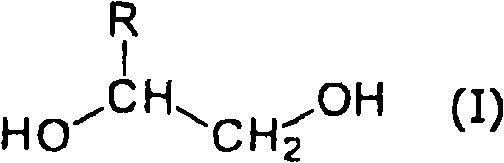

Polyester of terephthalic acid, method for the production thereof, and use of the same

A technology of terephthalic acid and polyester, applied in the direction of one-component copolyester rayon filament, etc., can solve the problems of unrealized constant yarn quality level and high cost, and achieve low by-products/decomposition products, cost Beneficial, lower melting temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Embodiment: adopt 10mol% 1, the modification of 2-butanediol

[0032] 12,126 g dimethyl terephthalate (62.44 mol), 7,848.8 g ethylene glycol (126.45 mol) and 1,266.22 g 1,2-butanediol were placed in a 20-liter stainless steel reactor at Mn(OAc) 2 4H 2 Catalyzed by O, transesterification was performed under methanol dissociation in a conventional manner, and the formed copolyester was prepared on Sb 2 o 3 Catalyzed polycondensation to form copolyesters. The reaction can be carried out here at 260°C.

[0033] DSC measurements were performed in the temperature range of 30-300° C. with a heating rate of 10 K / min under nitrogen atmosphere.

[0034] The polyester is conventionally spun into fibers by melt spinning. Very good spinnability of 3000-6000 m / min has been shown.

[0035] Table 1 below shows the effect of modification on melting temperature and spinning temperature.

[0036] Table 1:

[0037] unmodified polyester

10% 1,2-butanediol modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com