Interplant monomer between ridges with bidirectional profile modeling function

A single and functional technology, applied in fertilizers and planting equipment, agricultural machinery and implements, shovels, etc., can solve the problems of freezing and dying of wheat seedlings, short crop growth time, and only idle land, achieving novel and unique structure and high operating quality. Good, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

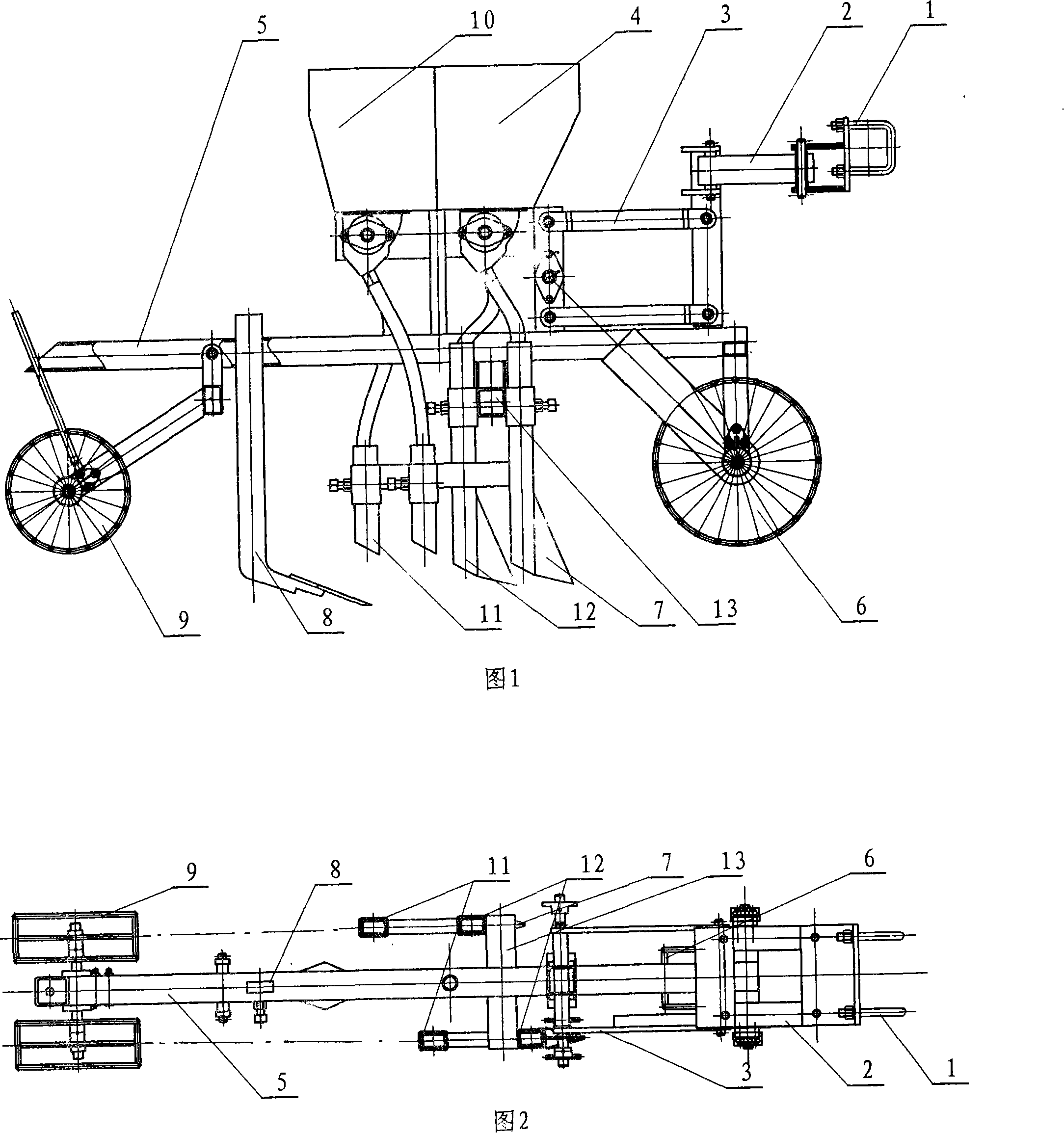

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A sowing unit with two-way profiling function interleaved between ridges, on the rear side of a horizontal four-bar profiling mechanism 2 configured horizontally, a vertical four-bar profiling mechanism 3 configured vertically is hinged and equipped, and a single beam Frame welding 5 hinged connection is installed on the lower part of the rear side of vertical four-bar profiling mechanism 3, and the upper part of single beam frame welding 5 is equipped with fertilizer box and fertilizer discharger assembly 4 and seed box and seed metering device assembly 10 , the driving ground wheel 6, the welding of the seed fertilizer pipe installation frame 13, the subsoiling shovel assembly 8 and the pressing wheel 9 are installed on the lower part of the single beam frame welding 5 from front to back in sequence; the rigid fertilizer feeding pipe 12 and the rigid fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com