Method for synthesizing high purity carbon nano-ball and carbon microsphere

A carbon nanosphere and carbon microsphere technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of low carbon content, low purity, and high equipment requirements, and achieve high carbon content and high purity. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

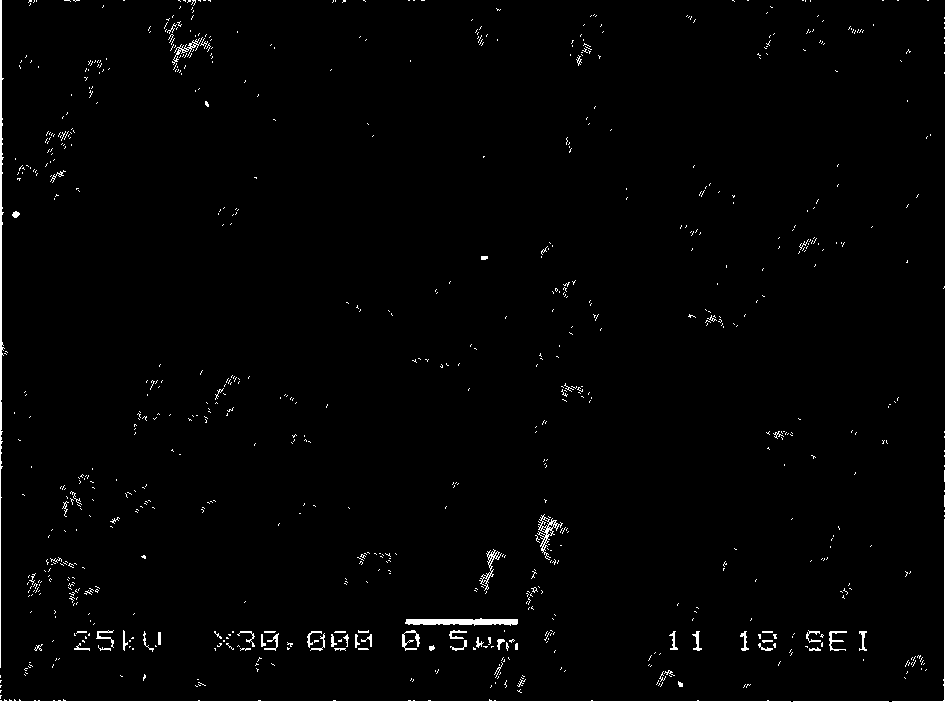

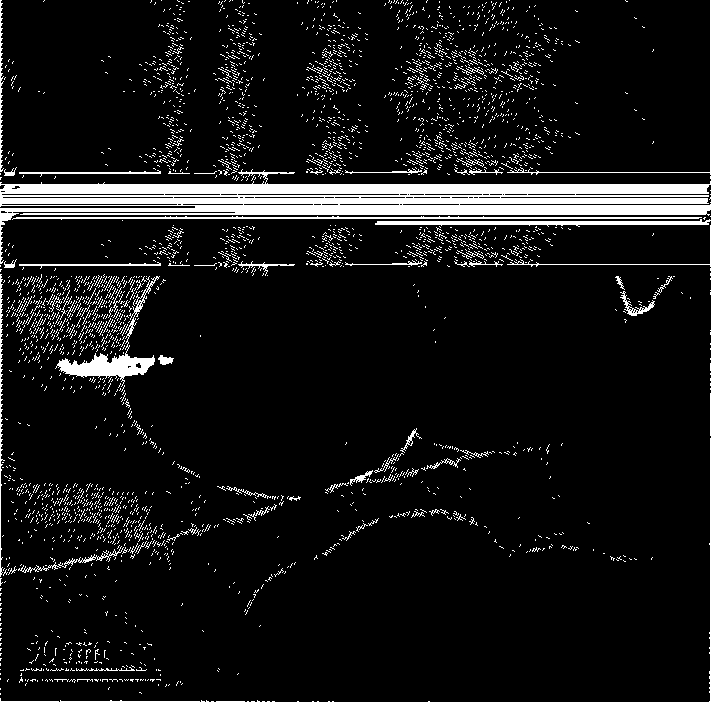

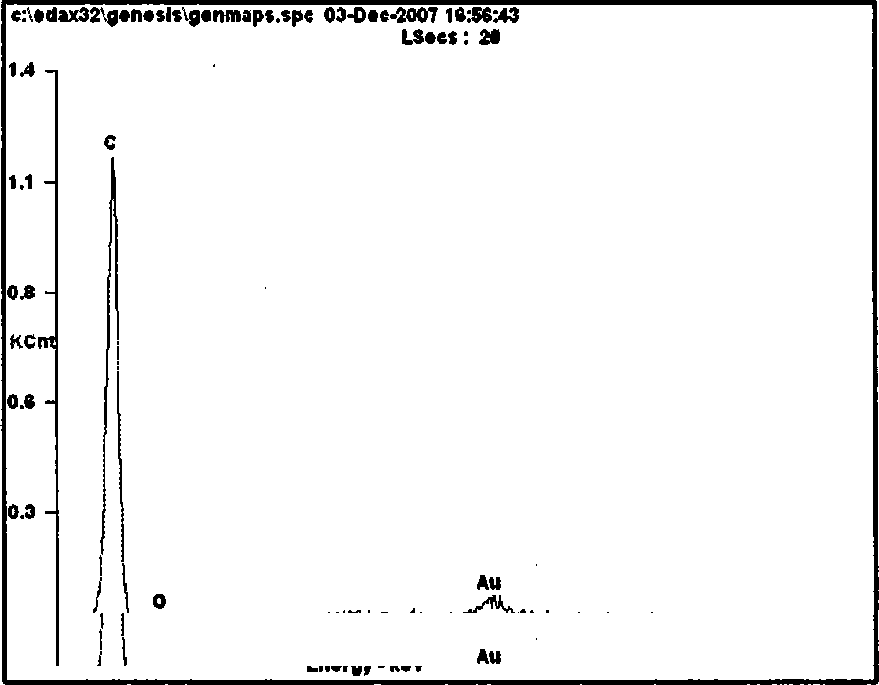

[0017] Embodiment 1: take by weighing 25 grams of CaC 2 (0.39mol) was placed in a 120 milliliter stainless steel pressure-resistant reactor, and crushed to particles with a diameter of 1-2 mm, while adding 25 grams (0.195mol) of oxalic acid dihydrate, and sealed the reactor. The reaction kettle is heated by a heating device, and the heating temperature is controlled by a temperature control device at the same time. When the temperature in the kettle rises to 65-80°C, the temperature in the kettle begins to rise sharply, and the temperature in the kettle can rise to about 250°C in a short time. Turn off the power supply of the heating device at this time, and the reactor is cooled to room temperature. After opening the lid of the reaction kettle, the reaction product is clearly divided into two layers; the upper layer is a bright black flocculent soft product with a product volume of about 2 grams; the lower layer is a yellow-white solid powder. The upper product is identifie...

Embodiment 2

[0018] Embodiment 2: take by weighing 30 grams of CaC 2 (0.468mol) was placed in a 120 milliliter stainless steel pressure-resistant reactor, crushed to particles with a diameter of 1-2 mm, and 20 grams (0.158mol) of oxalic acid dihydrate was added at the same time, and the reactor was sealed. The reaction kettle is heated by a heating device, and the heating temperature is controlled by a temperature control device at the same time. When the temperature in the kettle rises to 65-80°C, the temperature in the kettle begins to rise sharply, and the temperature in the kettle can rise to about 250°C in a short time. Turn off the power supply of the heating device at this time, and the reactor is cooled to room temperature. After opening the lid of the reaction kettle, the reaction product is clearly divided into two layers; the upper layer is a bright black flocculent soft product with a product volume of about 2 grams; the lower layer is a yellow-white solid powder. The upper p...

Embodiment 3

[0019] Embodiment 3: take by weighing 36 grams of CaC 2 (0.56mol) was placed in a 120 milliliter stainless steel pressure-resistant reactor, crushed to particles with a diameter of 1-2 mm, and 18 grams (0.143mol) of oxalic acid dihydrate was added at the same time, and the reactor was sealed. The reaction kettle is heated by a heating device, and the heating temperature is controlled by a temperature control device at the same time. When the temperature in the kettle rises to 65-80°C, the temperature in the kettle begins to rise sharply, and the temperature in the kettle can rise to about 250°C in a short time. Turn off the power supply of the heating device at this time, and the reactor is cooled to room temperature. After opening the lid of the reaction kettle, the reaction product is clearly divided into two layers; the upper layer is a bright black flocculent soft product with a product volume of about 1.25 grams; the lower layer is a yellow-white solid powder. The upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com