Intelligent non-contact type minim biological reagent distribution method and its dispensing system

A non-contact, biological reagent technology, applied in precise distribution, a variety of reagents for intelligent, trace, rapid field, to achieve rapid fault real-time monitoring and diagnosis, less pollution, strong reagent viscosity adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

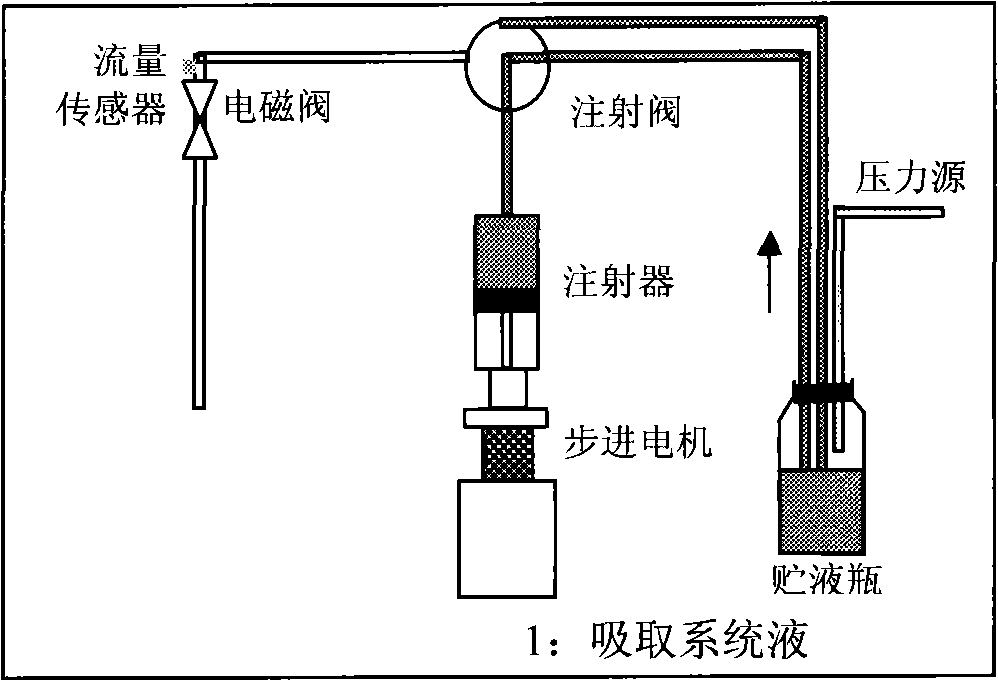

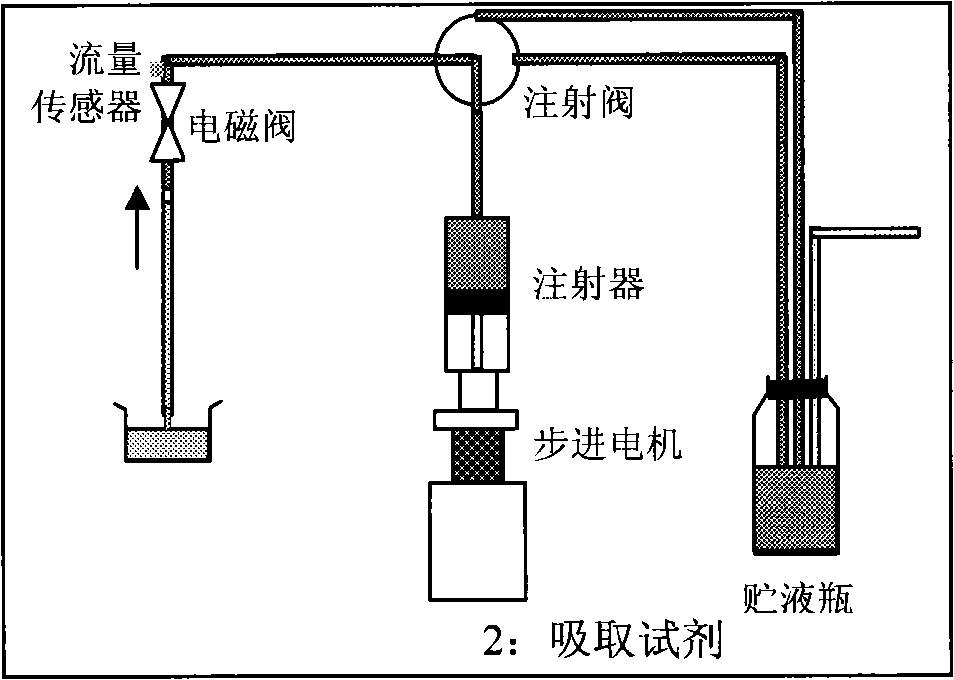

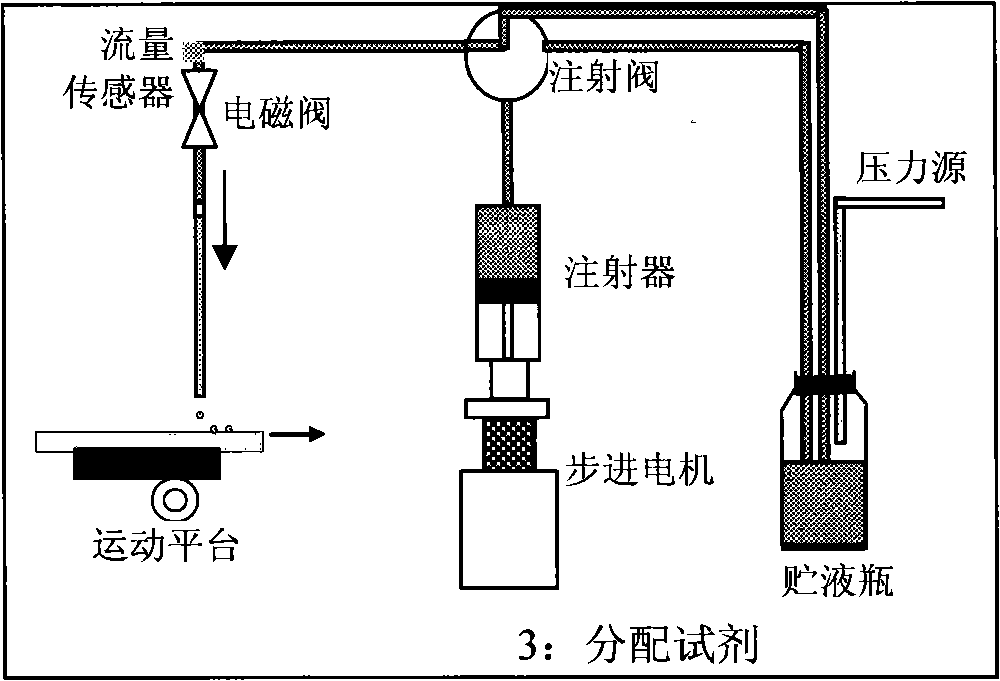

[0017] In this embodiment, a set of non-contact trace reagent dispensing method is developed by adopting the combination of pressure and electromagnetic valve. The dispensing system is mainly composed of injection pump, 4-2 injection valve, pressure storage reagent bottle, pressure adjustment system, solenoid valve, motion platform, sensor and intelligent operation control system and other parts. When the system is initially working, the injection valve is biased to the right, and the motor drives the syringe piston to move downward to draw the system liquid from the reagent bottle. Then the injection valve is biased to the left, and the motor drives the piston to move upward to fill the reagent into the pipeline system. Repeat several times to complete the cleaning and filling of the pipeline. When the reagent is sucked, the injection valve is turned to the left, the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com