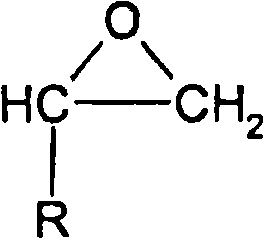

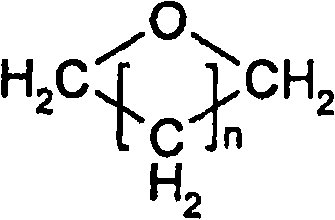

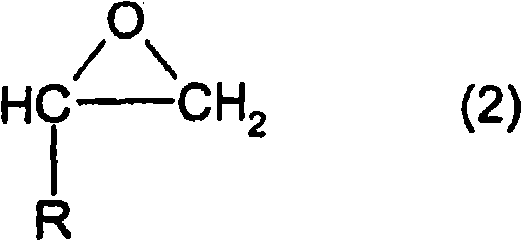

Method for producing alkylene glycol diethers

A technology of alkylene glycol diether and alkyl, which is applied in the field of preparing chain alkylene glycol diether, and can solve problems such as difficult sales

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0070] Example 4: HBF 4 / H 2 SO 4 catalytic

[0071] Similar to Comparative Example 1, 200 mg (2.28 mmol) of fluoroboric acid, 231 mg (2.28 mmol) of sulfuric acid and 157 g (3.41 mol) of dimethyl ether were initially charged in a 1-liter steel autoclave, and heated at 55° C. and 15 bar, 15.0 g (0.34 mol) of ethylene oxide were added. After an after-reaction time of 50 minutes and draining of the dimethyl ether, 30.7 g of residue were isolated. This residue has the following composition:

[0072] 59.9% Ethylene glycol dimethyl ether

[0073] 2.1% 1,4-dioxane

[0074] 6.8% Ethylene glycol monomethyl ether

[0075] 17.8% diglyme

[0076] 3.0% Diethylene glycol monomethyl ether

[0077] 4.3% Triglyme

[0078] 0.7% triethylene glycol monomethyl ether

[0079] 1.2% Tetraglyme

[0080] 0.3% Pentaethylene glycol dimethyl ether

[0081] 3.9% Unknown

Embodiment 5

[0082] Example 5: HBF 4 / H 3 PO 4 catalytic

[0083] Similar to Comparative Example 1, 200 mg (2.28 mmol) of fluoroboric acid, 223 mg (2.28 mmol) of phosphoric acid and 157 g (3.41 mol) of dimethyl ether were initially charged in a 1 liter steel autoclave, and heated at 55° C. and 15 bar, 15.0 g (0.34 mol) of ethylene oxide were added. After an after-reaction time of 50 minutes and draining of the dimethyl ether, 23.8 g of residue were isolated. This residue has the following composition:

[0084] 60.1% Ethylene glycol dimethyl ether

[0085] 1.7% 1,4-dioxane

[0086] 5.0% Ethylene glycol monomethyl ether

[0087] 16.9% diglyme

[0088] 4.6% Diethylene glycol monomethyl ether

[0089] 3.8% Triglyme

[0090] 1.6% triethylene glycol monomethyl ether

[0091] 0.9% Tetraglyme

[0092] 1.4% tetraethylene glycol monomethyl ether

[0093] 0.1% Pentaethylene glycol dimethyl ether

[0094] 3.9% Unknown

Embodiment 6

[0095] Example 6: HBF 4 / HNO 3 catalytic

[0096] Similar to Comparative Example 1, 200 mg (2.28 mmol) of fluoroboric acid, 288 mg (2.96 mmol) of nitric acid and 157 g (3.41 mol) of dimethyl ether were initially charged in a 1 liter steel autoclave, and heated at 55° C. and 15 bar, 15.0 g (0.34 mol) of ethylene oxide were added. After an after-reaction time of 50 minutes and draining of the dimethyl ether, 29.7 g of residue were isolated. This residue has the following composition:

[0097] 59.8% Ethylene glycol dimethyl ether

[0098] 1.8% 1,4-dioxane

[0099] 3.0% Ethylene glycol monomethyl ether

[0100] 16.3% diglyme

[0101] 4.3% Diethylene glycol monomethyl ether

[0102] 3.8% Triglyme

[0103] 1.9% triethylene glycol monomethyl ether

[0104] 3.2% tetraglyme

[0105] 1.1% tetraethylene glycol monomethyl ether

[0106] 0.3% Pentaethylene glycol dimethyl ether

[0107] 4.5% Unknown

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com