Method and circuit of driving electron-emitting device, electron source, and image-forming apparatus

一种电子发射装置、电子发射的技术,应用在电路、放电管电子枪、放电管主电极等方向,能够解决降低图象对比度等问题,达到抑制电子发射、高性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

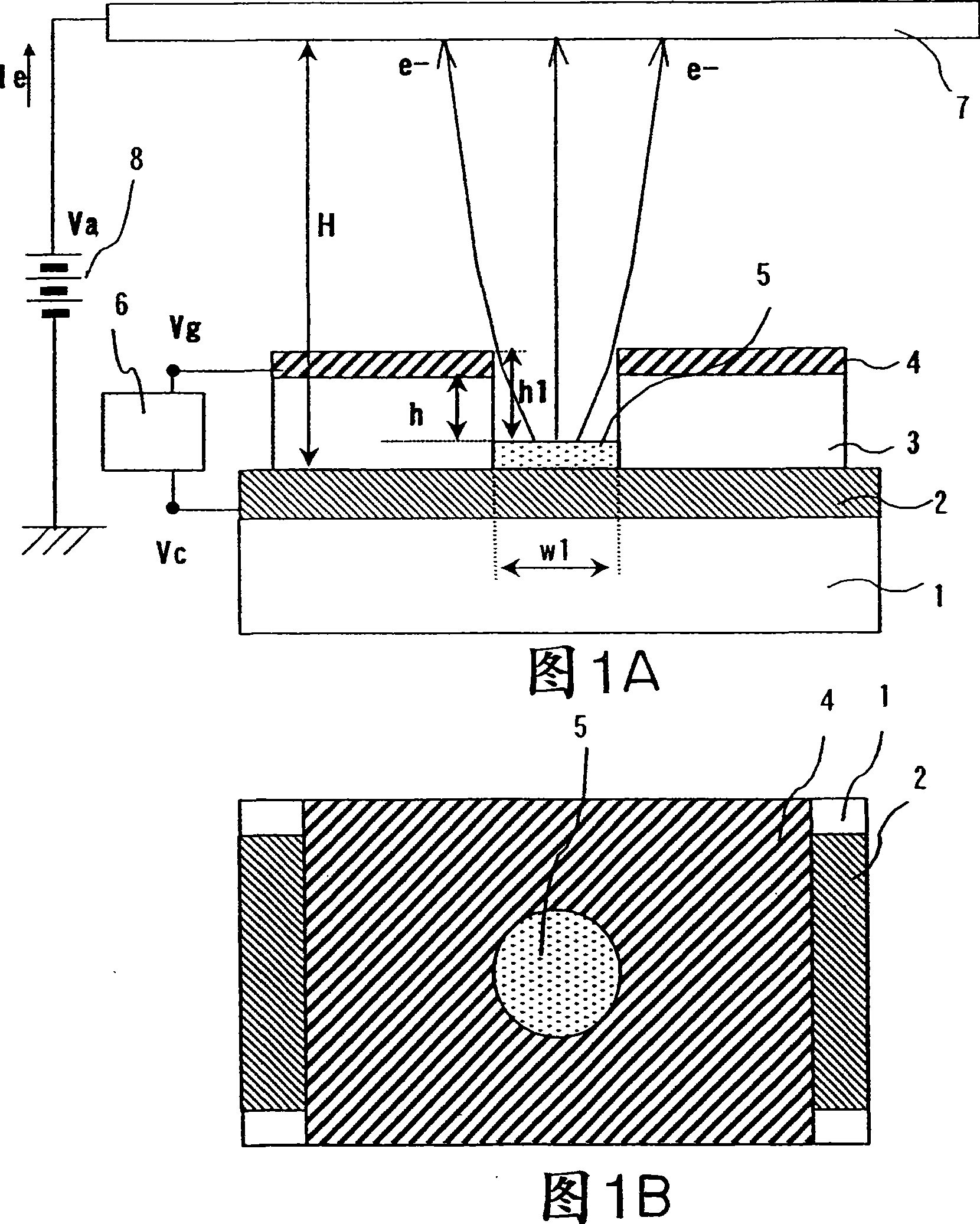

[0224] 1A and 1B are a plan view and a cross-sectional view of the electron-emitting device of the first embodiment, and FIG. 6 shows a method of manufacturing the device. A method of manufacturing the electron emission device of this example is described in detail below.

[0225] (step 1)

[0226] First, as shown in FIG. 6A, a substrate 1 is prepared by sufficiently cleaning quartz glass. Next, a Ta thin film with a thickness of 300 nm was formed as the cathode electrode 2 by a sputtering method.

[0227] (step 2)

[0228] Next, as shown in FIG. 6B, an insulating layer 3 and a gate electrode 4 are stacked in sequence, wherein the insulating layer 3 is SiO with a thickness of 600 nm. 2 thin film, the gate electrode 4 is a Ta thin film with a thickness of 100 nm.

[0229] (step 3)

[0230] Then, as shown in FIG. 6C, a photomask pattern of a positive photoresist (AZ1500 manufactured by Clariant) was formed by spin coating, exposed to light, and developed using photolithogra...

no. 2 example

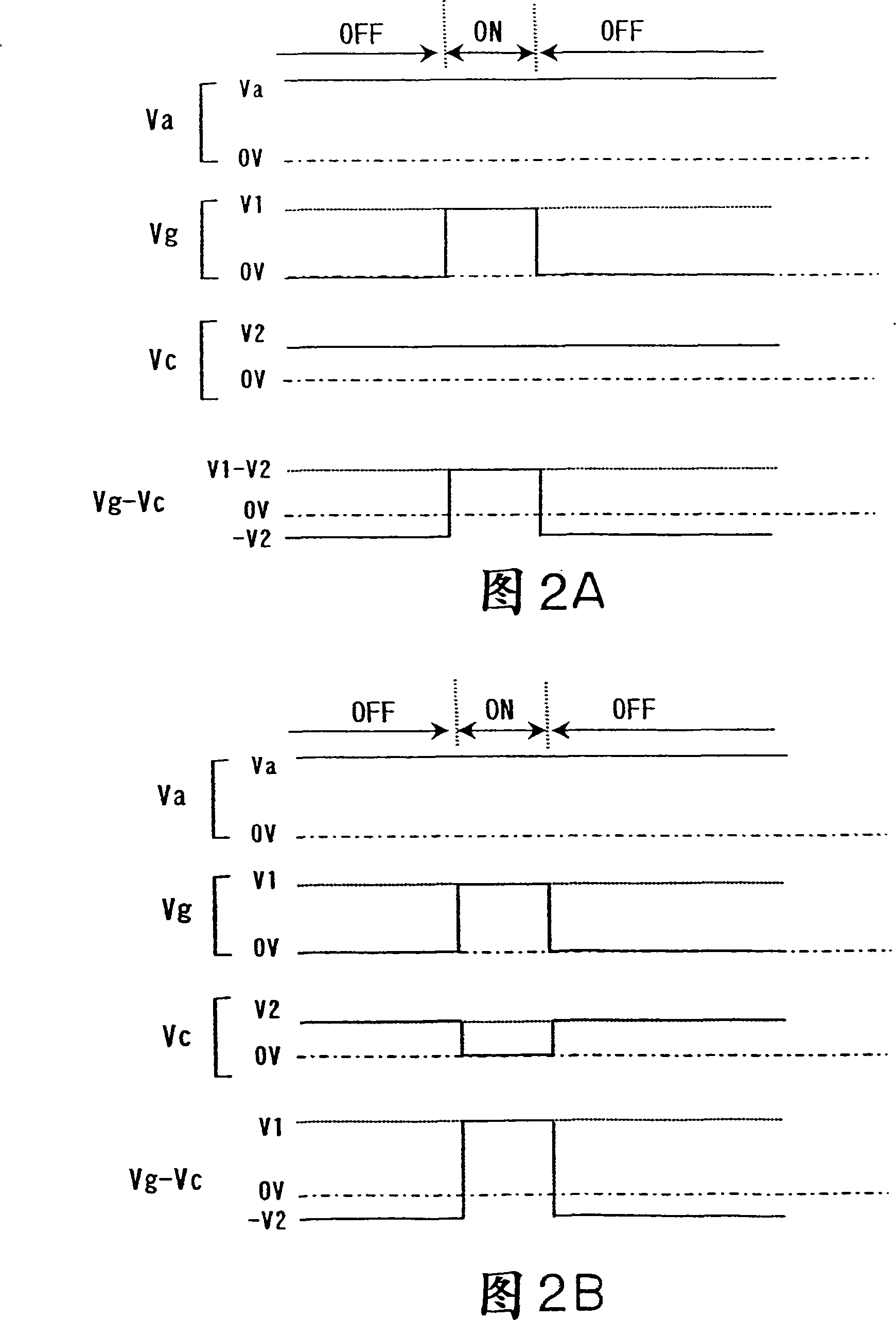

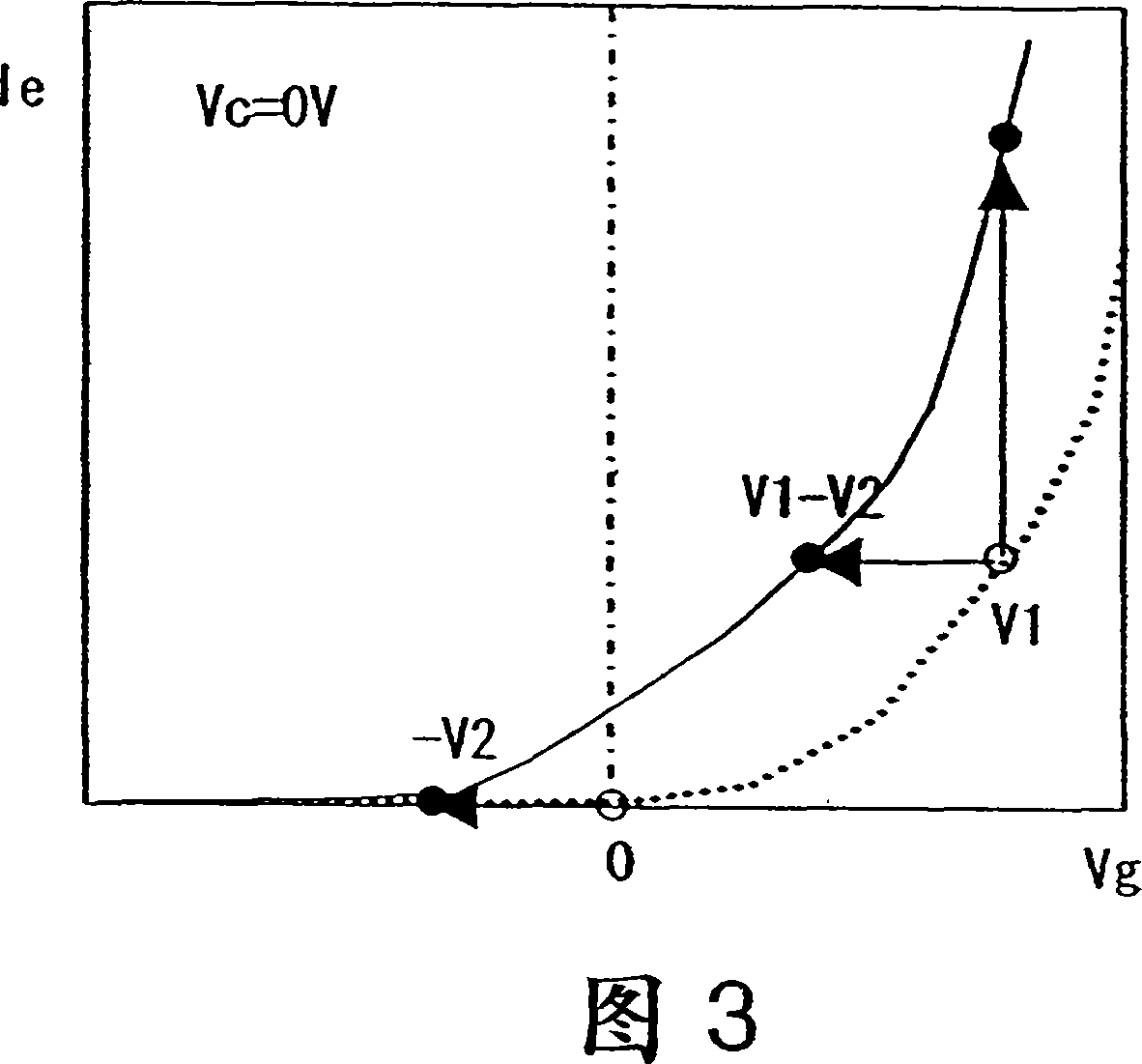

[0244]Another control method of the present invention is described in this embodiment.

[0245] As in the first embodiment, the electron-emitting device shown in FIG. 1 is also used in this embodiment. However, the distance H between the device and the anode electrode 7 was set to 1 mm, and the anode electrode voltage Va was set to 15 KV in this embodiment.

[0246] The control operation shown in FIG. 2B is performed in this embodiment. In addition, as the second comparative example, the voltages V1 and V2 can be set to 15V and 0V, respectively, like the first comparative example described in the first embodiment.

[0247] With this structure of this example, the electric field strength between the device and the anode electrode 7 is three times that of the first embodiment.

[0248] If the voltage V2 is set to 2V as in the first embodiment, the electron emission current Ie remains in the OFF period. Therefore, the voltage V2 is set to 4V. On the other hand, even if the vo...

no. 3 example

[0254] In this embodiment, the image forming apparatus shown in FIG. 9 is constructed using an electron source including a plurality of electron emission devices of the second embodiment, which are wired in a matrix as shown in FIG. 7 . In addition, the driving circuit shown in FIG. 11 is formed in the device and the control operation shown in FIG. 12 is executed. The voltages Vx1, Vx2, and Vy1 are set to 4V, 20V, and 16V, respectively. In addition, like the second embodiment, as a third comparative example, the voltages V1 and V2 are set to 16V and 0V, respectively, and the voltages Vg and Vc in the OFF stage are both set to 0V. In order to compare Control devices with passive matrix configuration.

[0255] The electron-emitting devices may be arranged such that both the X-direction interval and the Y-direction interval are set to 150 μm. A fluorescent film 74 is provided on the device. In the third comparative example, the contrast was lowered due to this structure, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com