Laser beam focusing integral form paraboloidal mirror

A technology of parabolic mirror and laser beam, which is applied in the direction of condenser, laser welding equipment, optics, etc. It can solve the problems of unfavorable laser material uniformity, easy degradation of adhesive, and difficult heat dissipation of adhesive, so as to improve the focusing quality and improve the The ability and heat dissipation ability, the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

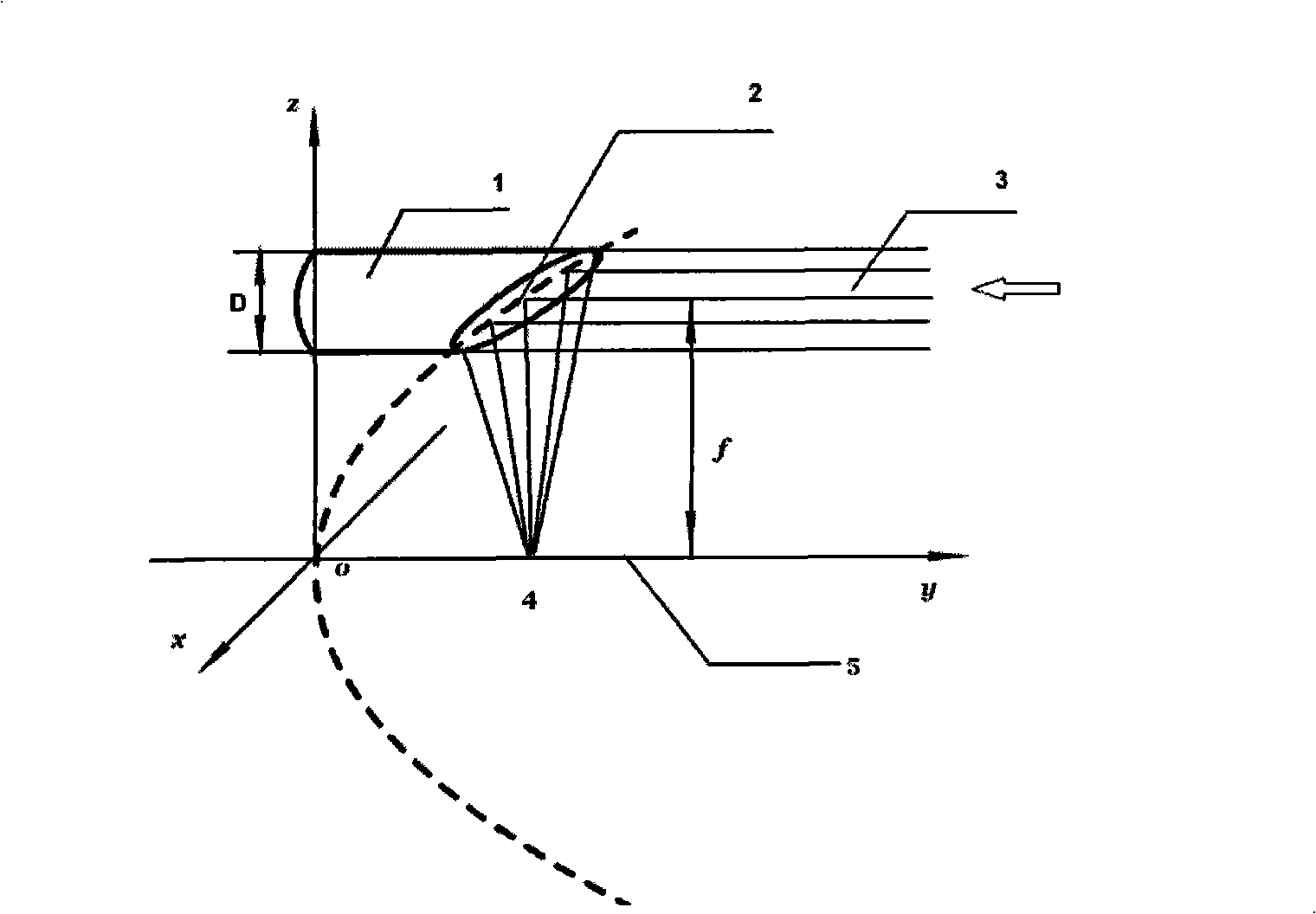

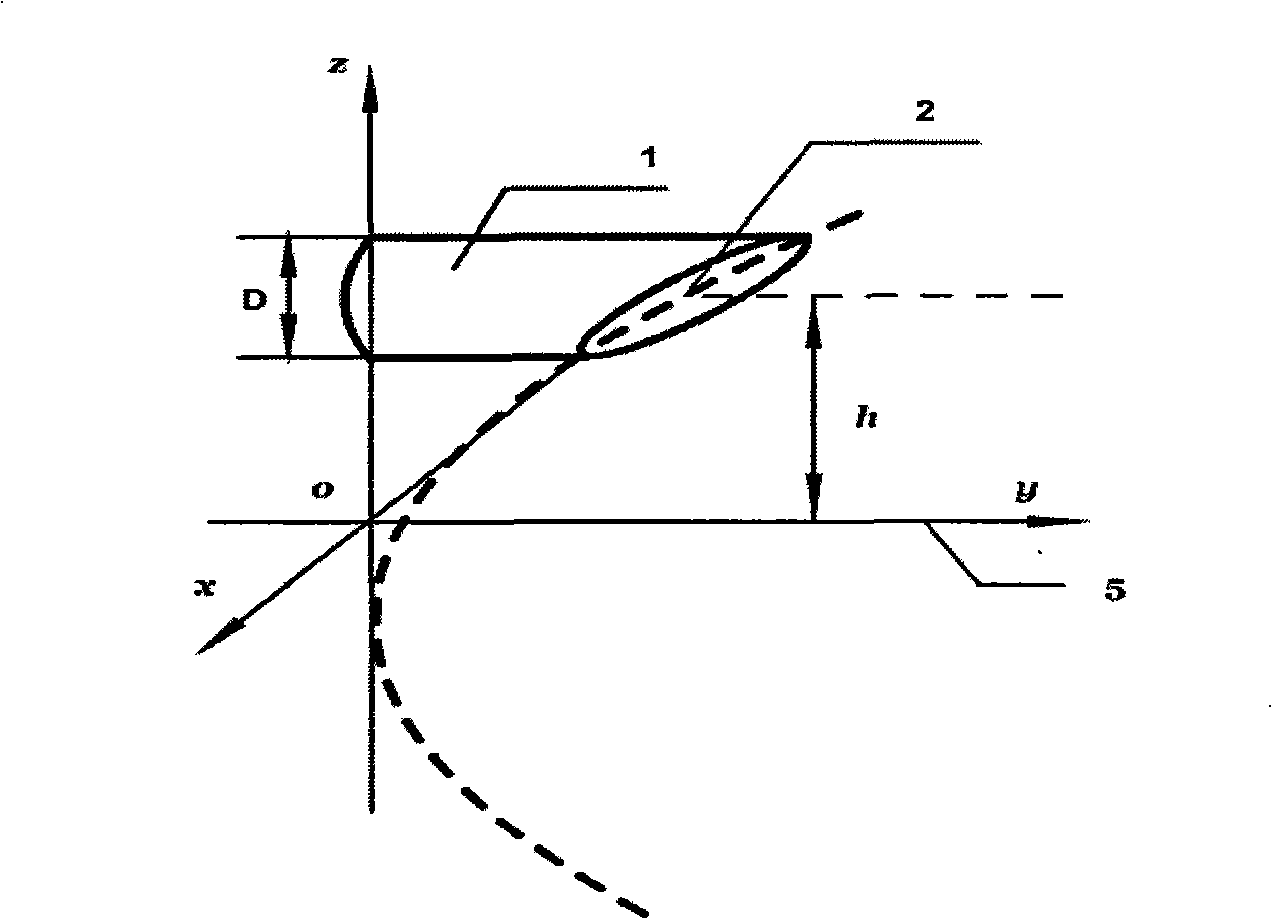

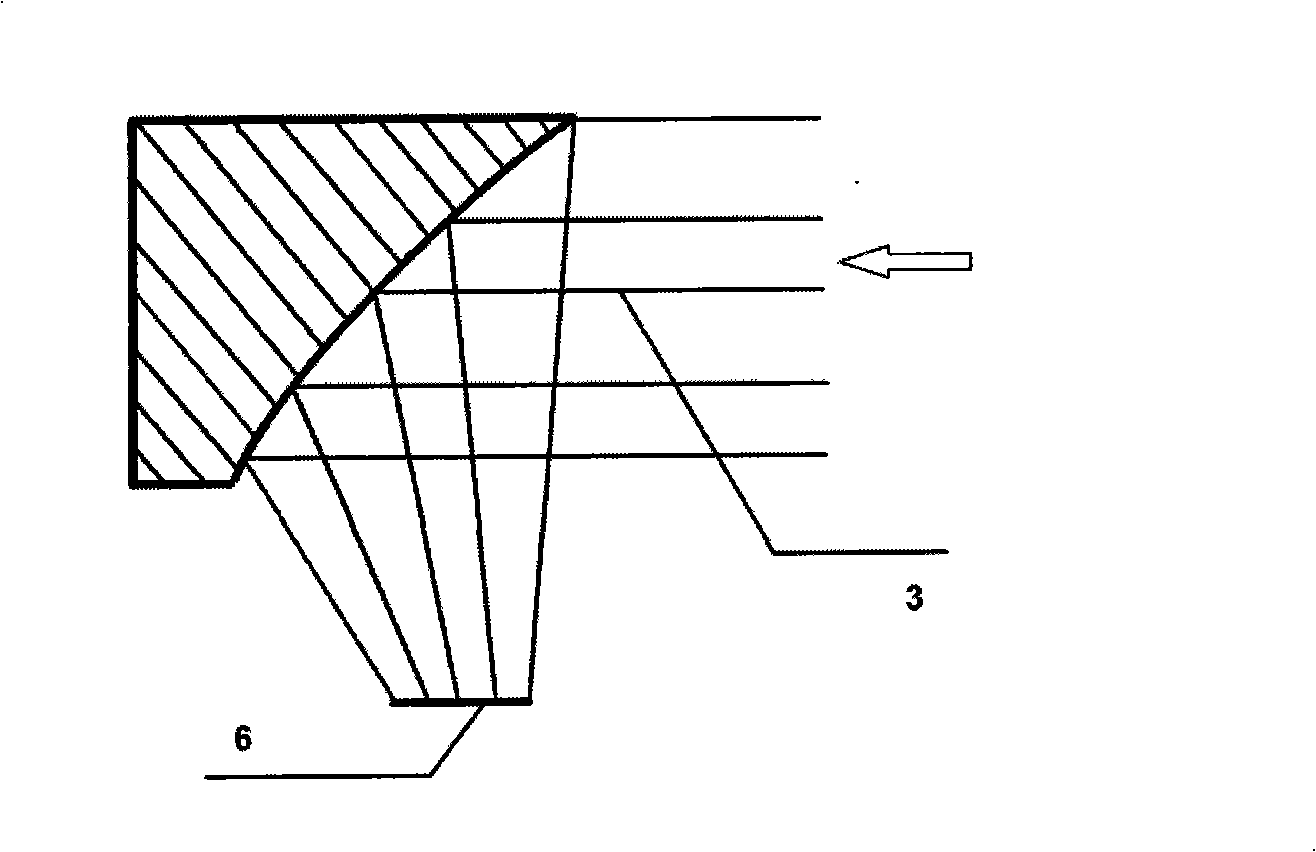

[0014] A standard parabolic reflective focusing mirror in the prior art is as figure 1 As shown, the parallel light beam 3 incident on the parabolic mirror surface is all focused on the focal point 4, and the paraboloid equation of the mirror surface is y = x 2 + z 2 2 f , Among them, f is the focal length of the parabolic mirror. The method of making a standard parabolic reflector is as follows: place the substrate 1 on the disc of a high-precision lathe, control the distance between the center 2 of the processing surface of the substrate and the axis 5 of the lathe to be f, and the turning tool follows the parabolic equation under the control of the numerical control system y = z 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com