Deep borehole rock deformation testing device

A technology for deformation testing and rock mass, which is applied in the direction of measuring devices, electric/magnetic solid deformation measurement, electromagnetic measuring devices, etc., can solve problems such as difficult to determine the correction coefficient, inapplicability, uneven force on rock mass, etc., and achieve the elimination of displacement The effect of measurement error, uniform pressure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

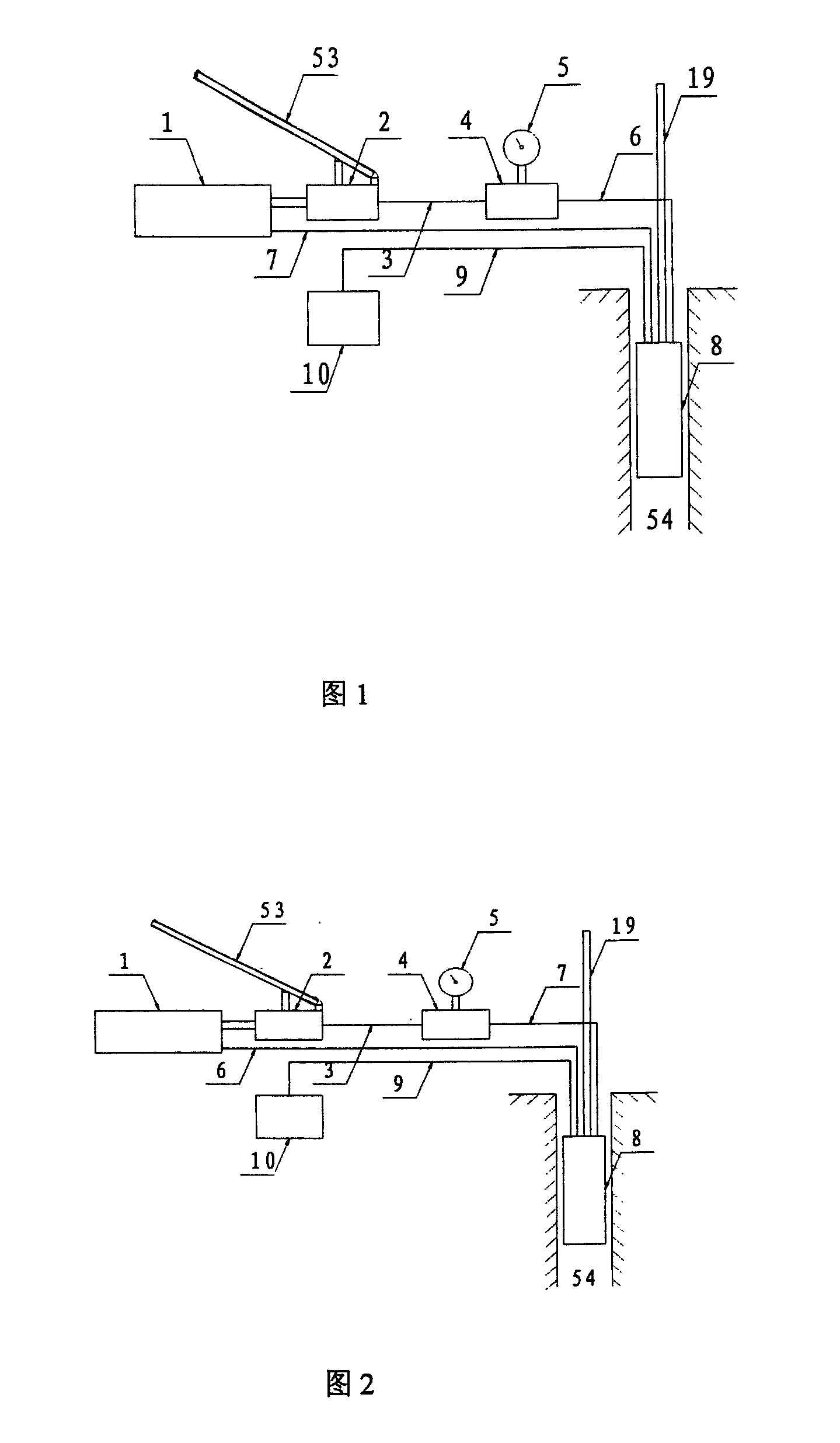

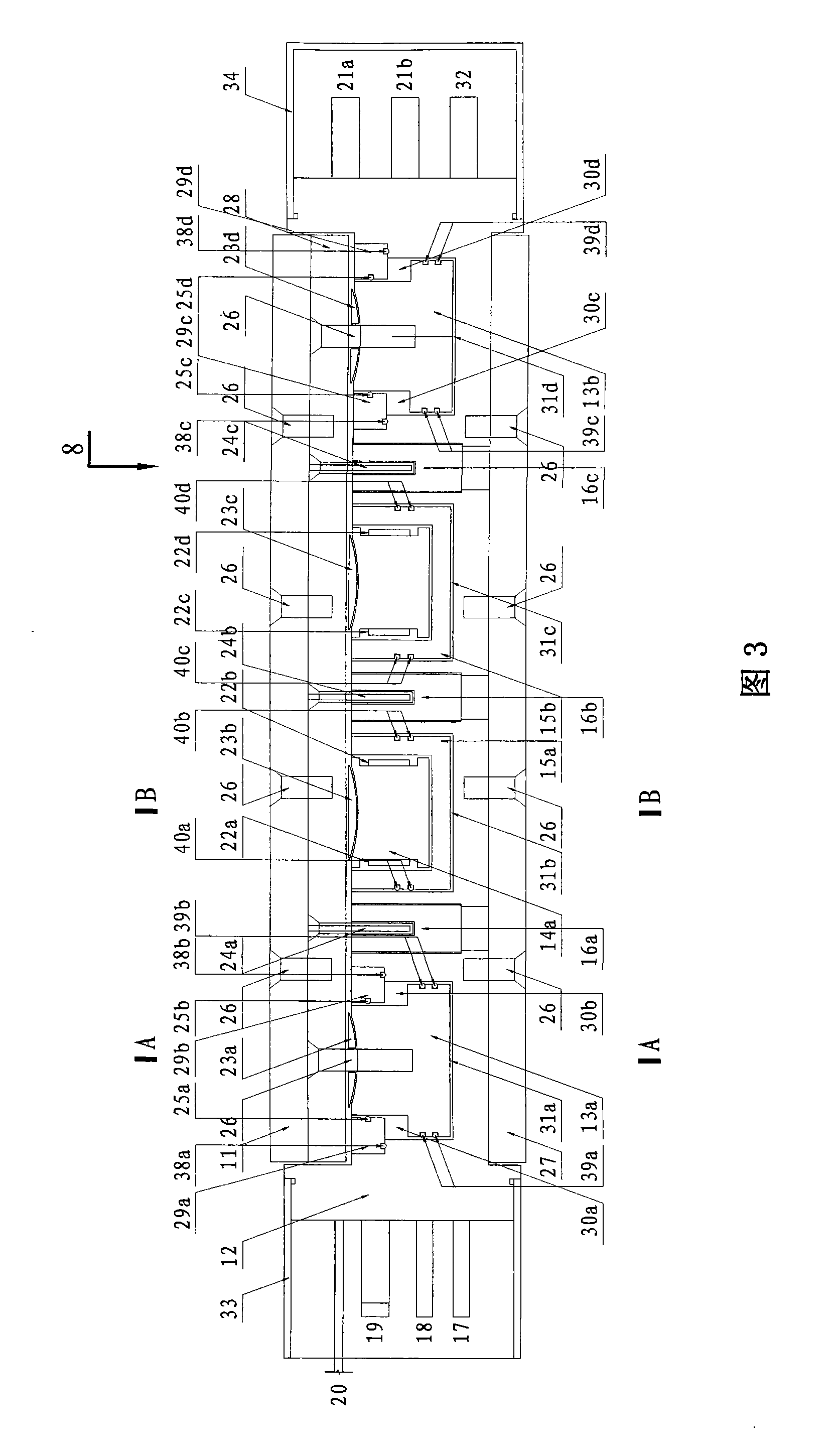

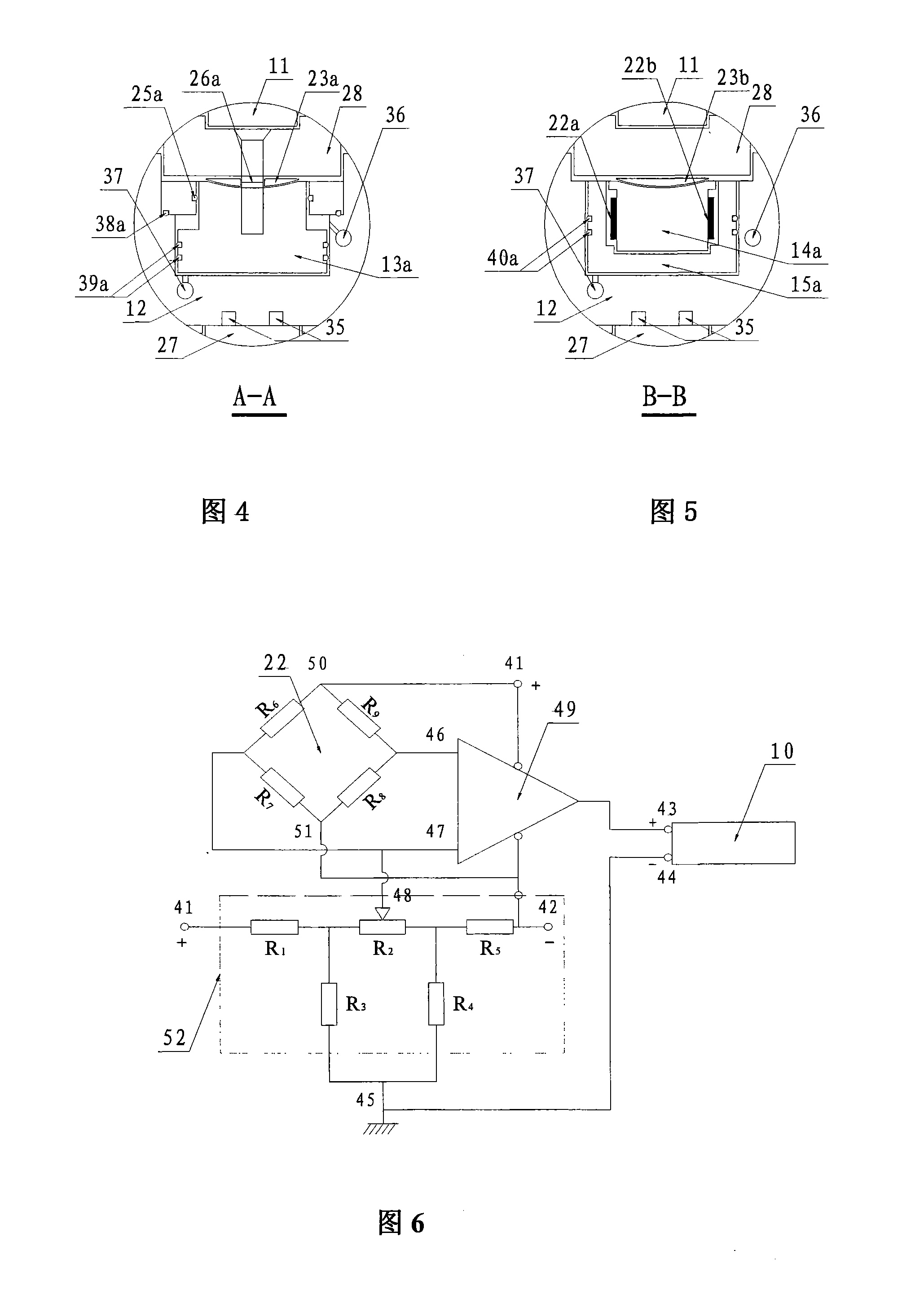

[0058] According to Fig. 1, Fig. 2, Fig. 3, it can be seen that the hydraulic oil pump 2 is respectively connected with the hydraulic oil tank 1 and the high-pressure oil pipe 3, and the hydraulic oil pump 2 is pulled and pressed by the handle 53 to provide hydraulic pressure; the high-pressure oil pipe 3 is connected with the tee 4; the tee 4 is respectively connected with the The high-pressure oil pipe 3, the precision pressure gauge 5, and the process high-pressure oil pipe 6 are connected, and the precision pressure gauge monitors the applied hydraulic pressure; the process high-pressure oil pipe 6 is connected with the process piston oil circuit interface 17 in the drilling rock mass deformation tester 8, and the drilling rock The body deformation tester 8 is put into the predetermined depth of the borehole 54 through the installation rod 19 (controlling the measurement depth of the drilling deformation tester), and the installation rod 19 is fixed on the lifting device (om...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com