Apparatus for separating gamma-terpinene paracymene with eucalyptus oil falling film type fractionating column

A technology of cymene and falling film type is applied in the field of fractionation towers for producing eucalyptus essential oil, which can solve the problems of increasing energy consumption, reducing aroma quality, and the difference in relative volatility being too small, so as to reduce costs and energy consumption. , Improve the relative volatility and ensure the effect of the first pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

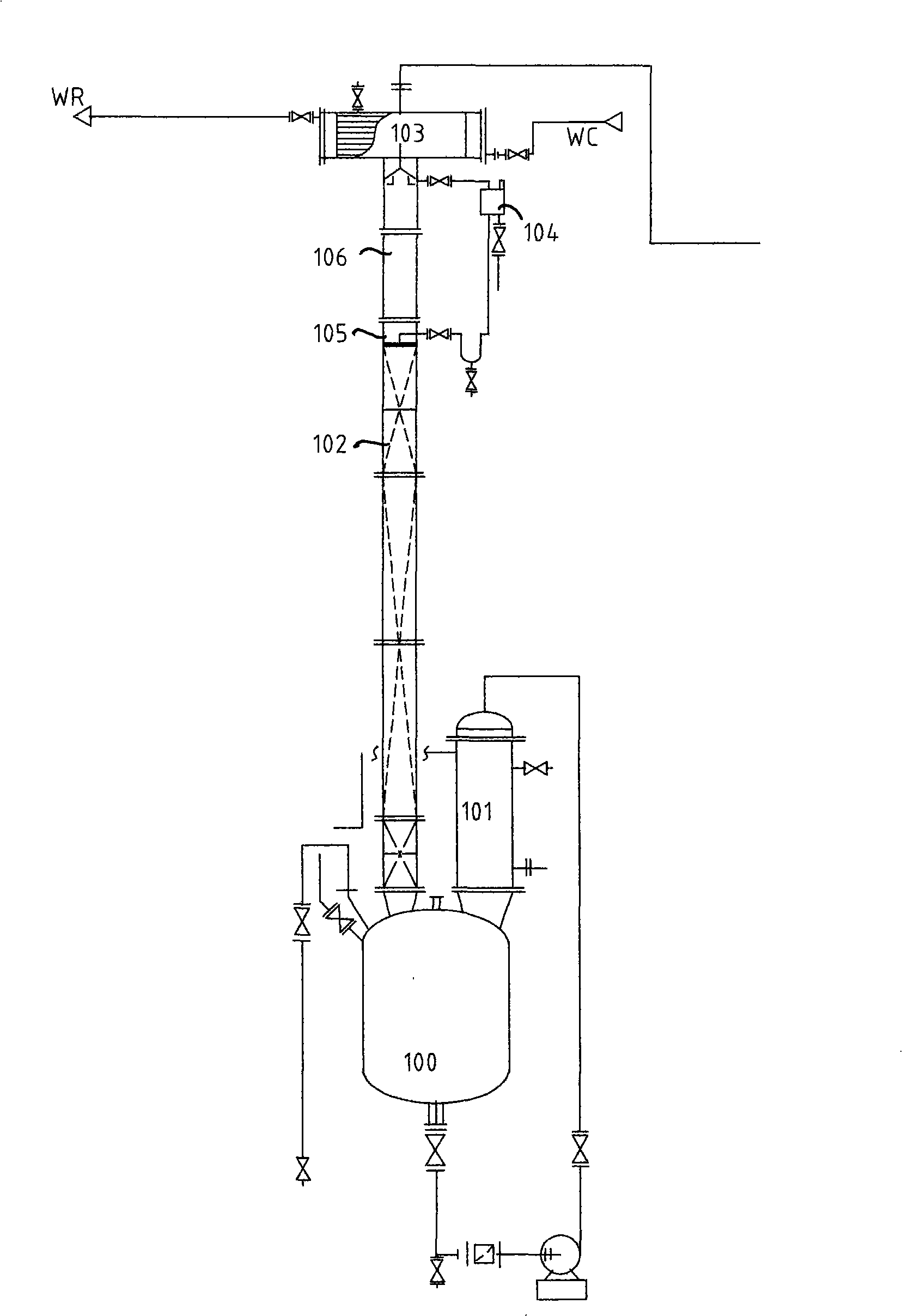

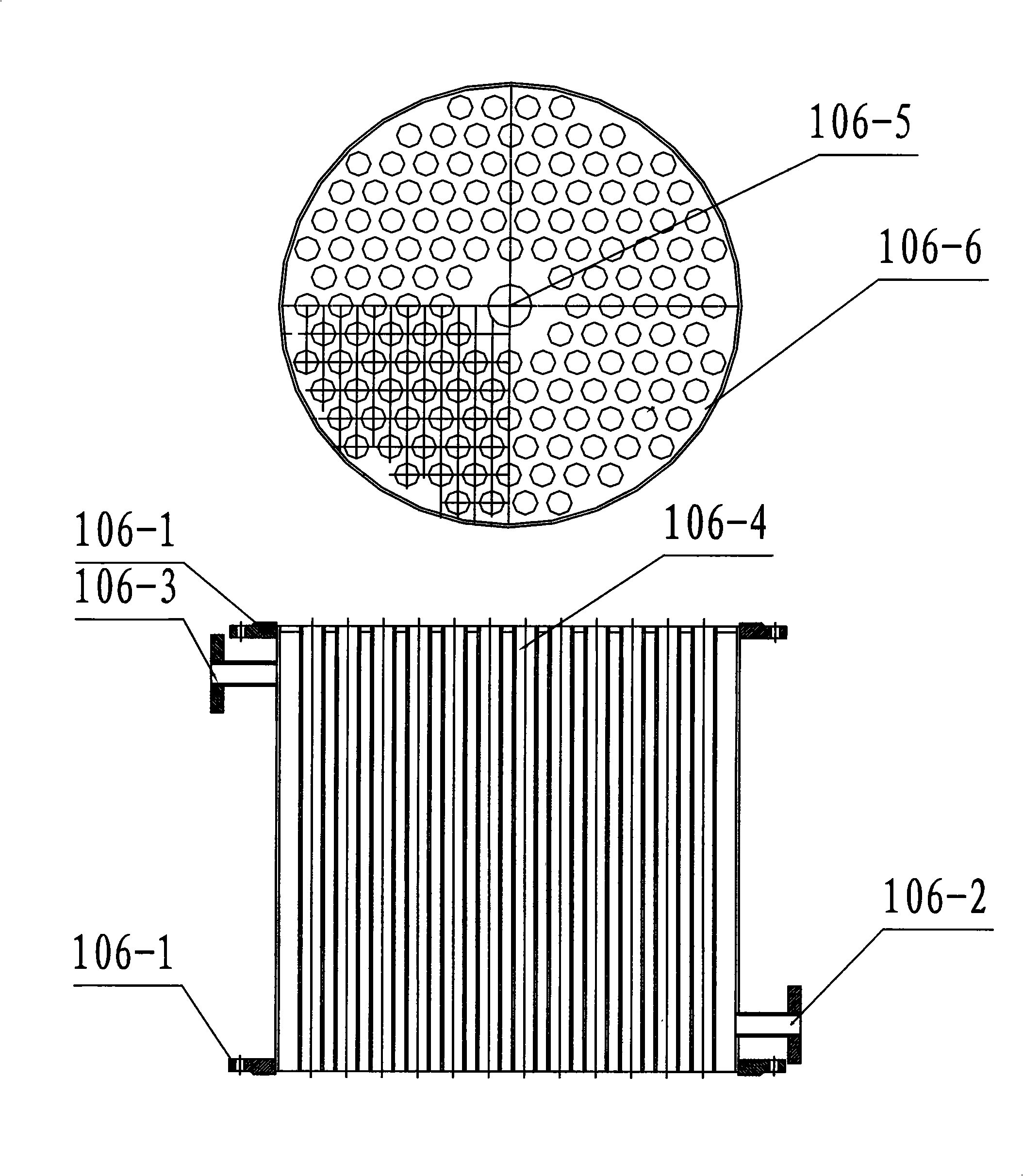

[0016] Between the original column and tube total condenser 103 and the reflux distributor 104 at the top of the tower, a condensation reflux channel 106 with a heat exchange area of 60-70% of the falling film heater 101 is fixed, that is, in the tower shell with a tower diameter of 600mm Install welded tube plate trays, put 150 32 tubes are fixed on the tube plate as the condensing channel tube bundle 106-4, the condensing channel tube bundle 106-4 is perpendicular to the vertical direction of the gas flow in the tower, and the arrangement of the tube bundle 106-4 on the tube plate is an equilateral triangle , and its piping area is 40% of the area of the tray 106-6. At the same time, the ratio of the length of the pipe to the diameter of the tower is 1:1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com