Composite purification regulating and controlling system for water body in cultivation pond

A technology of compound purification and regulation system is applied in the field of purification regulation system of freshwater pond aquaculture water body, which can solve the problems of unfavorable aquaculture needs, high cost of water purification and treatment, and high energy consumption, so as to improve oxygenation efficiency and energy saving needs, Improve biochemical efficiency and water purification effect, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

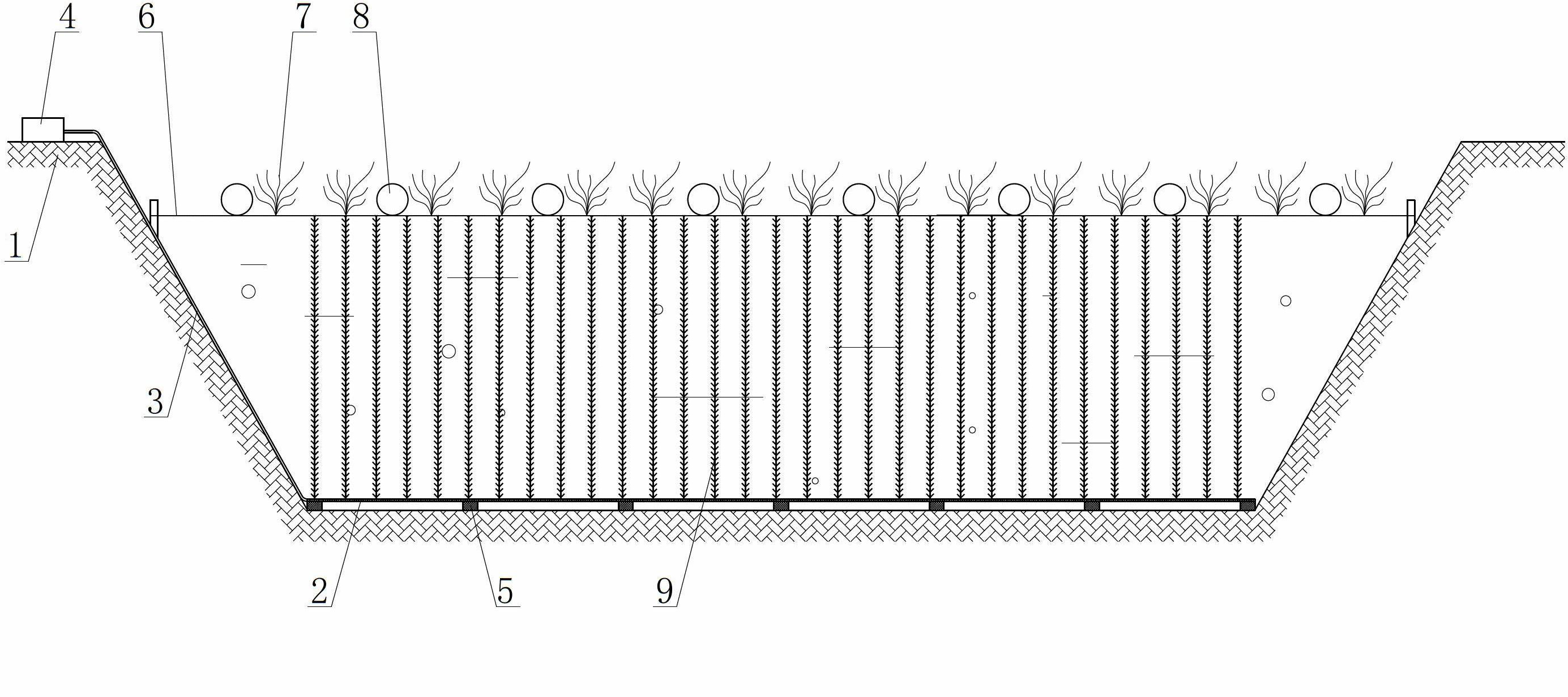

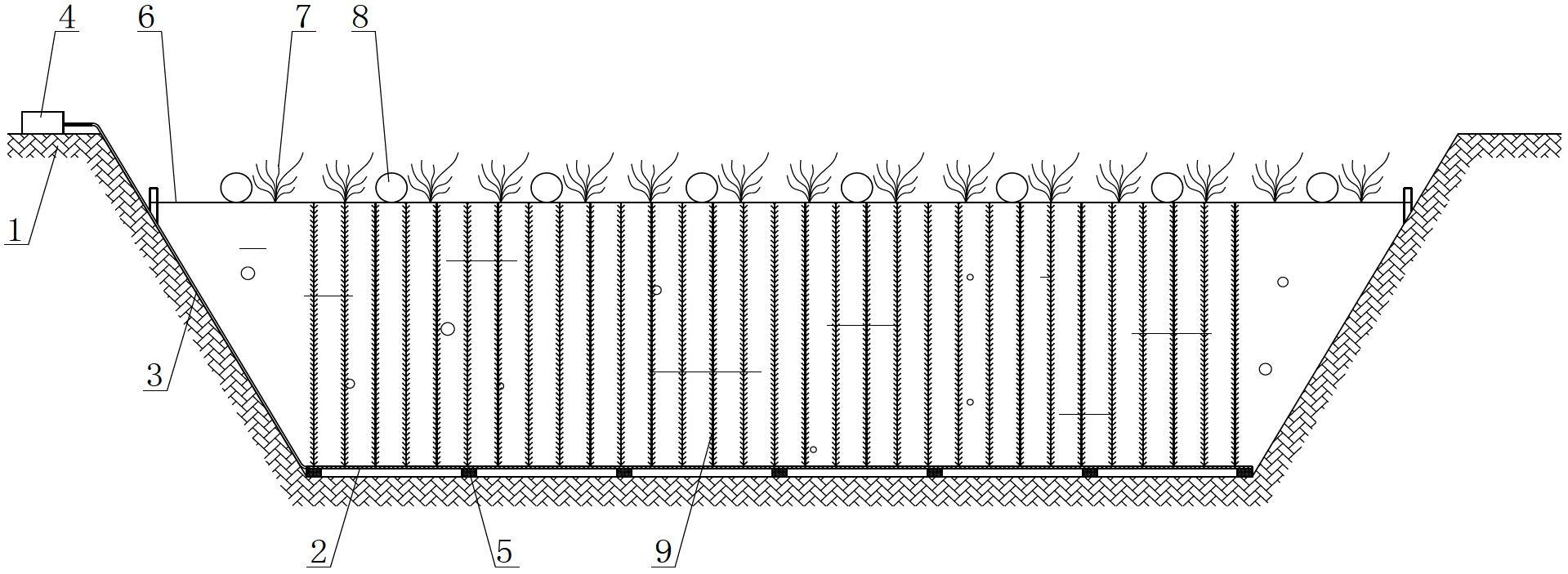

[0031] The present invention will be further described below in conjunction with accompanying drawing.

[0032] figure 1 Among them, the ridges 1 on both sides of the culture pond are perpendicular to each other, and a plurality of aeration pipes 2 are arranged in parallel at the bottom of the pond. The aeration pipes 2 are microporous aeration pipes. The two ends of the trachea 2 are respectively close to the pond ridges 1 on both sides of the breeding pond, and one end is a closed end, and one end is connected to the air outlet of the blower 4 arranged on the pond ridge 1 through the air distribution pipe 3, and the blower 4 is a Roots blower for aeration. The ratio of the total length of the tube 2 to the power of the Roots blower is 400m / Kw.

[0033] A plurality of heavy objects 5 are uniformly fixed along the length direction of the aeration pipe 2, and the aeration pipe 2 is fixed on the bottom of the culture pond.

[0034] An upper strand rope 6 is correspondingly arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com