Multi-shaft linkage series-parallel machine tool

A multi-axis linkage, machine tool technology, applied in metal processing mechanical parts, large fixed members, metal processing and other directions, can solve problems such as small workspace, complex CNC programming, and strong motion coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

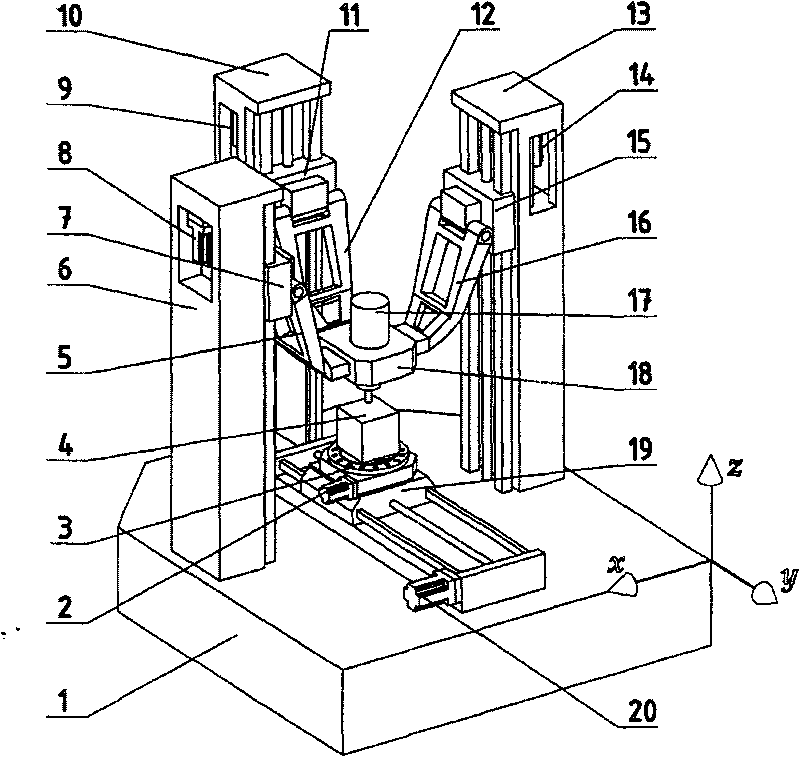

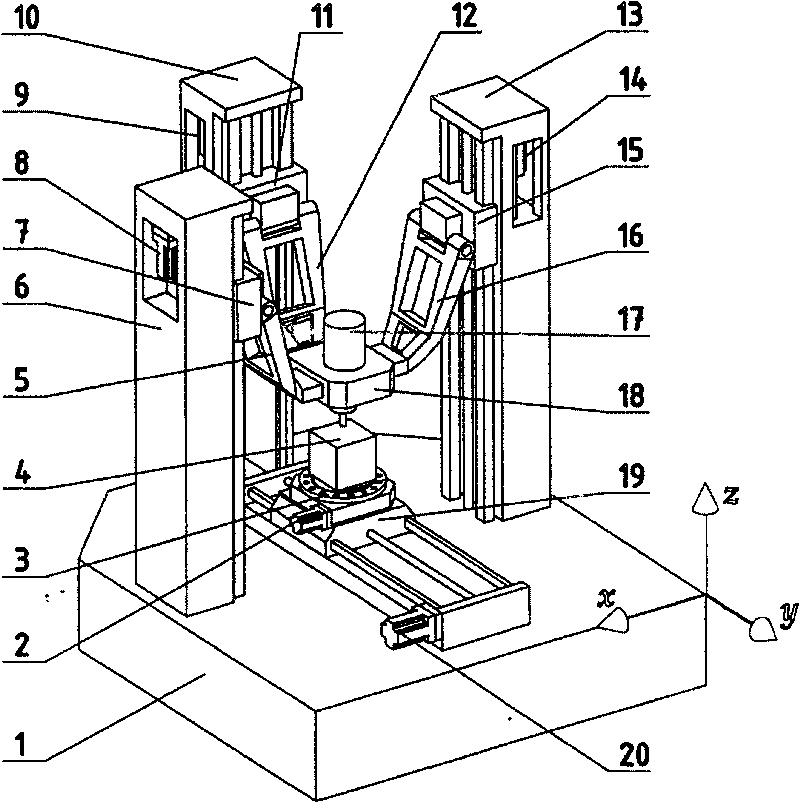

Embodiment 1

[0015] The structure of this embodiment 1, such as figure 1 As shown, it includes a bed 1, a movable platform 18 on which a spindle 17 is installed, a worktable on which a workpiece 4 is installed, and three uprights 6, 10, and 13 arranged on the bed. The three uprights are arranged in a triangular shape, and the upright guide rails are all arranged There are sliding saddles 7, 11, and 15 for linear motion. The three sliding saddles are respectively driven by ball screws by servo motors 8, 9, 14 installed in the columns; the machine tool is characterized in that the movable platform 18 The three branch chains 5, 12, and 16 are respectively connected with the saddles 7, 11, and 15 to form a spatial parallel closed chain mechanism. The spatial parallel closed chain mechanism can be used by the inventor in the application number 2007100623054.2, named "Sports The various structures disclosed in the “decoupled spatial three-degree-of-freedom parallel mechanism” patent application, t...

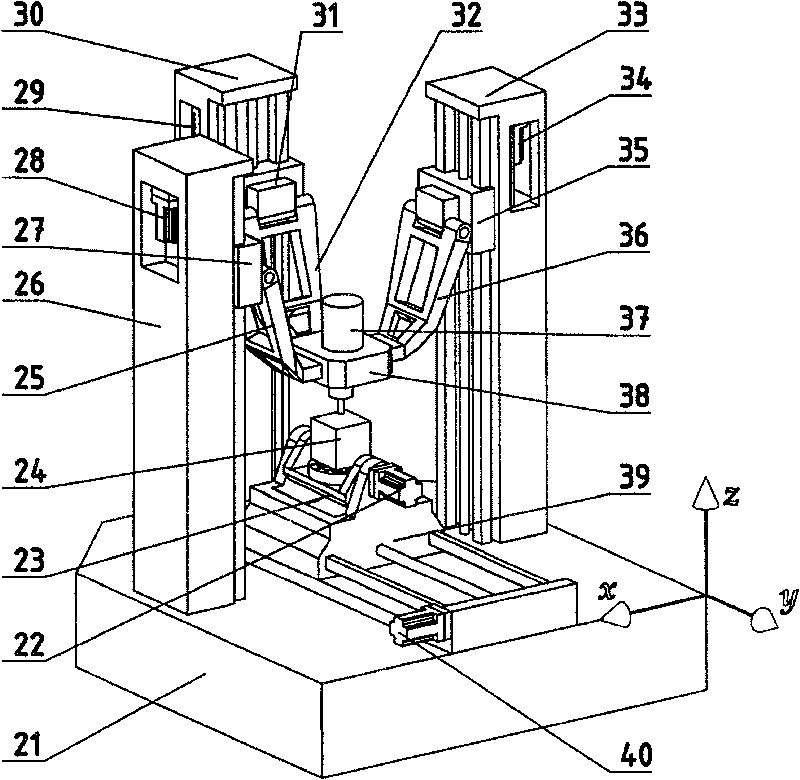

Embodiment 2

[0017] The structure of this embodiment 2, such as figure 2 As shown, the difference between the machine tool and Embodiment 1 is that the worktable is composed of a platform 23 that rotates around the y direction and a platform 39 that moves along the y direction. The platforms 23, 39 are driven by servo motors 22, 40, respectively. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com