Method for high-density fermentation of pichia pastoris of insulin precurosor protein

An insulin precursor, high-density fermentation technology, applied in the field of microorganisms, can solve the problems of complex operation and high cost, and achieve the effects of simple process, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

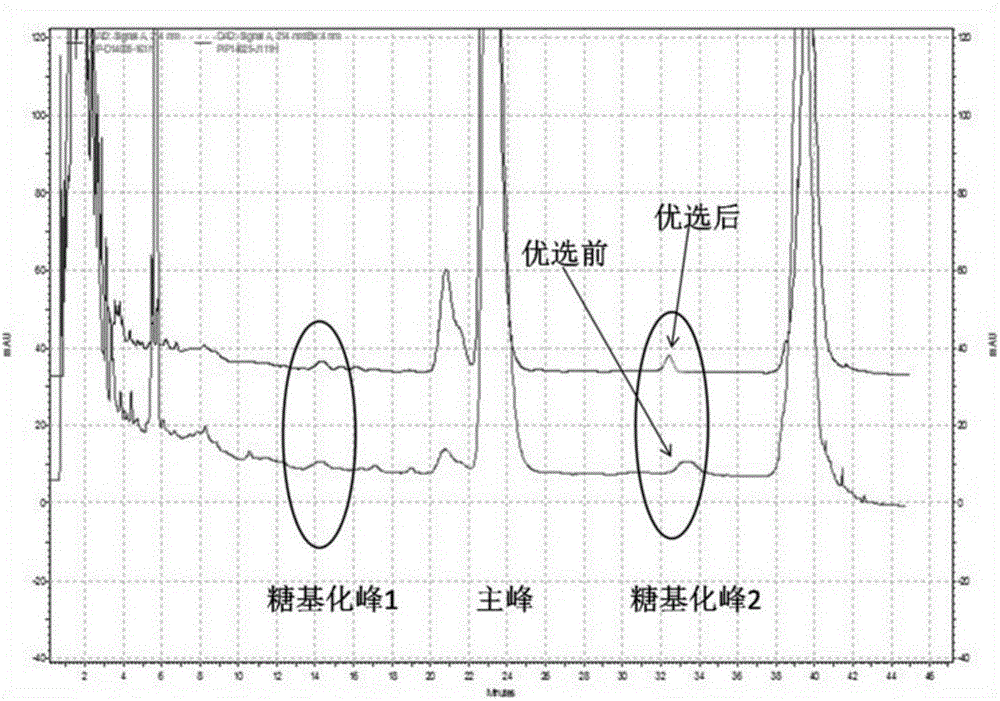

Image

Examples

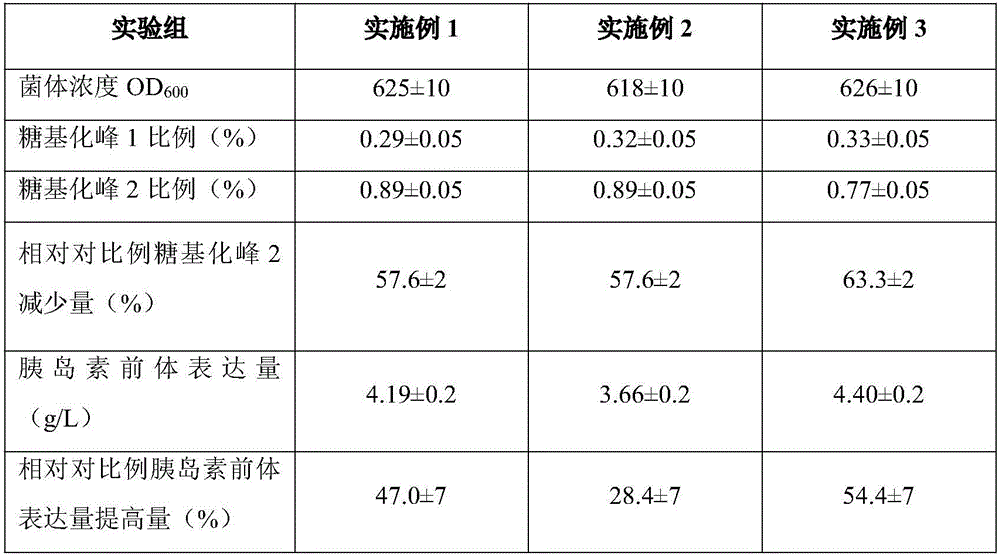

Embodiment 1

[0032] Object: GS115 Pichia pastoris (purchased from Invitrogen, USA) was used to ferment and express recombinant human insulin precursor

[0033] Strain expansion: inoculate the activated strains into the seed medium, shake and cultivate at 28°C for 10 hours, then transfer to the secondary seed medium at a volume ratio of 0.5%, and shake and cultivate at 28°C for 20 hours;

[0034]Fermentation culture: 1) Batch growth stage: inoculate the strains after the expansion into the fermentation medium, the inoculation volume of the strains is 2.5% of the volume of the fermentation medium, and the dissolved oxygen is controlled by the rotating speed to be greater than or equal to 50%. Cultivate at ℃ until the dissolved oxygen rebounds to 80%; 2) Glycerin supplementation stage: supplement glycerin solution at a rate of 25g / L / h, control dissolved oxygen ≥ 30% by rotating speed, and add urea to control the pH value at 4.0, Cultivate until the cell concentration is OD 600 =200, stop add...

Embodiment 2

[0038] Object: Pichia pastoris GS115 (purchased from Invitrogen, USA) was used to ferment and express recombinant human insulin precursor.

[0039] Strain expansion: inoculate the activated strains into the seed medium, shake and culture at 32°C for 14 hours, then transfer to the secondary seed medium at a volume ratio of 1.5%, and shake and cultivate at 32°C for 24 hours;

[0040] Fermentation culture: 1) Batch growth stage: inoculate the strains after the expansion into the fermentation medium, the inoculation volume of the strains is 2.5% of the volume of the fermentation medium, control the dissolved oxygen ≥ 50% by rotating speed, at 32 Cultivate at ℃ until the dissolved oxygen rebounds to 80%; 2) Glycerin supplementation stage: supplement glycerol solution at a rate of 18g / L / h, control dissolved oxygen ≥ 30% by rotating speed, and add urea to control the pH value at 5.0, Cultivate until the cell concentration is OD 600 =300, stop adding glycerin; 3) Methanol induction s...

Embodiment 3

[0044] Object: Pichia pastoris GS115 (purchased from Invitrogen, USA) was used to ferment and express recombinant human insulin precursor.

[0045] Strain expansion: Inoculate the activated strains into the seed medium, shake and culture at 30°C for 10-14 hours, then transfer to the secondary seed medium at a volume ratio of 1.0%, and shake and culture at 30°C for 22 hours ;

[0046] Fermentation culture: 1) Batch growth stage: inoculate the strains after the expansion into the fermentation medium, the inoculation volume of the strains is 2.5% of the volume of the fermentation medium, control the dissolved oxygen ≥ 50% by rotating speed, at 30 Cultivate at ℃ until the dissolved oxygen rebounds to 80%; 2) Glycerol supplementation stage: supplement glycerin solution at a rate of 20g / L / h, control dissolved oxygen ≥ 30% by rotating speed, and add urea to control the pH value at 5.0, Cultivate until the cell concentration is OD 600 Stop adding glycerin at 250 ℃; 3) Methanol induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com