Defect correction method and manufacturing method for grey level mask and grey level mask

A grayscale mask and defect technology, which is applied to the photolithographic process of pattern surface, the original used for photomechanical processing, and the exposure device of photolithographic process, can solve the problem of small light transmission and improve the controllability , stable and proper correction, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

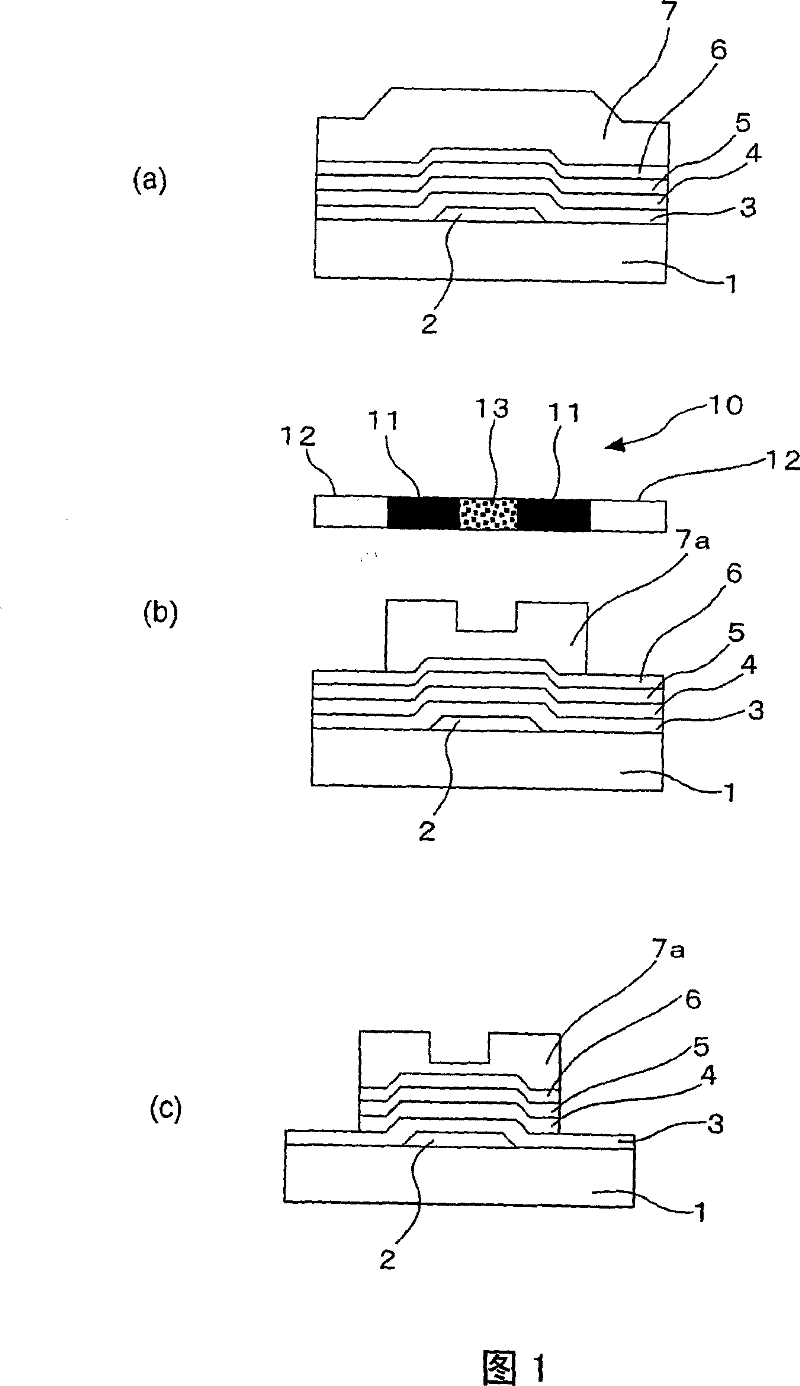

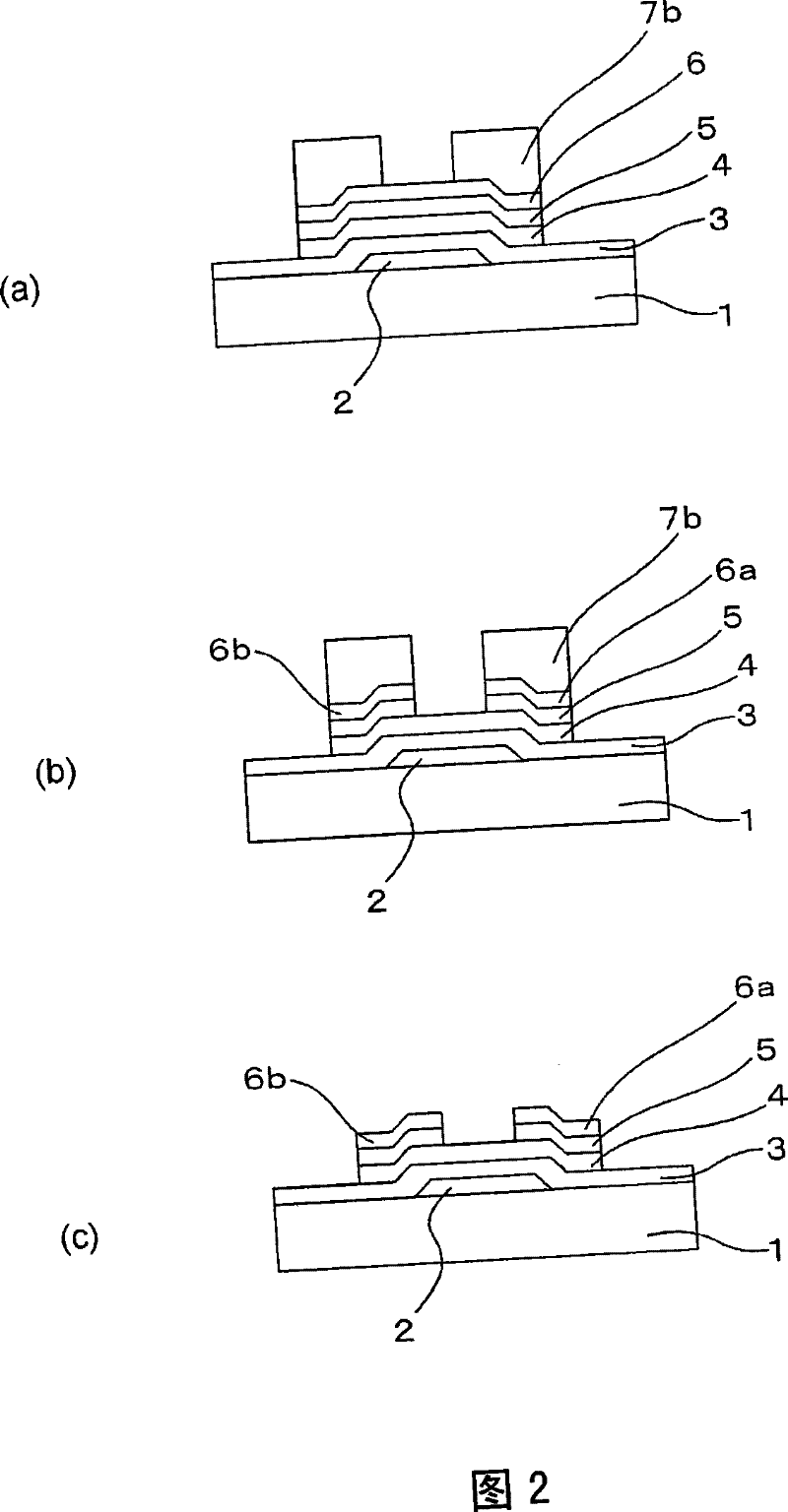

[0059] Figure 8 (a)~ Figure 8 (d) shows the first embodiment of the defect correction method of the gray scale mask related to the present invention, Figure 8 (a)~ Figure 8 (c) are perspective views illustrating a defect correction method in order of steps, respectively, Figure 8 (d) is Figure 8 Side sectional view along line L-L in (c). in addition, Figure 9 It is a sectional view for explaining the pattern transfer method using the gray scale mask of this invention. and, Figure 9 The corrected defective portion is not shown.

[0060] Figure 9 The grayscale mask 20 of the present invention shown is used to manufacture thin film transistors (TFT) or color filters of liquid crystal display devices (LCD), or plasma display panels (PDP), etc., and is formed on the transferred body 30. The resist pattern 33 having a stepwise or continuous film thickness. in addition, Figure 9 Symbols 32A and 32B in , represent films laminated on the substrate 31 in the body to...

no. 2 approach

[0086] Figure 11 (a)~ Figure 11 (d) shows the second embodiment of the defect correction method of the grayscale mask related to the present invention, Figure 11 (a)~ Figure 11 (c) is a perspective view illustrating each defect correction method in order of steps, Figure 11 (d) is Figure 11 Side sectional view along line L-L in (c).

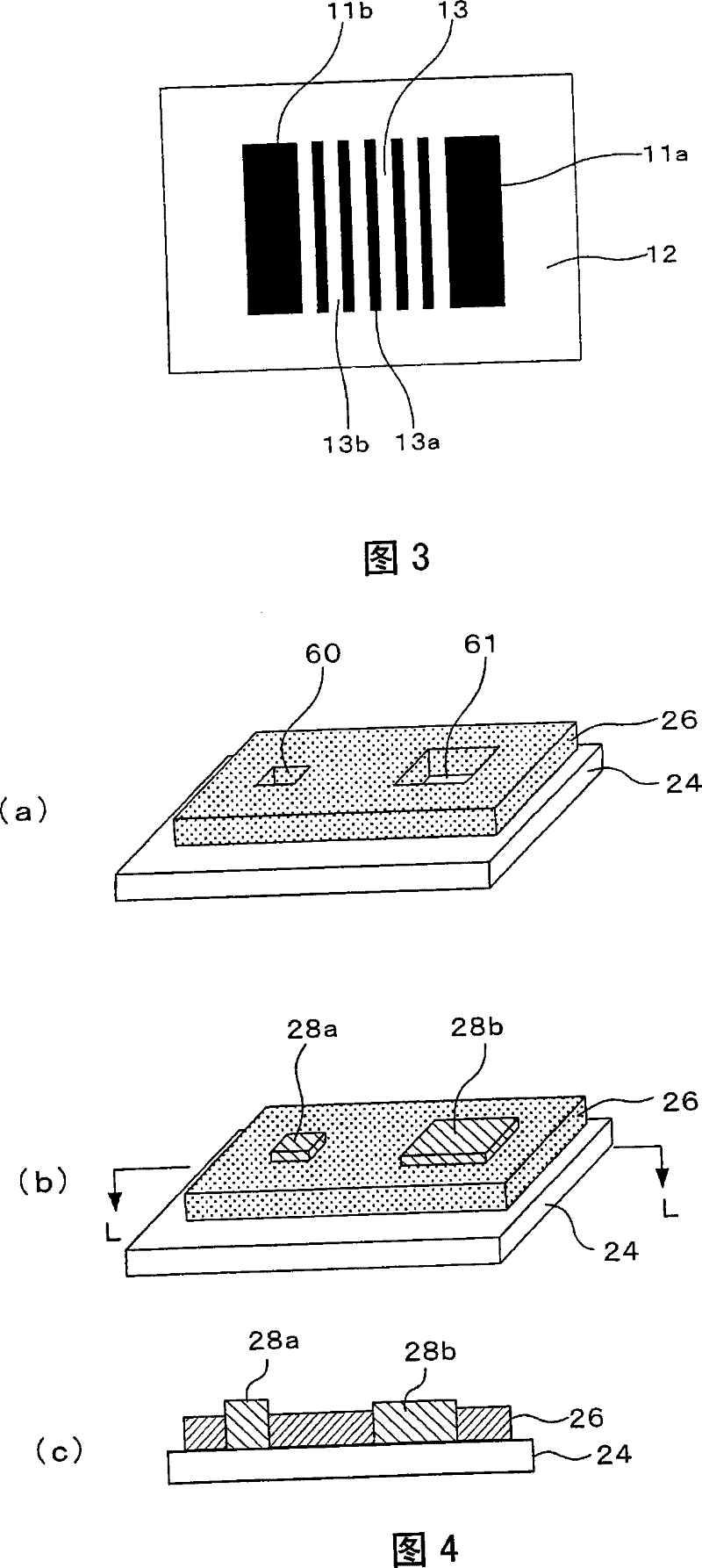

[0087] Figure 6 (a)~ Figure 6 As also explained in (c), the actual white defect does not necessarily have a shape in which the cross section is substantially perpendicular to the film thickness direction. For example Figure 11 As shown in (a), sometimes a white defect 52 is formed in the light semi-transmissive film 26, and the defect is shaped like a mortar, and the cross-section gradually becomes narrower toward the transparent substrate 24 side. At this time, if a correction film with a uniform film thickness is formed on the defect site, the correction film is formed on the half-transmissive film 26 which remains partly in th...

no. 3 approach

[0092] Figure 12 (a), Figure 12 (b) shows the third embodiment of the defect correction method of the grayscale mask according to the present invention, and is a perspective view illustrating the defect correction method in order of steps.

[0093] When the size of the white defect generated in the semi-transparent portion of the grayscale mask exceeds a certain area, for example, when the film formation area of the correction film is determined in the same way as in the first embodiment, the area that is an integral multiple of the certain area is defined as Defect correction area.

[0094] First, in the third embodiment, when using a film-forming apparatus and a film-forming material determined in the same manner as in the first embodiment, the film-forming area of the correction film is determined so as to achieve a constant exposure light transmission amount.

[0095] Then, when the size of the white defect generated in the semi-transparent part exceeds the above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com