Non-earth grass blanket preparation based on sludge compositing

A production method, soilless grass technology, applied in soilless cultivation, preparation of organic fertilizers, botanical equipment and methods, etc., can solve problems that have not yet entered the stage of practical application, achieve convenient management, wide application range, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The content of the present invention will be further described below through specific embodiments:

[0027] The stacking site is a concrete structure, with a plastic film rainproof roof above the site. The ground is laid with "Feng"-shaped PVC ventilation pipes, and there are small holes around the ventilation pipes. One end of the ventilation pipe is sealed, and the other end is connected with the blower.

[0028] The sludge used in this example is digested and dewatered sludge from Liede Sewage Treatment Plant in Guangzhou City. About 60% (the most intuitive judgment is "the hand holds the compost material tightly, there are water marks, but the water drops do not drip out" is the degree), pile it up and cover the surface with plastic film. Oxygen is supplied to the sludge pile by the gap forced ventilation method, and the ventilation frequency is 0.50m 3 / (t min), ventilate for 30 minutes every 3 hours.

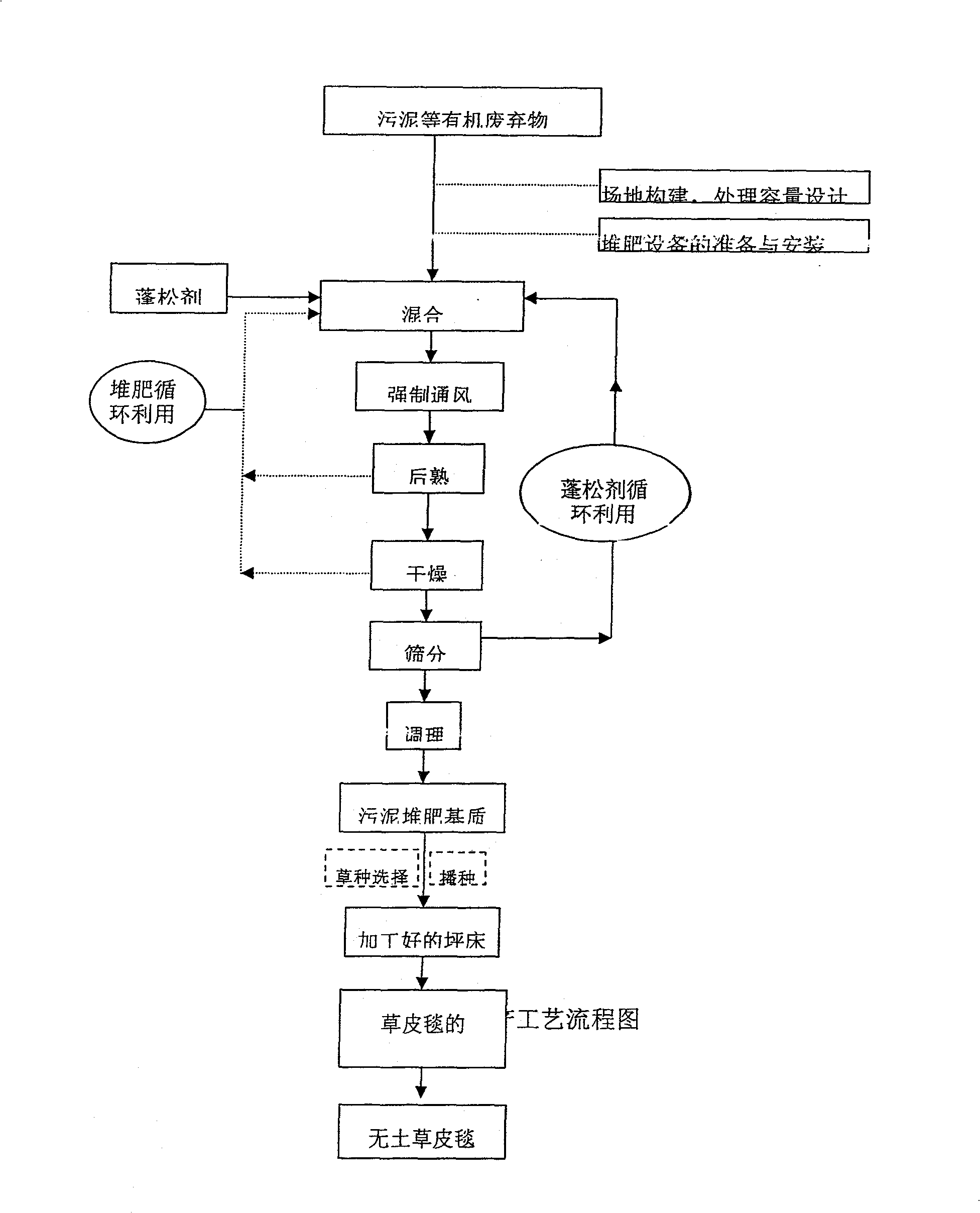

[0029] Please refer to the operation process of this examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com