Distributed optical fibre oil gas conveying pipeline early early-warning system based on polarization detection

A distributed optical fiber and early warning technology, which is applied in the pipeline system, gas/liquid distribution and storage, and the use of optical devices to transmit sensing components, etc., can solve the problems of inability to warn criminals, short monitoring distance, troublesome sensor design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] The principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiment completed by the inventor according to the technical solution, and the present invention is not limited to this embodiment.

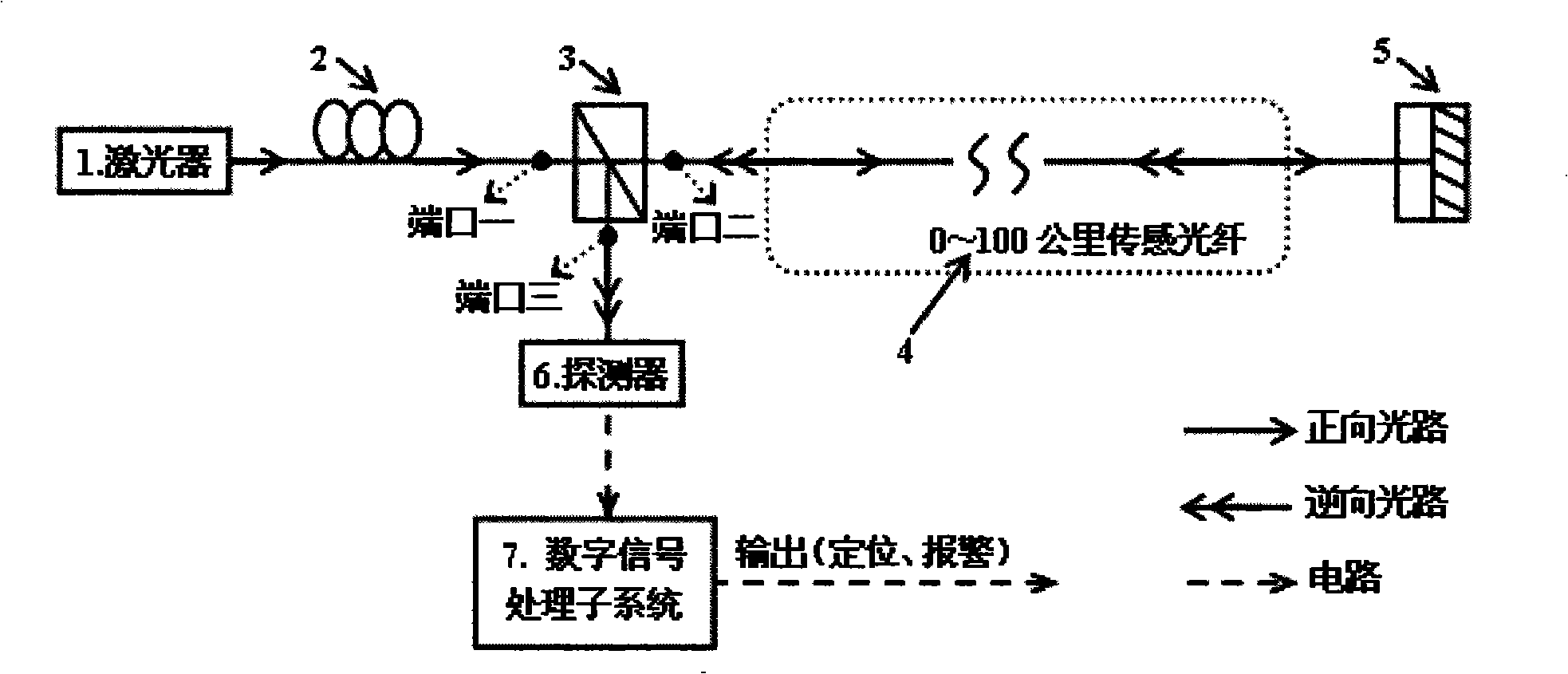

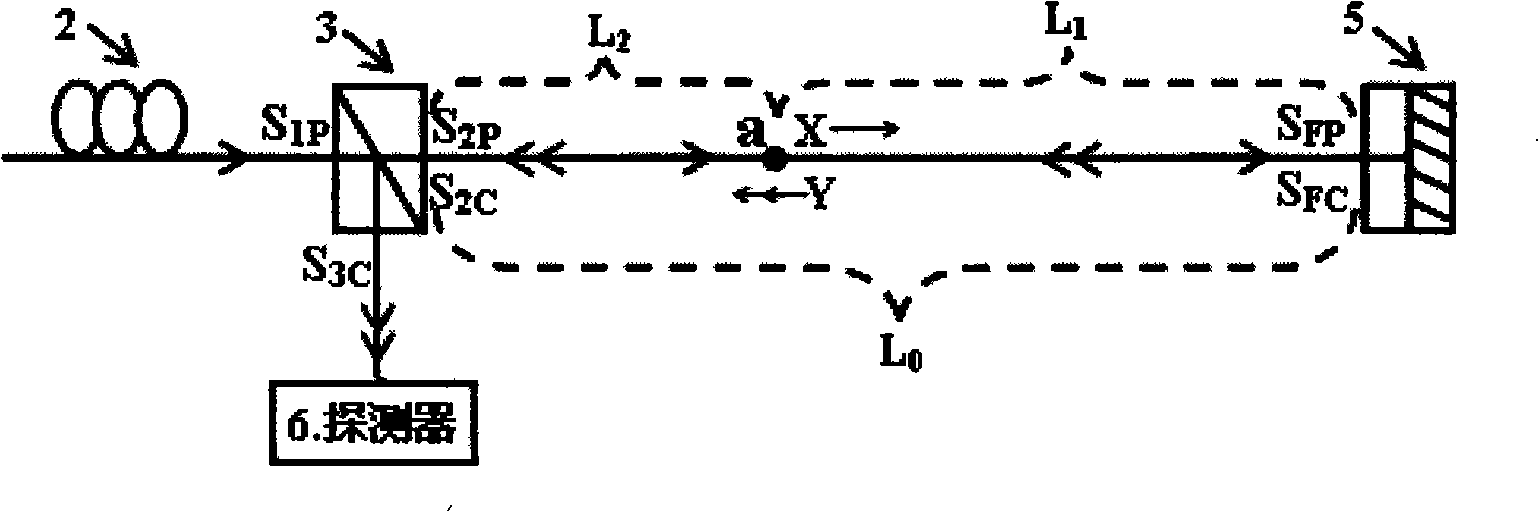

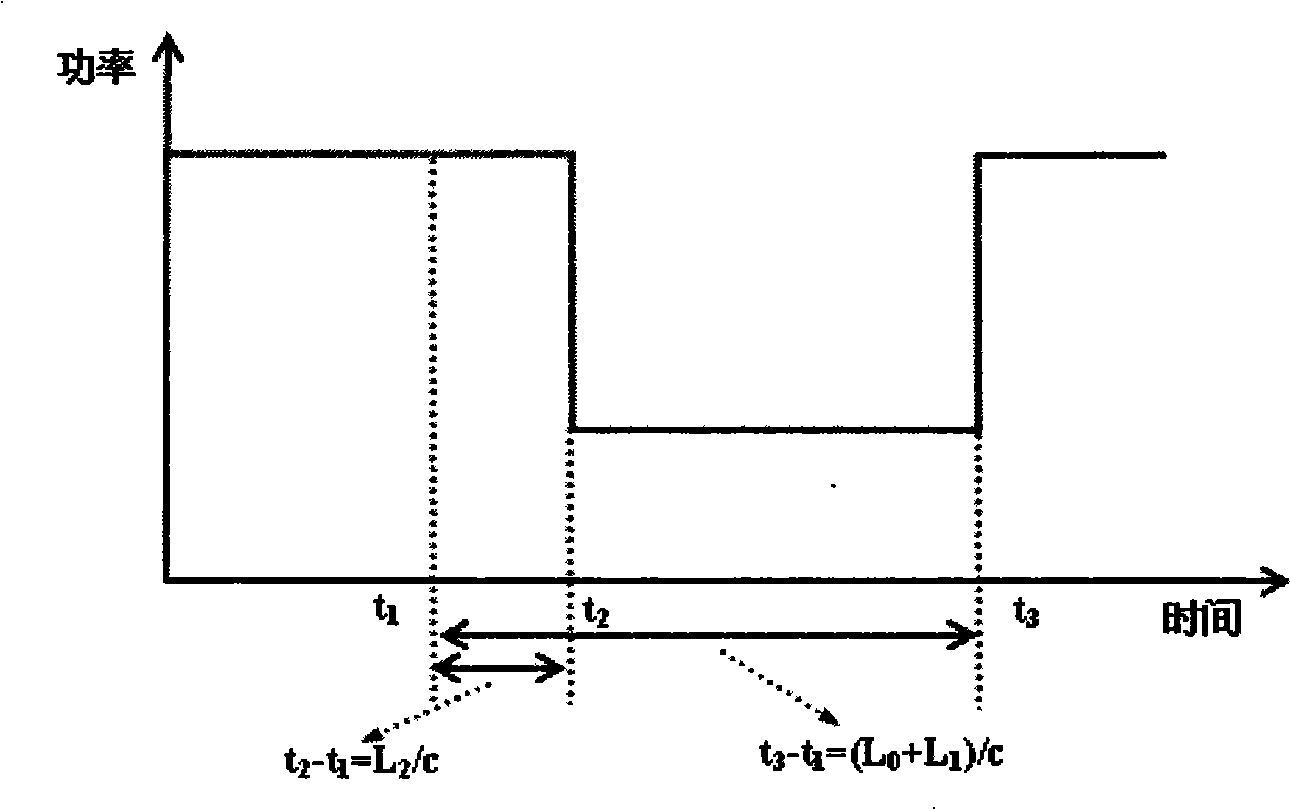

[0045] figure 1 It is a system block diagram of an embodiment of the present invention, wherein the definitions of forward light and reverse light polarization states of different ports of each device, and the working principle of the system are as follows figure 2 shown. First, explain the evolution process of the polarization state of each port when there is no disturbance in the sensing line:

[0046] Adjust the polarization controller so that: S → 1 P = S → 2 P (1)

[0047] Assume that w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com