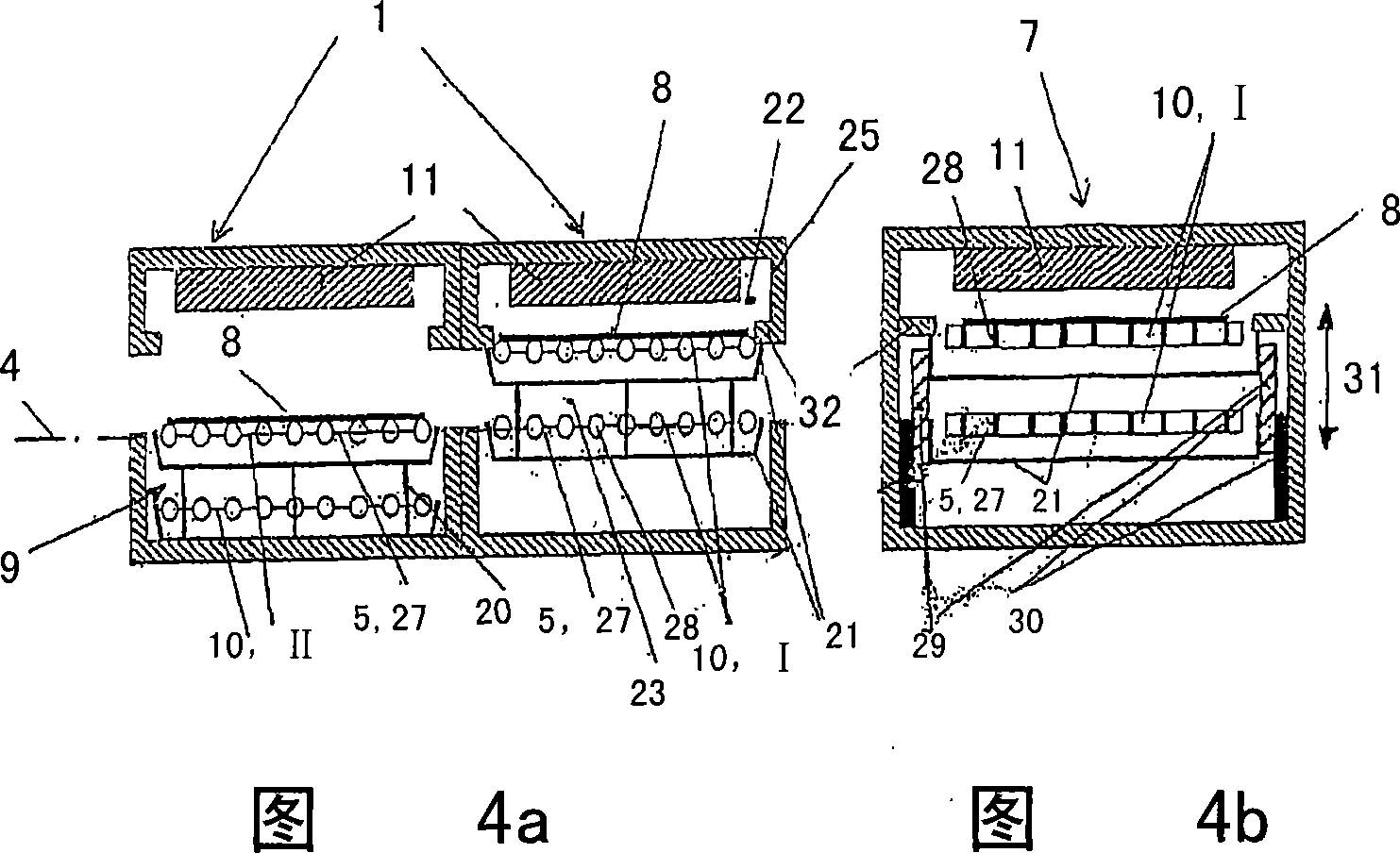

[0057] In FIG. 1, the vertical in-line coating apparatus according to embodiment A comprises two adjacent coating stations 1 and two adjacent lock chambers 2, wherein the coating stations 1 and the lock chambers 2 are controlled by a vacuum-tight chamber valve 3 to separate from each other. The transport device according to the invention passes through the lock chamber 2 and the coating station 1 , said device being formed by several transport segments 5 arranged in succession along the transport line 4 . The transport sections 5 according to embodiment A are formed for transporting substantially vertically aligned flat substrates 8, wherein, in particular, the transport sections 5 in FIG. Or substantially vertically oriented substrate guide plate 6, and transport rollers 7 are arranged at the base (can be easily seen from Fig. 2a), by means of transport rollers 7, a flat substrate 8 can stand slightly inclined along The transport line 4 transports through the in-line coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com