Bendable organic small molecule touch sensor array and method for making same

A tactile sensor, small molecule technology, applied in the field of sensors, can solve the problems of difficulty, heavy weight, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

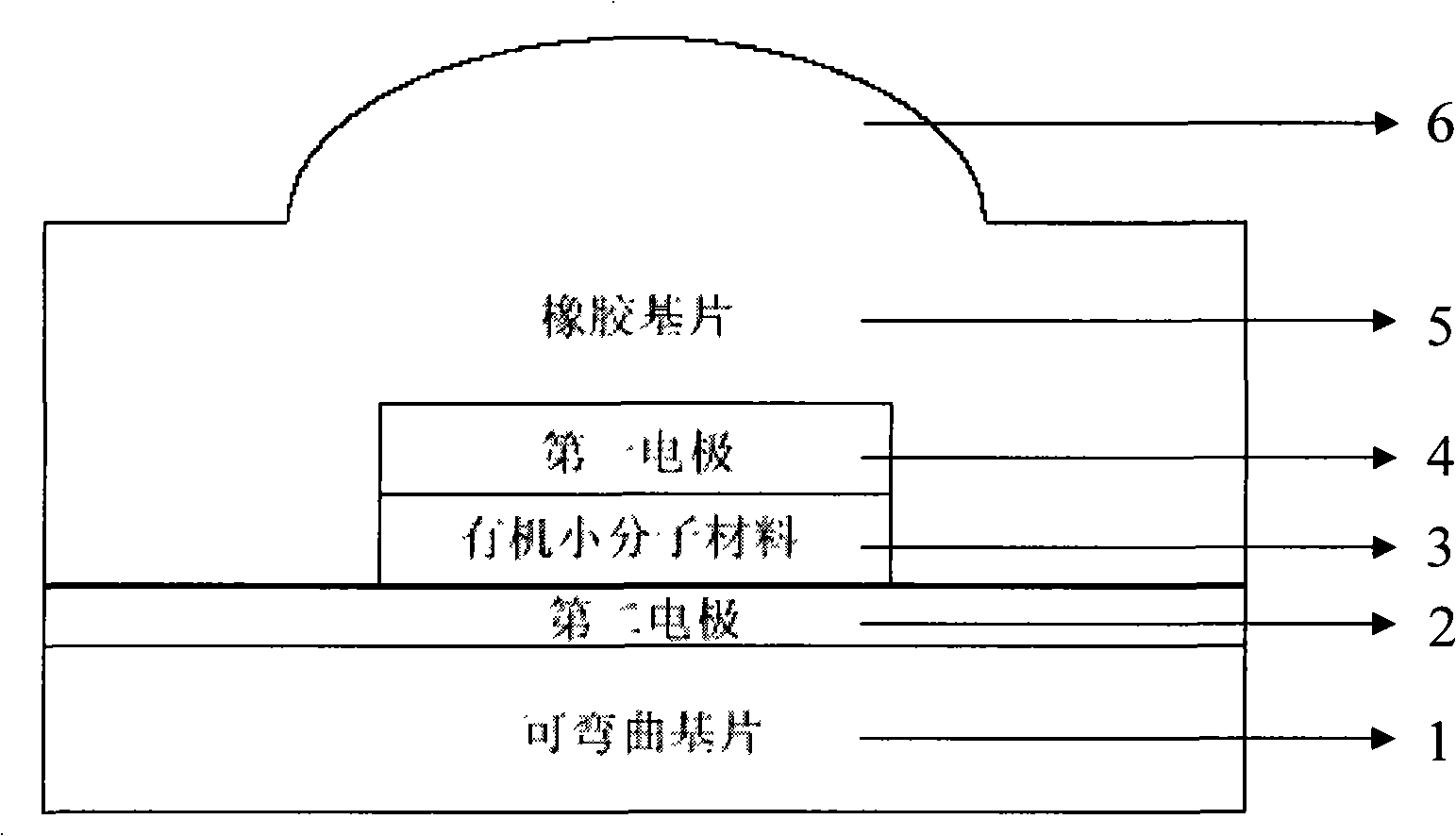

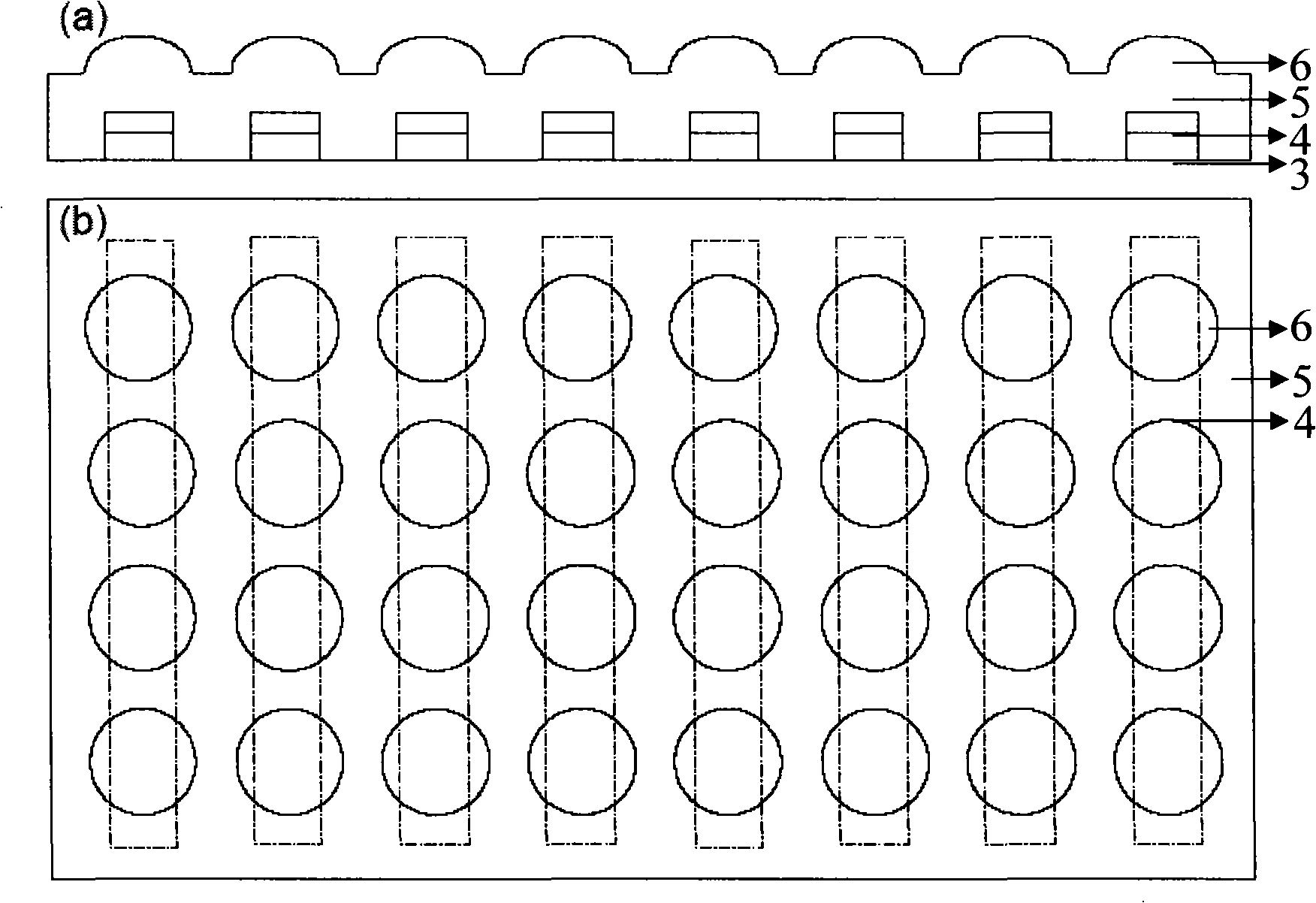

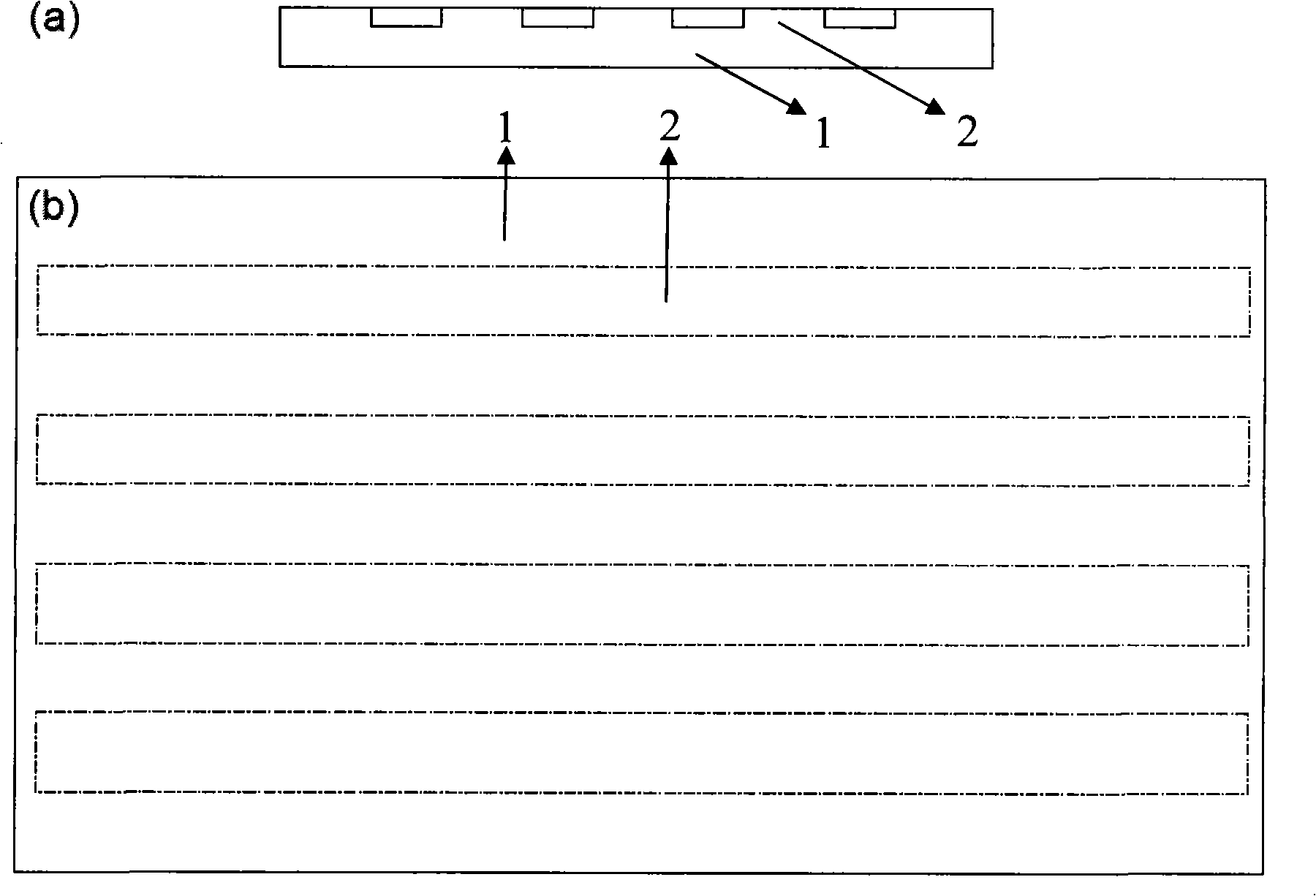

[0019] Take the polyimide substrate on which the ITO thin film has been deposited, and the stripe width of the ITO used as the second electrode (anode) is 0.5 mm. Prepare the Alq thin film that thickness is 100nm by vacuum evaporation, and each Alq spot is the circle of diameter 0.707mm, then on Alq, evaporate the Al metal stripe that width is 0.5mm, form the first electrode (cathode), thus just prepare The unit size is 1×1mm 2 The sensor dot matrix forms a 20×40 pressure sensor array. On the prepared pressure sensor array, cover Figure 4 As shown, there is rubber with a thickness of 0.5-2 mm with protrusions, and the protrusions are aligned with the pressure unit, and then the device is encapsulated with epoxy resin and ultraviolet or heating methods. The encapsulation process is carried out in an anhydrous and oxygen-free high-purity inert environment. After packaging, the pressure sensor array can be connected to a special external analysis circuit, and the pressure tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com