2-dimensional marking device and marking method for digital aviation measuring camera

A technology for aerial survey cameras and calibration devices, which is applied in image data processing, instruments, calculations, etc., and can solve the problems that the distortion measurement of the whole camera is not applicable, and the measurement device of the collimator group method is complicated and unsuitable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

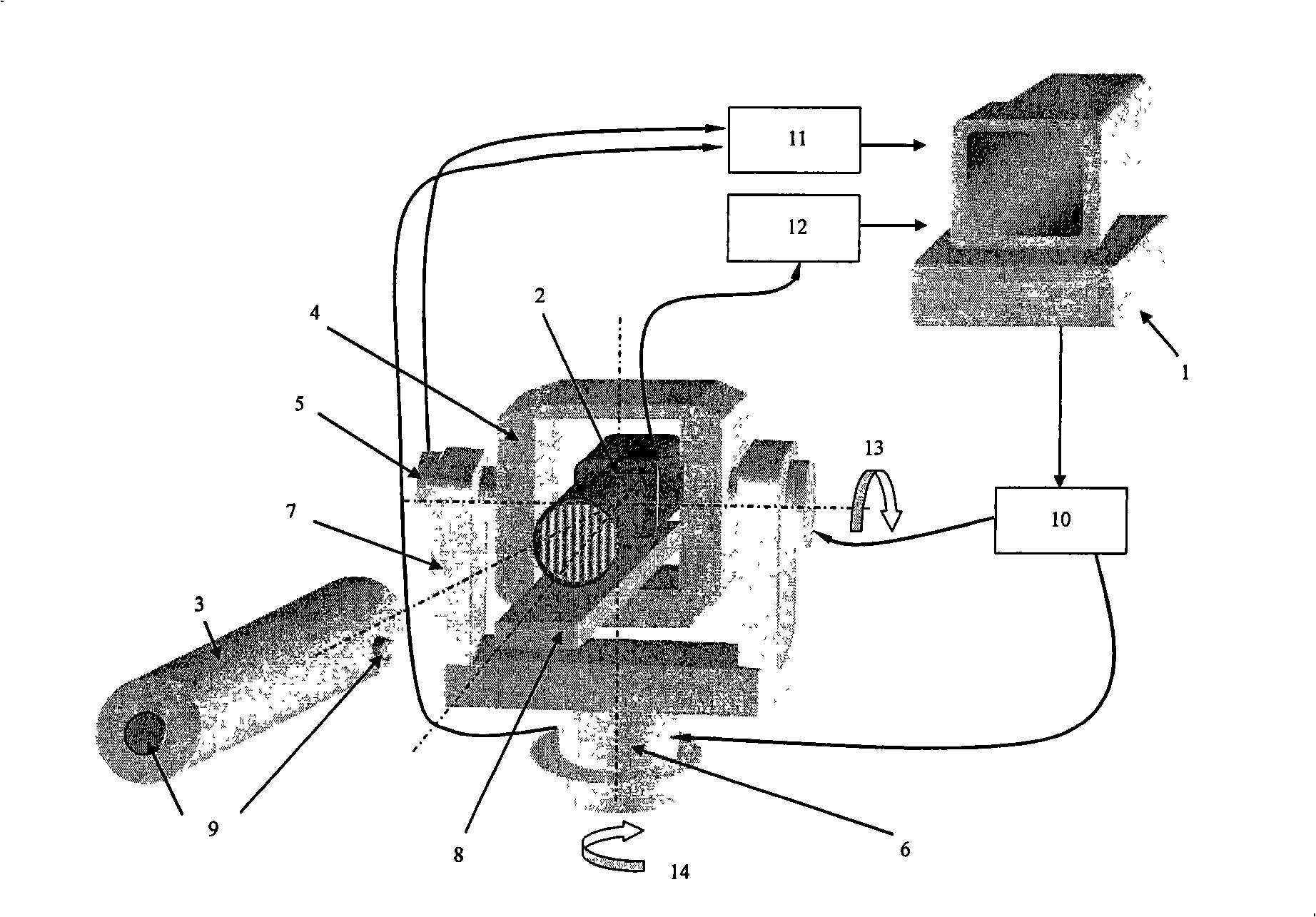

[0027] Such as figure 1 As shown, the present invention is mainly composed of an inner azimuth, a computer 1, a measured aerial survey camera 2 and a collimator 3. The internal azimuth instrument is mainly composed of the fixed frame 4 of the system under test, the pitch axis 5, the azimuth axis 6 and the two-axis turntable 7. The two-axis turntable 7 is designed with a high-precision encoder inside, and the fixed frame 4 of the system under test is connected with the pitch axis 5. It can rotate synchronously with the pitch axis 5, and the two-axis turntable 7 is closely connected with the azimuth axis 6 in addition to being connected with the pitch axis 5. The rotation of the azimuth axis 6 can drive the two-axis turntable 7 and the pitch axis 5 to rotate in the horizontal direction at the same time; The measurement direction range 13 of the pitch angle of the azimuth is ±35°, and the measurement direction range 14 of the azimuth angle is ±45°. The aerial survey camera 2 und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com