Method for reinforcing optical capturing effect of thin film photovoltaic device

A photovoltaic device and thin-film silicon technology, applied in the field of solar photovoltaic equipment, can solve the problem that the reflected light cannot reach the critical angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

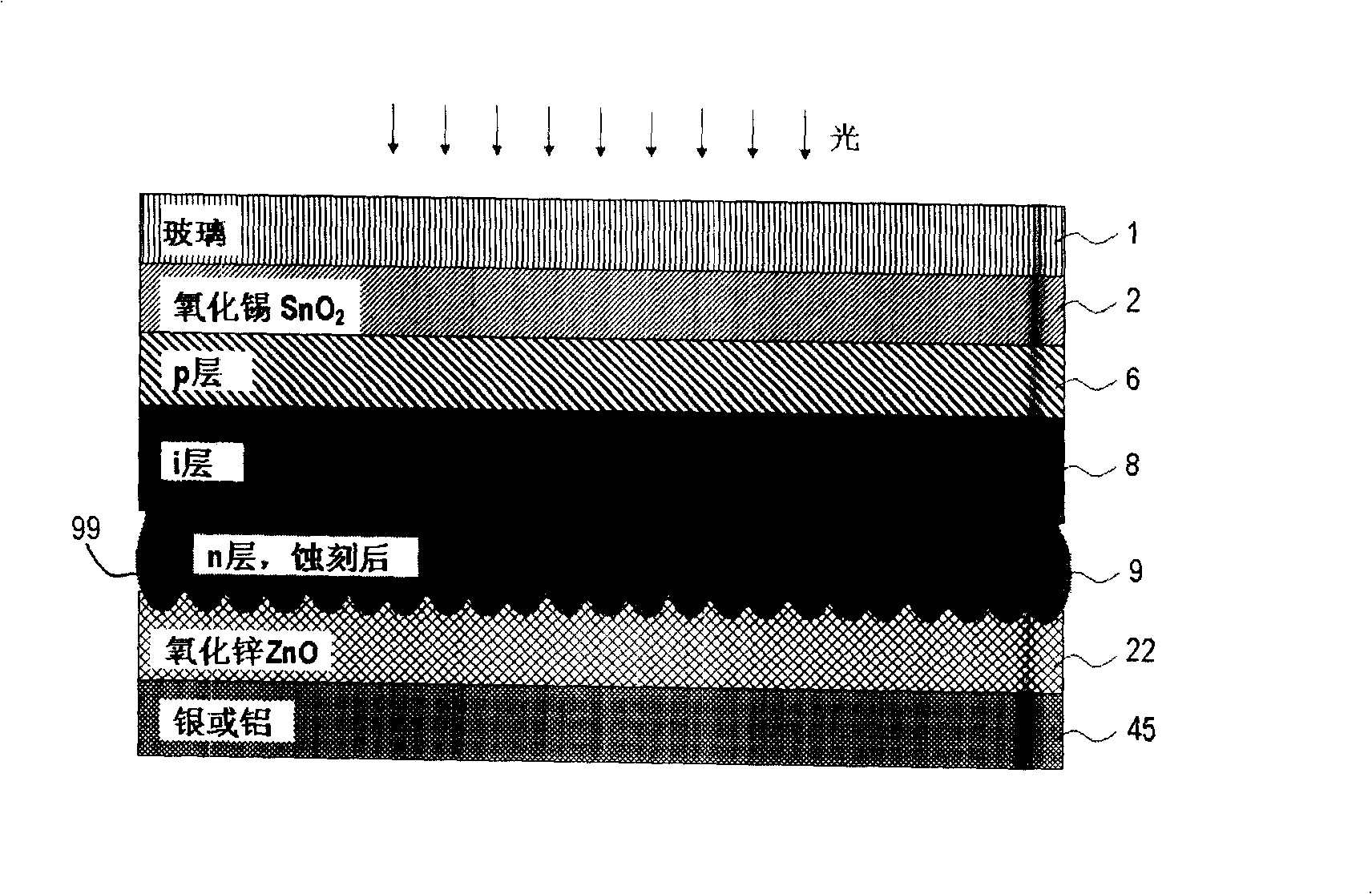

[0011] As shown in the accompanying drawing, a p-i-n type photovoltaic device comprises: a glass substrate 1; a transparent conductive front contact layer 2, a boron-doped p-layer 6 based on thin-film silicon, an intrinsic thin-film silicon-based i-layer 8 , a phosphorus-doped n-layer 9 based on thin-film silicon and a highly reflective back electrode composed of metal oxide 22 and metal film 45 . When the p-i-n layer is obtained by plasma-enhanced chemical vapor deposition, the present invention intentionally makes the n-layer relatively thick, such as not less than 300 nanometers. After this, the device is treated with an etch plasma, using plasma source gases including hydrogen, fluorine-containing gases, and chlorine-containing gases, such as NF 3 , CCl 4 . This plasma etching process is carried out under relatively high pressure, such as greater than 4mbar, and at relatively high power, so that the etching process has obvious regional and non-uniformity. As a result, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com