Method for producing an article made of a transparent material devoid of visible surface lines and the thus obtained article

A technology for surface treatment and products, applied in the field of transparent products, which can solve the problems of difficult to control deposits, large recommended thickness of coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0294] The following examples illustrate the invention.

[0295] In this example, unless otherwise stated, all percentages are percentages by weight, and the refractive index is measured at 25° C. and wavelength λ=550 nm.

[0296] For a refractive index n of base 6.75 (base = 530 / R in mm, where R is the radius of curvature of the lens), made from MR7 material (based on polythiourethane) sold by MITSUI D 25 A semi-finished spherical ophthalmic lens with a power of 1.660 and a power of -6.00 diopters was subjected to the surface treatment shown below.

[0297] Regardless of whether it is concave or convex, the surface treatment is carried out as follows:

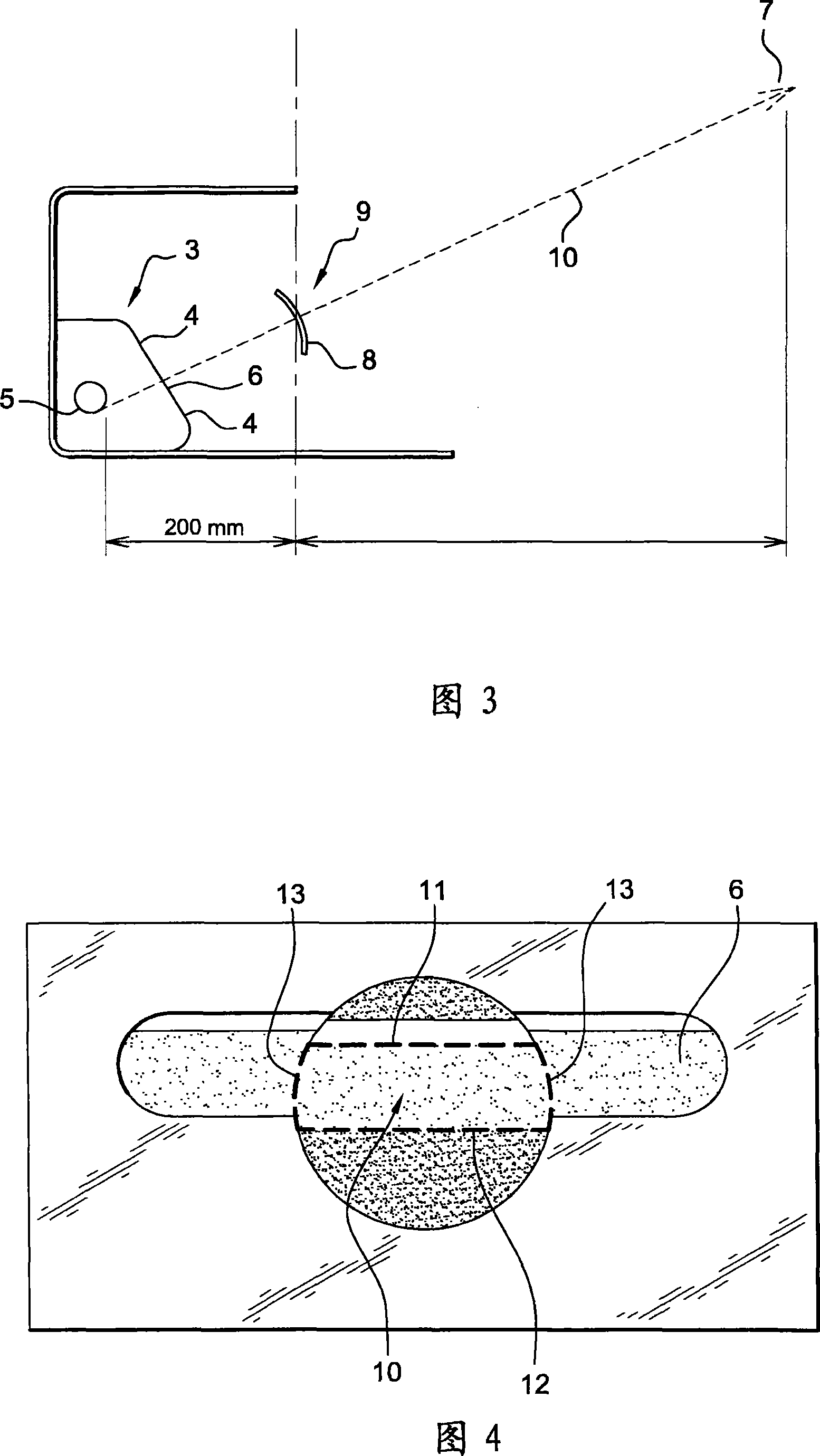

[0298] ●Processed on a SCHNEIDER HSC100 machine. Refining is carried out using a single crystal diamond tool with a radius of 2 mm, a rotational speed of less than or equal to 600 rpm, a forward motion of less than or equal to 0.04 mm / rev, and a depth of cut equal to 0.1 mm.

[0299] • Polishing on a SCHNEIDER CCP101 machi...

Embodiment 5 and 6

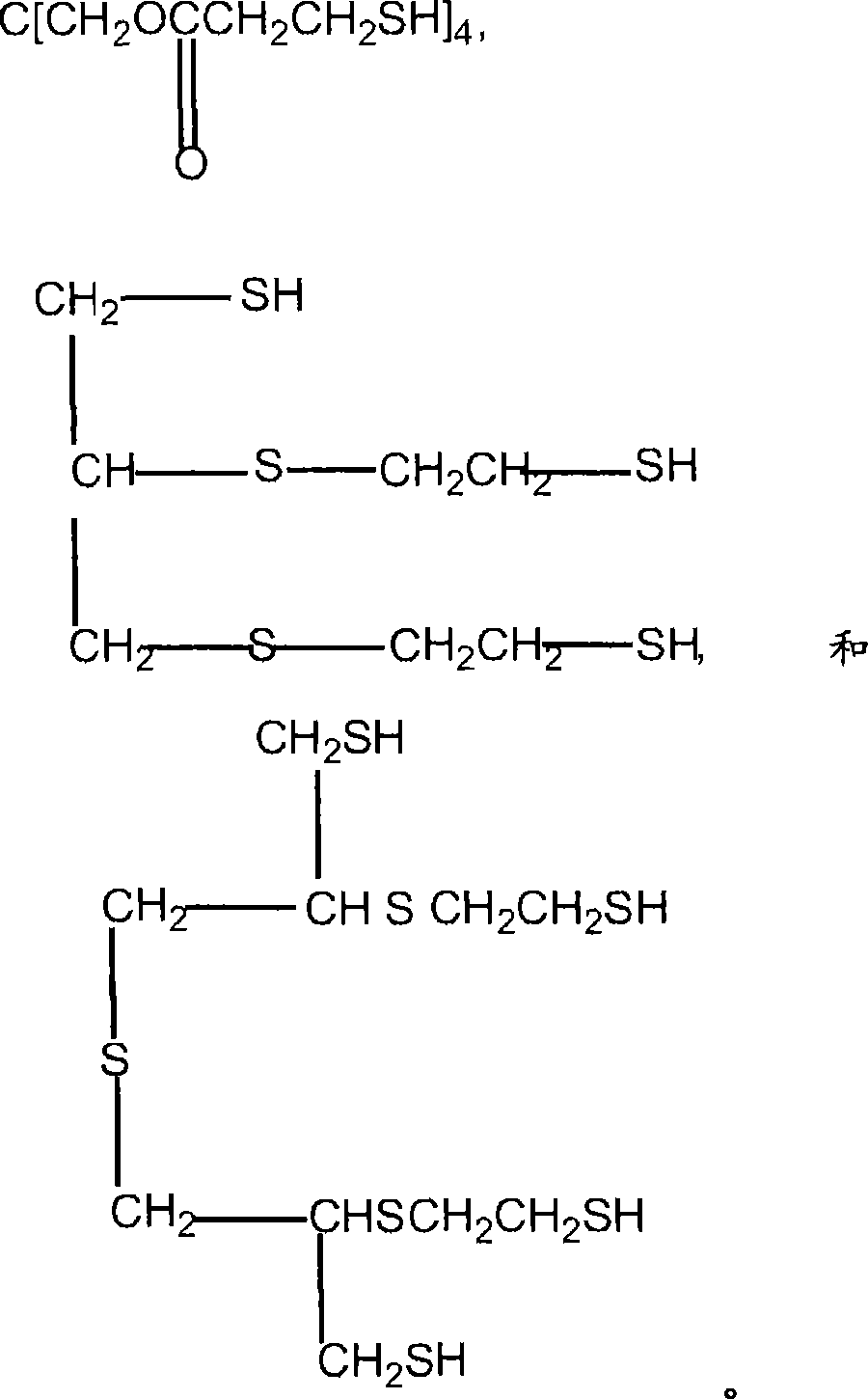

[0339] Examples 5 and 6: Deposition of coating compositions with variable contact angles

[0340] Using two different concentrations of the HMP solvent 4-hydroxy-4-methyl-2-pentanone (CH 3 ) 2 C(OH)CH 2 COCH 3 Two masking coating compositions were prepared: solution M3 (by diluting M2 at 70% by weight in HMP) and solution M4 (by diluting at 30% by weight in HMP). This changes the contact angle of the composition on a substrate with a refractive index of 1.67.

[0341] First, the contact angles of paint films M3 and M4 on molded double-sided 1.67 ophthalmic lenses were measured. The operating procedures are as follows:

[0342] The device used was DIGIDROP manufactured by GBX Instrumentation Scientifique. This is a device for automatic measurement of contact angle and wettability. DIGIDROP includes camera, image analysis and processing system and measurement program.

[0343] Droplet microcontrollers make it possible to deposit precise amounts of liquid simply using a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com