Defoaming agent used for methyl-ethyl ketone butylenes purification concentration process

A technology of acetone butene and defoamer, which is applied in the field of chemical additives, refining and chemical production additives - butene concentration defoamer, to ensure temperature resistance and chemical stability, and reduce foam surface energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

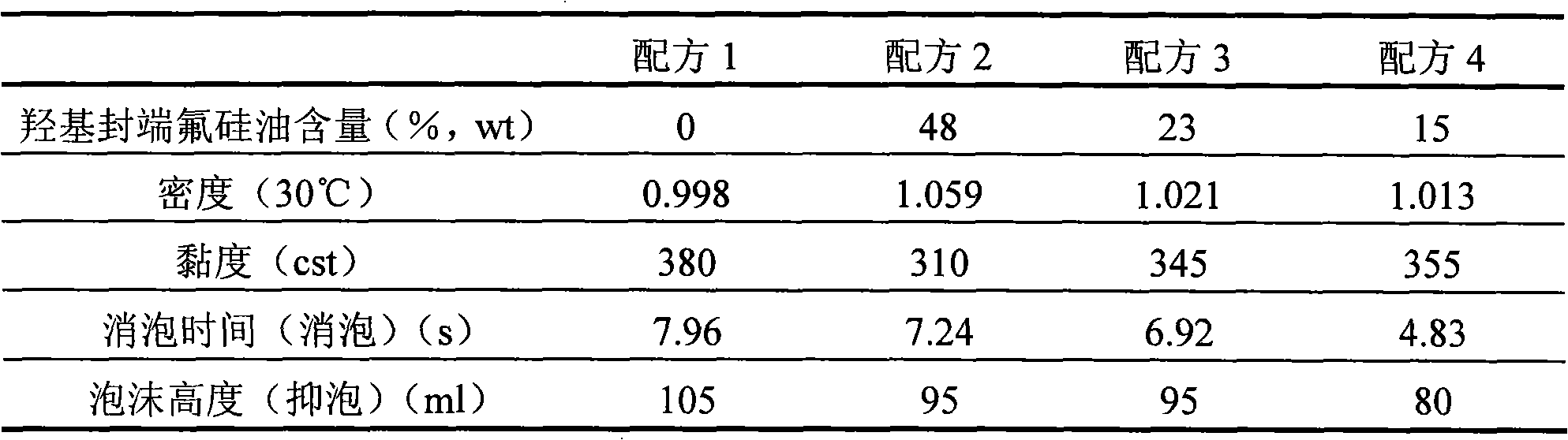

Embodiment 1

[0042] Component formula: by weight percentage.

[0043] Methyl silicone oil 100cs 50.0%;

[0044] Methyl silicone oil 1000cs 25.0%;

[0045] Hydroxyl-terminated fluorosilicone oil 23.0%;

[0046] Vapor phase hydrophobic white carbon black 1.9%;

[0048] Preparation Process:

[0049] a. Accurately weigh each component, put it into the batching kettle, and lower the lid of the kettle.

[0050] b. Start the stirring paddle, gradually increase the speed, control at 500r / min and stir for 15 minutes; start the disperser, gradually increase the speed, keep it at 800r / min, and disperse for 20 minutes.

[0051] c. Keep the rotation speed of the agitator constant, and gradually close the disperser from fast to slow; start the homogenizer, from slow to fast, and finally control it at 2000r / min, and homogenize for 10 minutes.

[0052] d. Keep the rotation speed of the agitator constant, and gradually close the homogenizer from fast to slow; start the...

Embodiment 2

[0059] Component formula: by weight percentage.

[0060] Methyl silicone oil 100cs 70.0%;

[0061] Methyl silicone oil 1000cs 12.0%

[0062] Group-terminated fluorosilicone oil 15.0%;

[0063] Vapor-phase hydrophobic silica 2.9%;

[0065] Preparation Process:

[0066] a. Accurately weigh each component, put it into the batching kettle, and lower the lid of the kettle.

[0067] b. Start the stirring paddle, gradually increase the speed, control at 300r / min and stir for 20 minutes; start the disperser, gradually increase the speed, keep it at 800r / min, and disperse for 20 minutes.

[0068] c. Keep the rotation speed of the agitator constant, and gradually close the disperser from fast to slow; start the homogenizer, from slow to fast, and finally control it at 1800r / min, and homogenize for 10 minutes.

[0069] d. Keep the rotation speed of the agitator constant, and gradually close the homogenizer from fast to slow; start the disperser, from s...

Embodiment 3

[0076] Component formula: by weight percentage.

[0077] Methyl silicone oil 100cs 63.0%;

[0078] Methyl silicone oil 1000cs 20.0%;

[0079] Group-terminated fluorosilicone oil 15.0%;

[0080] Vapor phase hydrophobic white carbon black 1.9%;

[0082] Preparation Process:

[0083] a. Accurately weigh each component, put it into the batching kettle, and lower the lid of the kettle.

[0084] b. Start the stirring paddle, gradually increase the speed, control at 400r / min and stir for 15 minutes; start the disperser, gradually increase the speed, keep it at 900r / min, and disperse for 15 minutes.

[0085] c. Keep the rotation speed of the agitator constant, and gradually close the disperser from fast to slow; start the homogenizer, from slow to fast, and finally control it at 1800r / min, and homogenize for 10 minutes.

[0086] d. Keep the rotation speed of the agitator constant, and gradually close the homogenizer from fast to slow; start the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com