Praseodymium-holmium-codoped rare earth stannate up-conversion luminescent material and its preparation method and use

A technology of luminescent materials and co-doping, which is applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

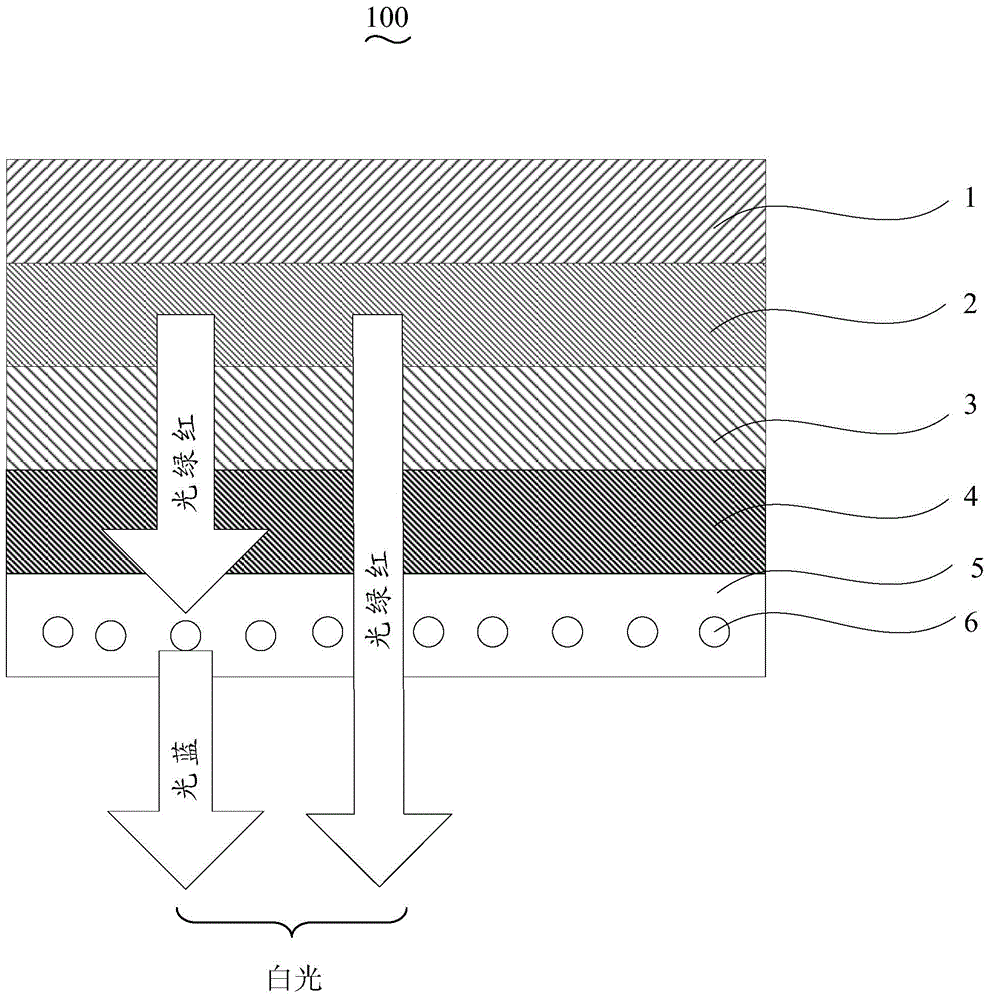

[0030] The preparation method of the above-mentioned praseodymium-holmium co-doped rare earth stannate up-conversion luminescent material comprises the following steps;

[0031] Step S101, according to the chemical formula Me 2-x-y SnO 5 :xPr 3+ ,yHo 3+ The stoichiometric ratio of each element in is weighed as Me 2 o 3 , SnO 2 、Pr 2 o 3and Ho 2 o 3 Powder, wherein, x is 0.002-0.06, y is 0.002-0.04, and the Me 2 o 3 It is yttrium oxide, lanthanum oxide, gadolinium oxide or lutetium oxide.

[0032] Preferably, x is 0.03 and y is 0.01.

[0033] The Me 2 o 3 , SnO 2 、Pr 2 o 3 and Ho 2 o 3 The powder molar ratio is (2-x-y): 2:x:y.

[0034] Step S102, dissolving the weighed powder in nitric acid to prepare a mixed solution; the Me 2 o 3 , SnO 2 、Pr 2 o 3 and Ho 2 o 3 The total concentration of the powder in the mixed solution is 0.5mol / L-3mol / L; then a dispersant is added to the mixed solution to obtain a precursor solution;

[0035] Preferably, the Me 2...

Embodiment 1

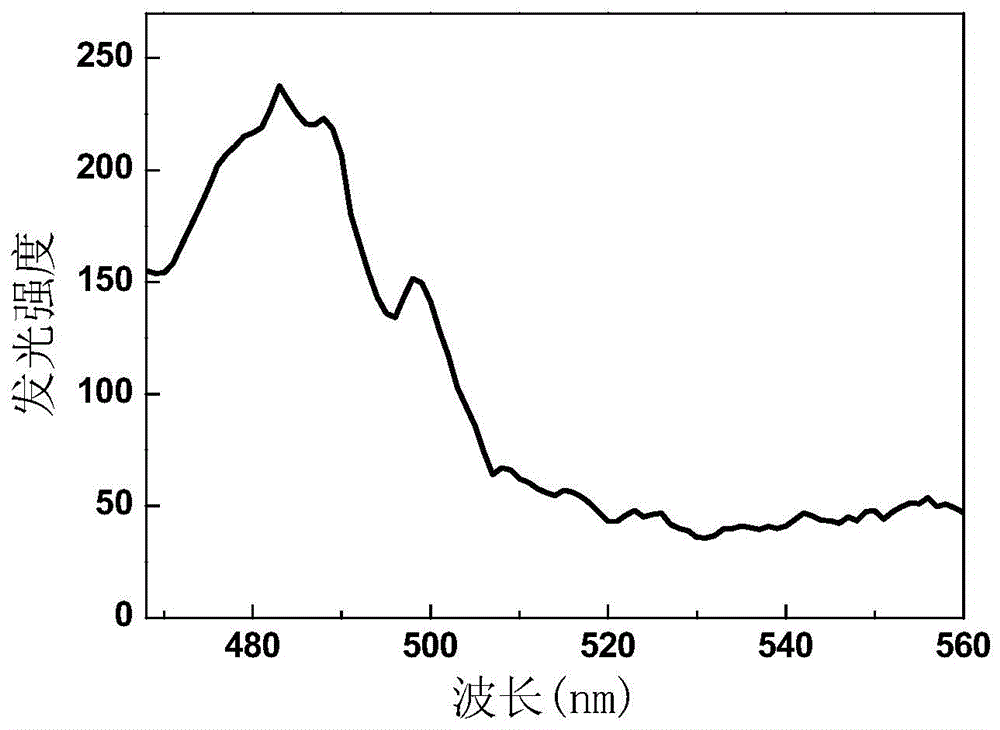

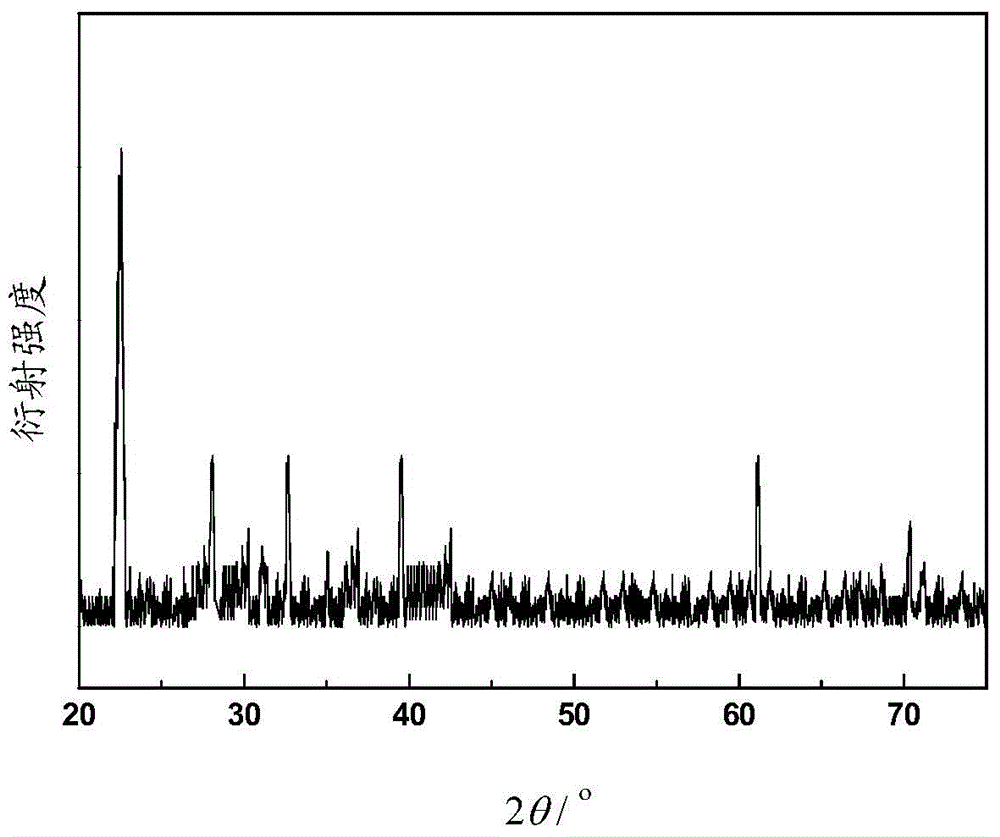

[0050] Weigh Y respectively according to the ratio of 1.96:2:0.03:0.01 in molar ratio 2 o 3 , SnO 2 , Pr 2 o 3 and Ho 2 o 3 The powder is dissolved in nitric acid to prepare a 1.5mol / L mixed solution, and polyethylene glycol is added as an additive to obtain a precursor solution; the concentration of polyethylene glycol in the precursor solution is 0.01mol / L. Then put the precursor solution into the atomization device, and then feed 5 L / min argon into the atomization device. The precursor solution enters a quartz tube with an inlet temperature of 180°C and an outlet temperature of 110°C along with the argon carrier gas to generate a precursor. The diameter of the quartz tube is 30mm and the length is 3m. The precursor is collected and placed in a temperature-programmed furnace for calcination for 3 hours, the calcination temperature is 1100°C, and the chemical formula is Y 1.96 SnO 5 : 0.03Pr 3+ , 0.01Ho 3+ up-converting luminescent materials.

[0051] see figure ...

Embodiment 2

[0056] Weigh Y respectively according to the ratio of 1.9:2:0.06:0.04 in molar ratio 2 o 3 , SnO, Pr 2 o 3 and Ho 2 o 3 The powder was dissolved in nitric acid to prepare a mixed solution of 3 mol / L, and polyethylene glycol was added as an additive to obtain a precursor solution; the concentration of polyethylene glycol in the precursor solution was 0.05 mol / L. Then put the precursor solution into the atomization device, and then feed 15 L / min argon gas into the atomization device. The precursor solution enters a quartz tube with an inlet temperature of 220°C and an outlet temperature of 130°C along with the argon carrier gas to form a precursor. The diameter of the quartz tube is 150mm and the length is 0.5m. The precursor is collected and placed in a temperature-programmed furnace for calcination. After 5 hours, the calcination temperature is 1300°C, and the chemical formula is Y 1.9 SnO 5 : 0.06Pr 3+ , 0.04Ho 3+ Up-converting luminescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com