Blast furnace top dust-collecting equipment

A technology of dust removal device and blast furnace, which is applied in the direction of dust collector, etc., can solve the problems of high recycling cost, easy dust accumulation, long dust removal pipeline, etc., and achieve the effect of simple structure, energy saving and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

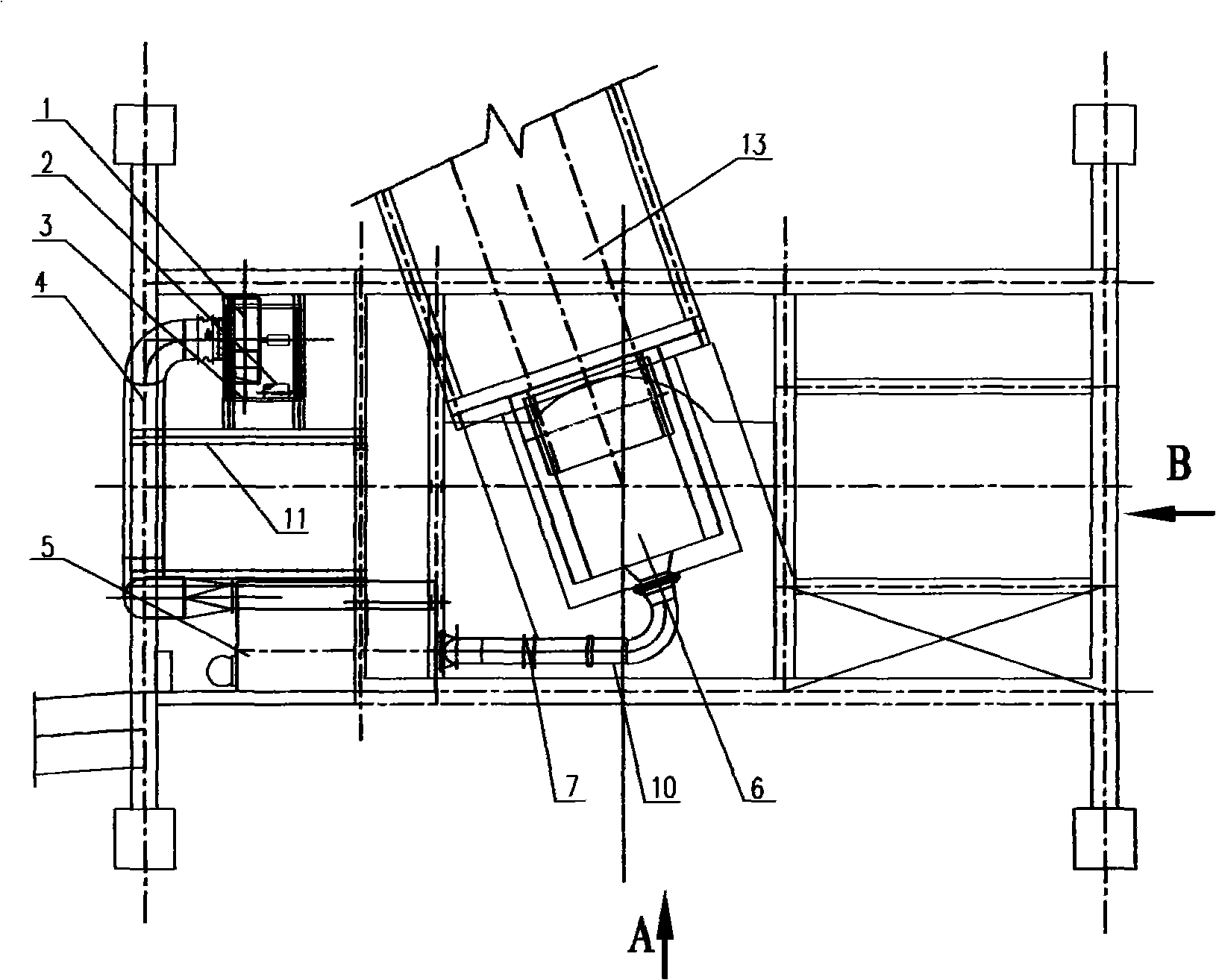

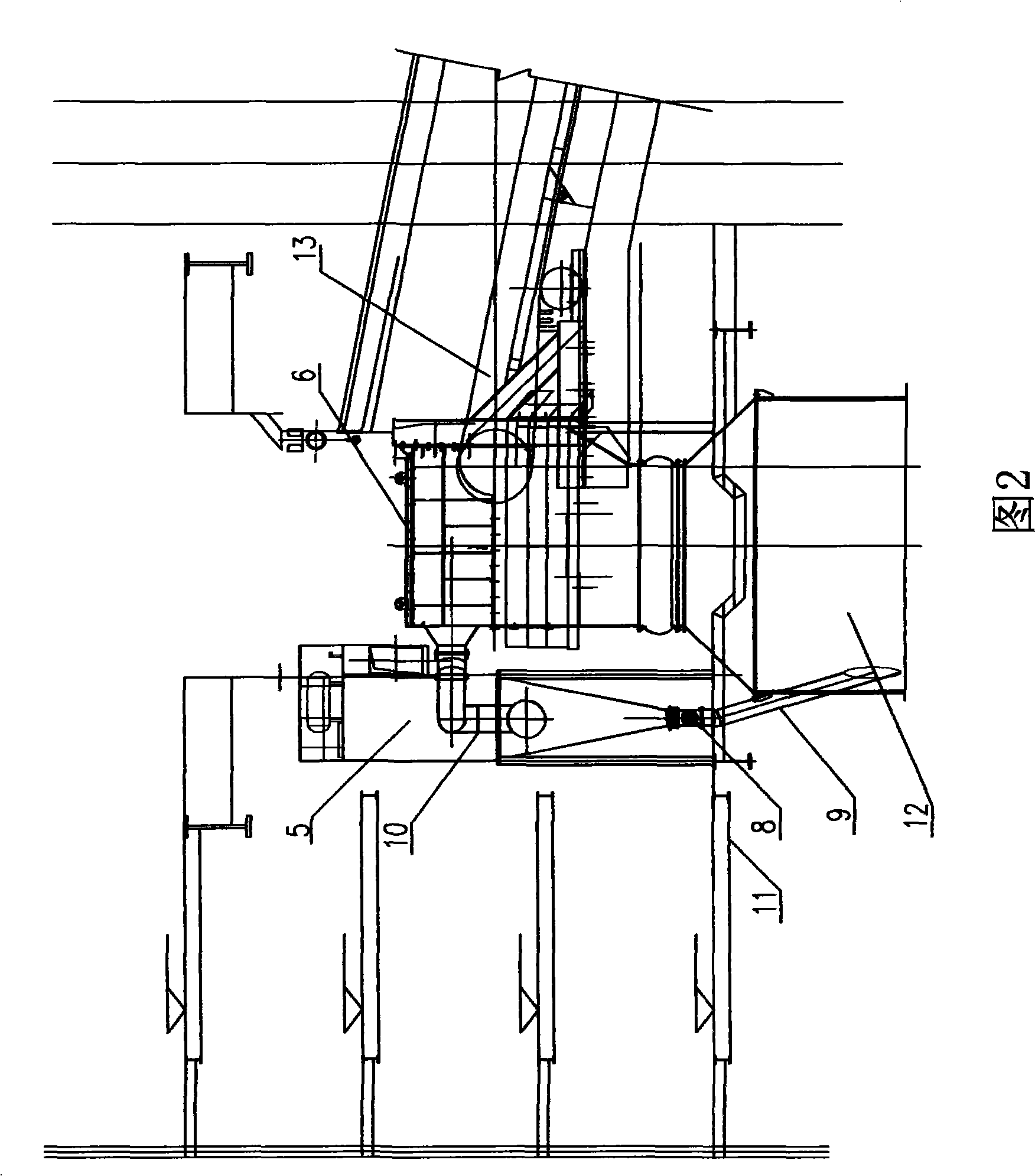

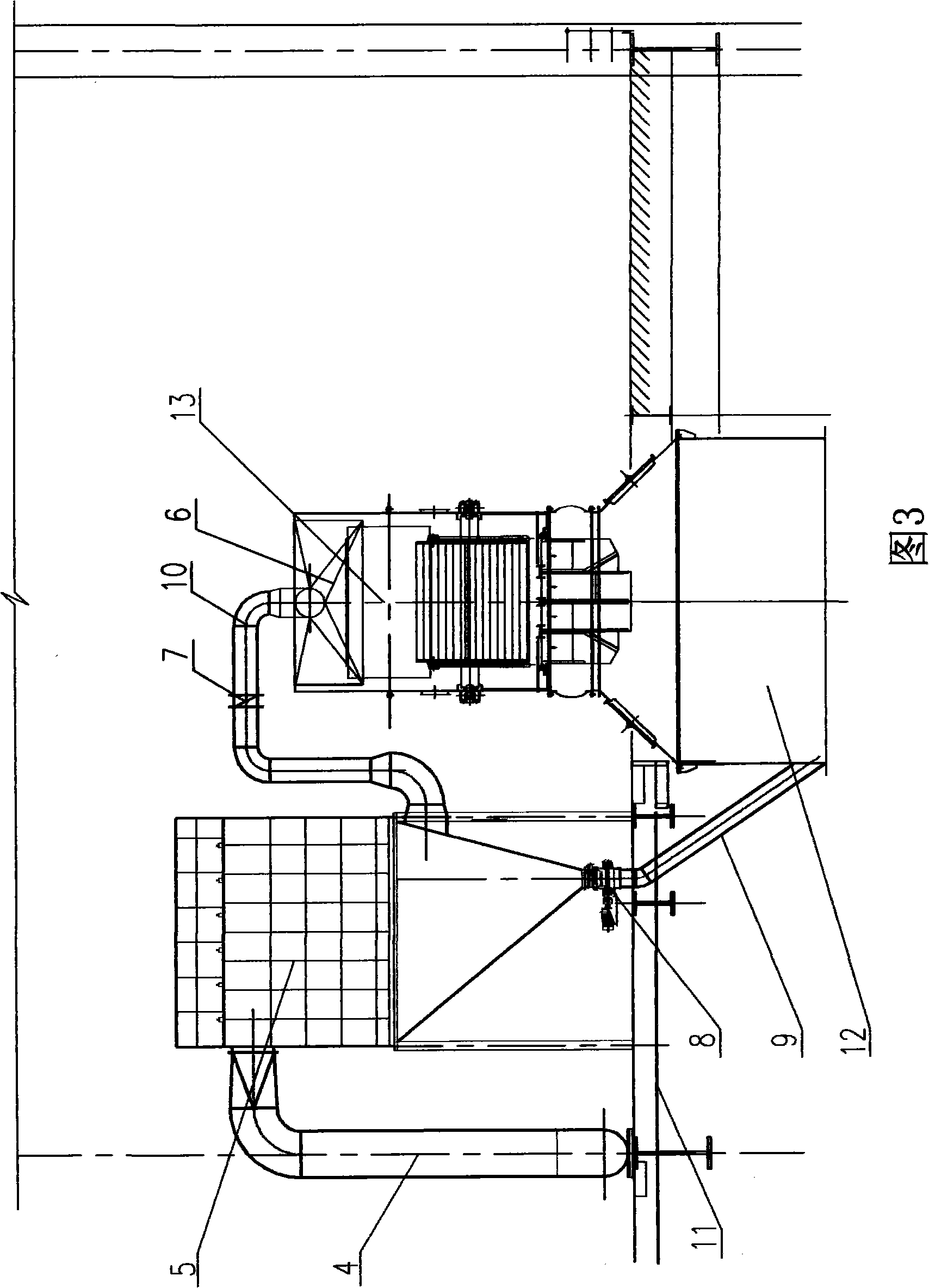

[0020] A blast furnace roof dedusting device, comprising a blower fan 1, a motor 2, a dust collector 5 and an airtight exhaust hood 6, the airtight exhaust hood 6 is arranged on the head of a belt conveyor 13, the blower fan 1 is driven by the motor 2, and The outlet of wind cover 6 is provided with first pipeline 10, and the other end of first pipeline 10 is connected with the inlet of dust collector 5, and above-mentioned fan 1, motor 2 and dust collector 5 are all arranged on blast furnace top platform 11, and dust collector 5 A second pipeline 4 is provided between the outlet of the dust collector 5 and the blower fan 1, a dust discharge valve 8 is provided at the outlet of the ash hopper of the dust collector 5, and a dust discharge pipe 9 is arranged on the dust discharge valve 8, and the dust discharge pipe The outlet of 9 communicates with the blast furnace charging tank 12 , an air volume regulating valve 7 is provided on the first pipeline 10 , and a vibration-damping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com