Gear pump using water as pressure medium

A technology of hydraulic medium and application of water, applied in the field of hydraulic gear pump, can solve the problems of difficult processing and assembly, weak anti-pollution ability, short service life, etc., and achieve the effect of strong anti-pollution ability, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

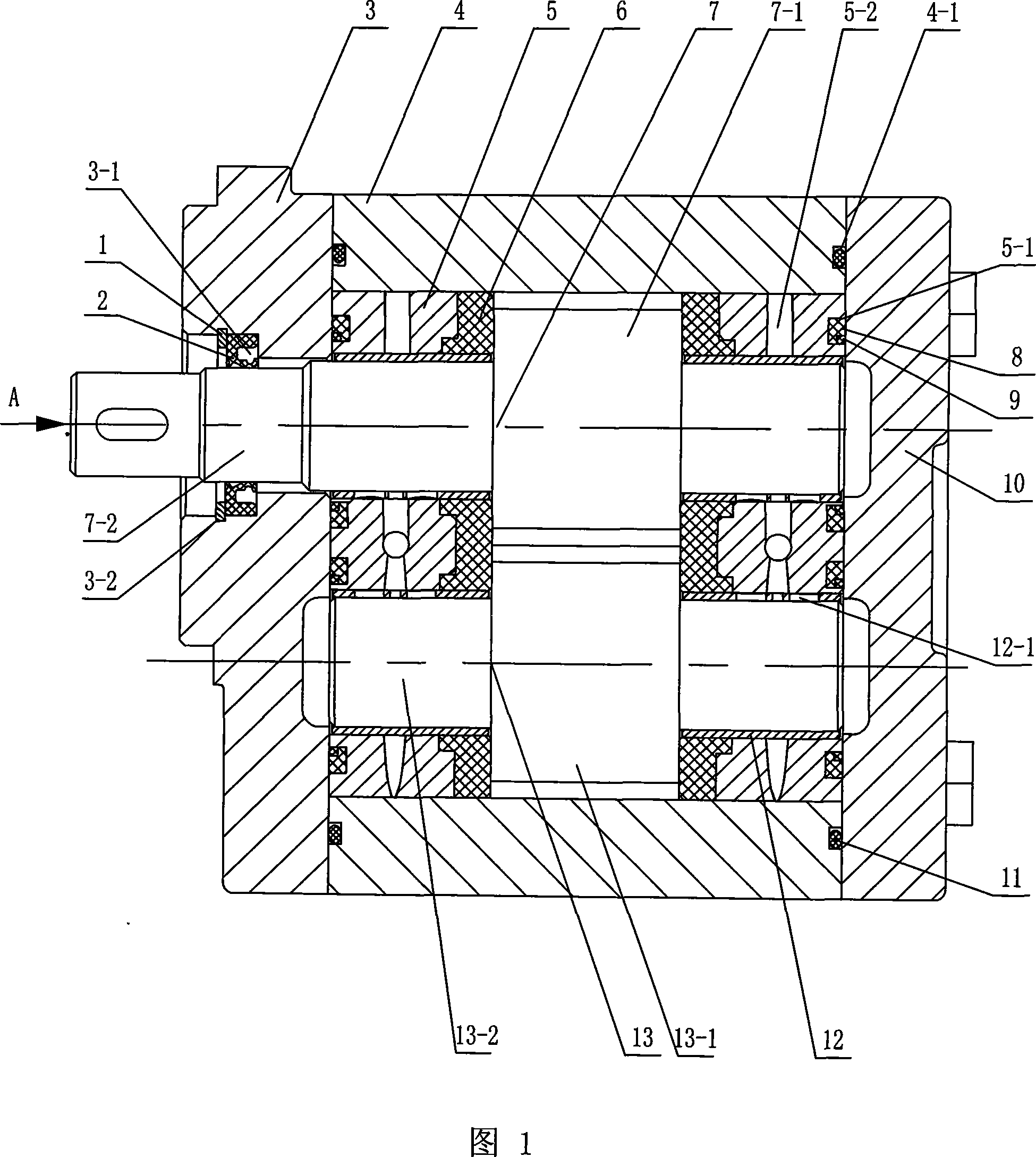

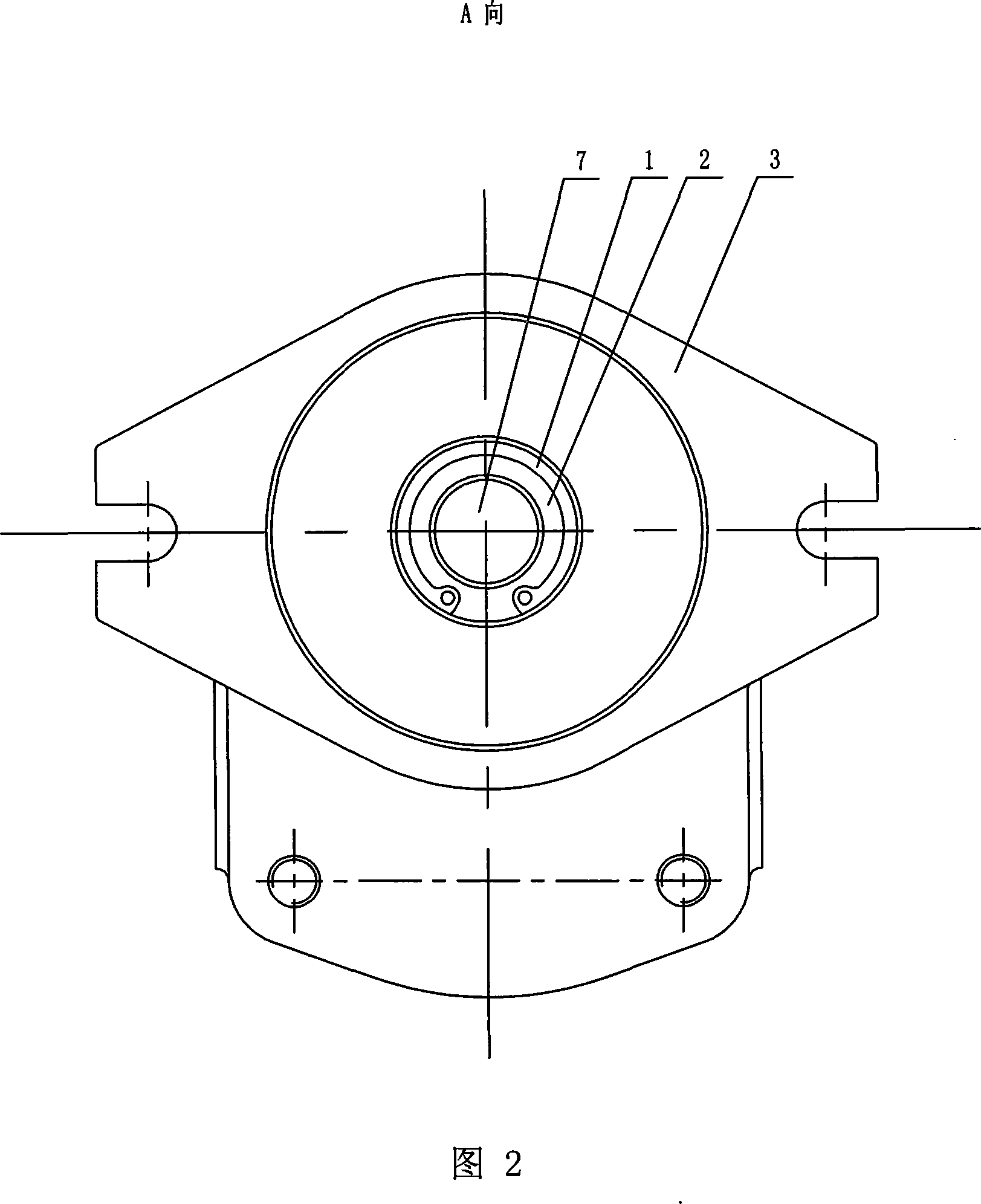

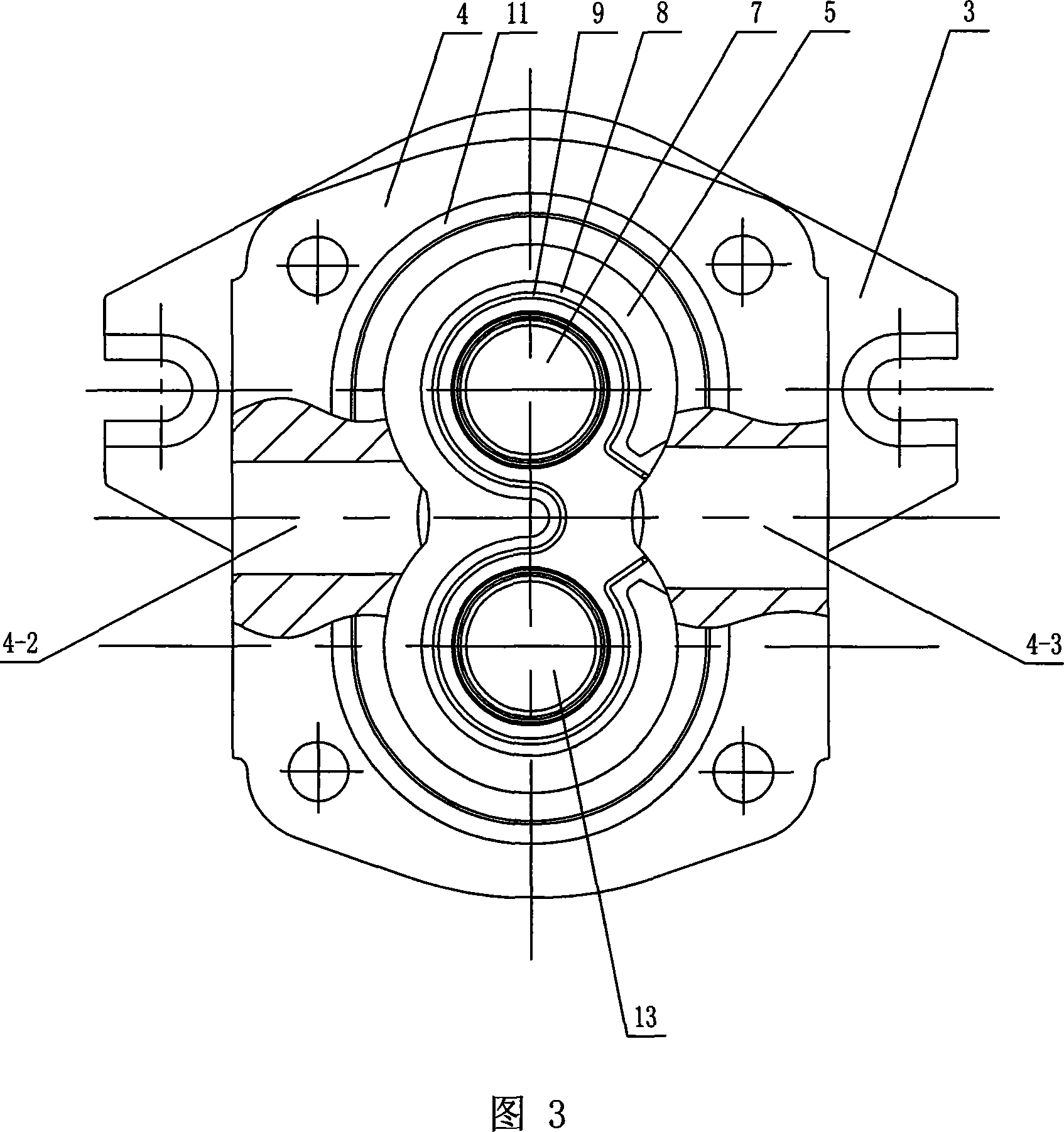

[0007] Specific embodiment 1: This embodiment is described in conjunction with Fig. 1 to Fig. 14. This embodiment consists of a spring retaining ring 1, a shaft sealing ring 2, a front end cover 3, a housing 4, a floating bushing 5, a side plate 6, and a driving gear Shaft 7, floating sleeve sealing ring 8, sealing ring bracket 9, rear end cover 10, housing sealing ring 11, sliding bearing 12 and driven gear shaft 13, the front end face of the housing 4 is equipped with a front end cover 3. A rear end cover 10 is installed on the rear end surface of the housing 4, and an annular groove 4-1 is respectively opened on the joint surface of the housing 4, the front end cover 3 and the rear end cover 10, and the sealing ring of the housing 11 is installed in the annular groove 4-1, and the left and right side walls of the housing 4 are respectively provided with a water inlet hole 4-2 and a water outlet hole 4-3, and the shoulder hole 3-1 of the front end cover 3 A shaft sealing rin...

specific Embodiment approach 2

[0008] Specific Embodiment 2: This embodiment is described with reference to FIG. 1 . In this embodiment, a hydraulic radial force balance hole 5-2 is opened on the floating bushing 5 . Such a setting can make the radial force tend to be in a balanced state. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific Embodiment 3: This embodiment is described with reference to FIG. 1 and FIG. 13 . The sliding bearing 12 of this embodiment is provided with a lubricating hole 12 - 1 . Such setting increases the lubrication of the sliding bearing. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com