Oil-containing oil emulsion waste water treatment process

A wastewater treatment and emulsion technology, applied in the direction of oxidation water/sewage treatment, water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of large amount of demulsifier, high input cost, poor effect, etc. The effect of small area, low operating cost and high decolorization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

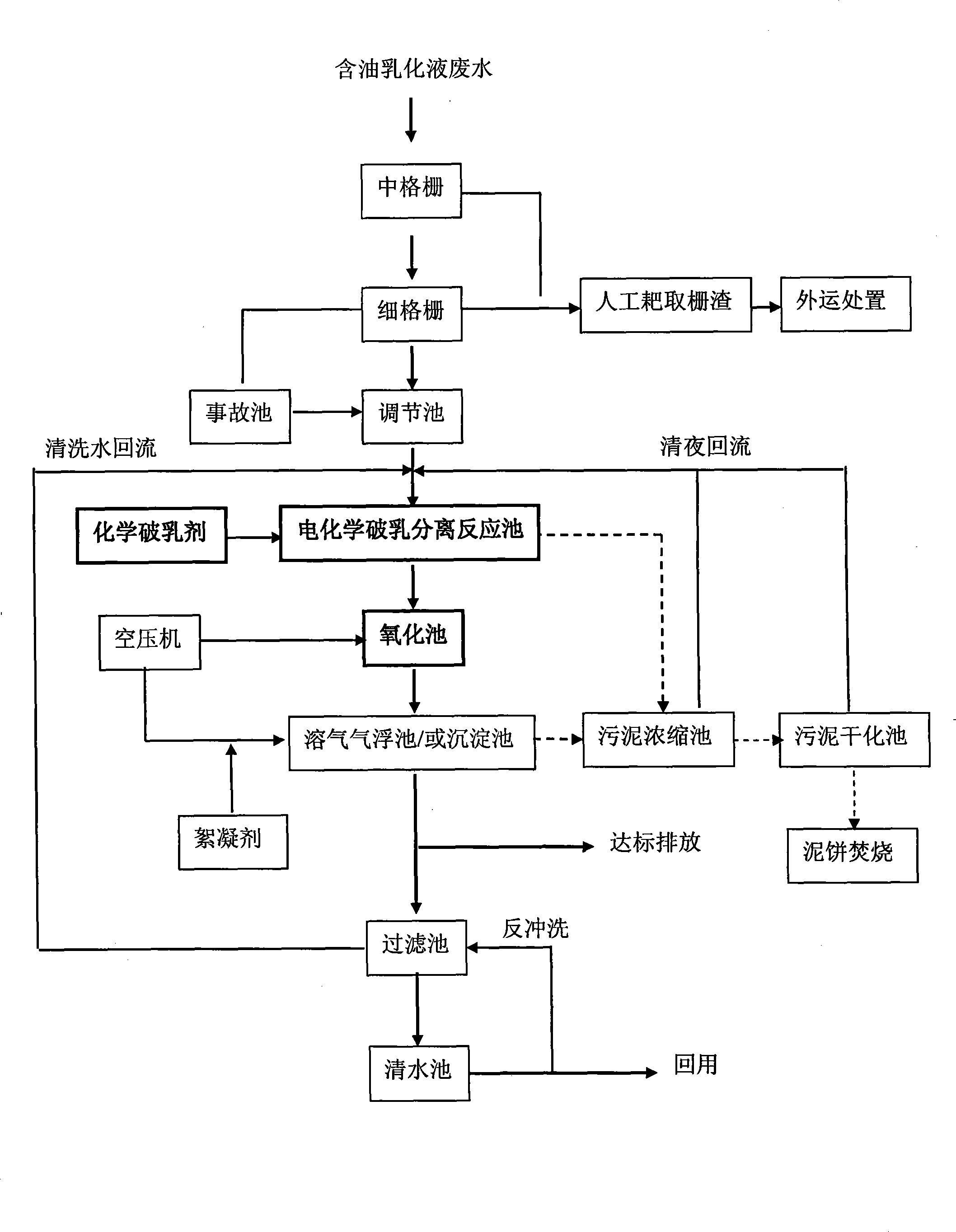

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0021] As shown in the accompanying drawings, the main process flow of the present invention is as follows: oily emulsion wastewater—grid pretreatment—water quality and quantity adjustment—electrochemical demulsification—oxidation—air flotation or precipitation—filtration—clear water . The specific methods of each treatment process in the above-mentioned technological process are as follows:

[0022] (1) In the grid pretreatment process of the process, two grid pretreatments, medium and fine, have been performed successively; the gap of the medium grid is 20mm, and the gap of the fine grid is 5mm, and a manual grid or a mechanical grid can be used. The length or diameter of the impurities contained in the waste water filtered by the grid is less than 5mm; the material of the immersed part is stainless steel, which can be anti-corrosion; the working temperature is 1-5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com