Gold electroforming technique

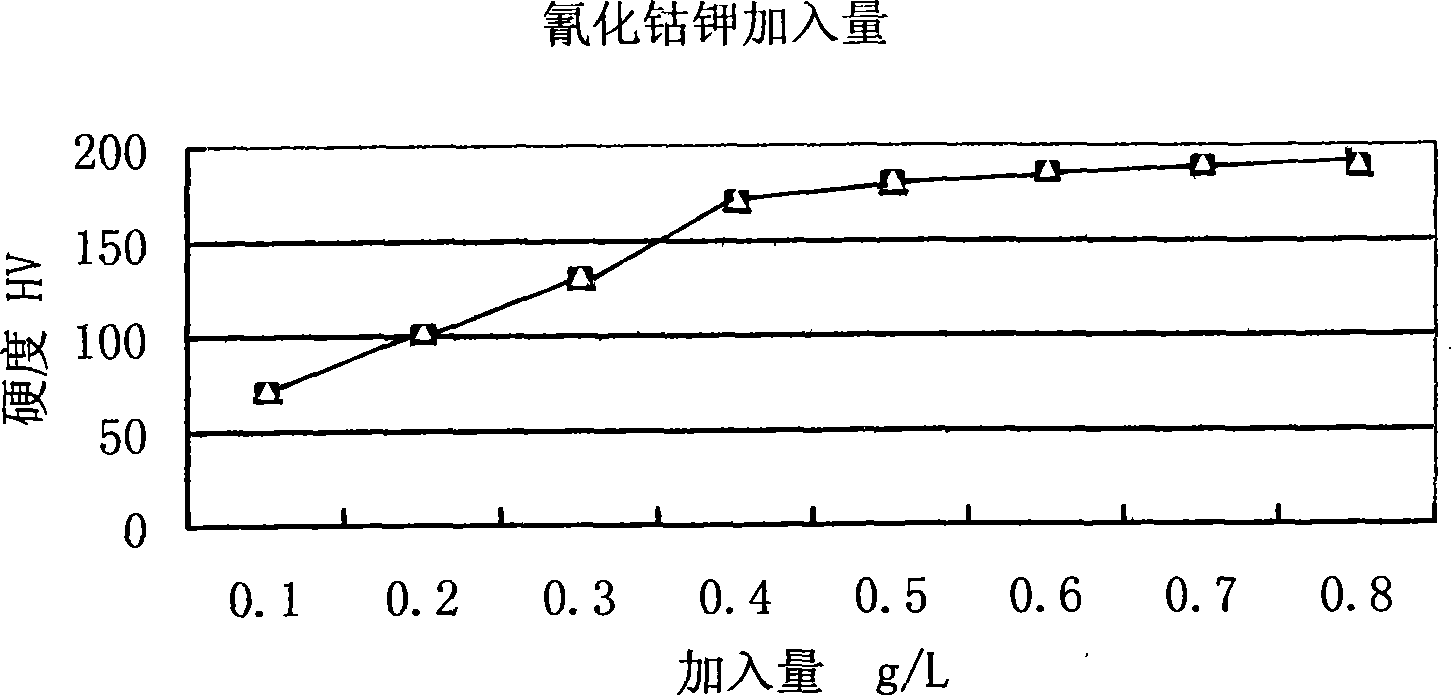

A technology of electroforming and gold, which is applied in the direction of electroforming and electrolysis, can solve the problems of low hardness and low yield, and achieve the effects of increased hardness, uniform and dense grains, and reduced impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

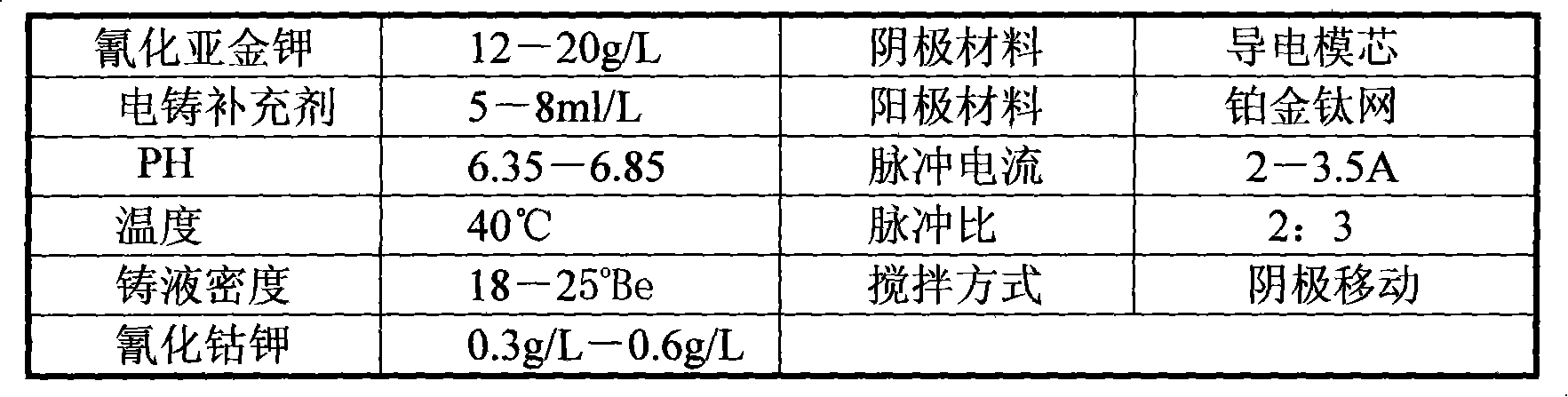

[0020] A process for electroforming gold, comprising the following steps;

[0021] A. Add 2 / 3 of the total volume of deionized water into the cleaned electroforming cylinder, then add the cylinder opening salt and cylinder opening agent; turn on the stirring device and the heating device;

[0022] B. Raise the liquid temperature of the electroforming cylinder to 40°C∽45°C; adjust the pH of the electroforming liquid with potassium hydroxide and phosphoric acid, and control the pH value of the liquid at 6.35∽6.85;

[0023] C. Add electroforming main salt potassium aurous cyanide and electroforming supplement to the electroforming cylinder to keep the gold content at 10-12g / L;

[0024] D. Hang the prepared casting coated with a conductive layer (which can be a conductive silver paste) as a cathode on a hanger and put it into an electroforming cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com