Galvano-chemistry preparation method for electrochromic magnesium-nickel alloy film

An alloy thin film and electrochromic technology, which is applied in the field of electrochemical preparation of electrochromic magnesium-nickel alloy thin films, can solve the problems of limiting the application of this thin film, high process conditions, and expensive equipment costs, and achieve low cost and simple operation , The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

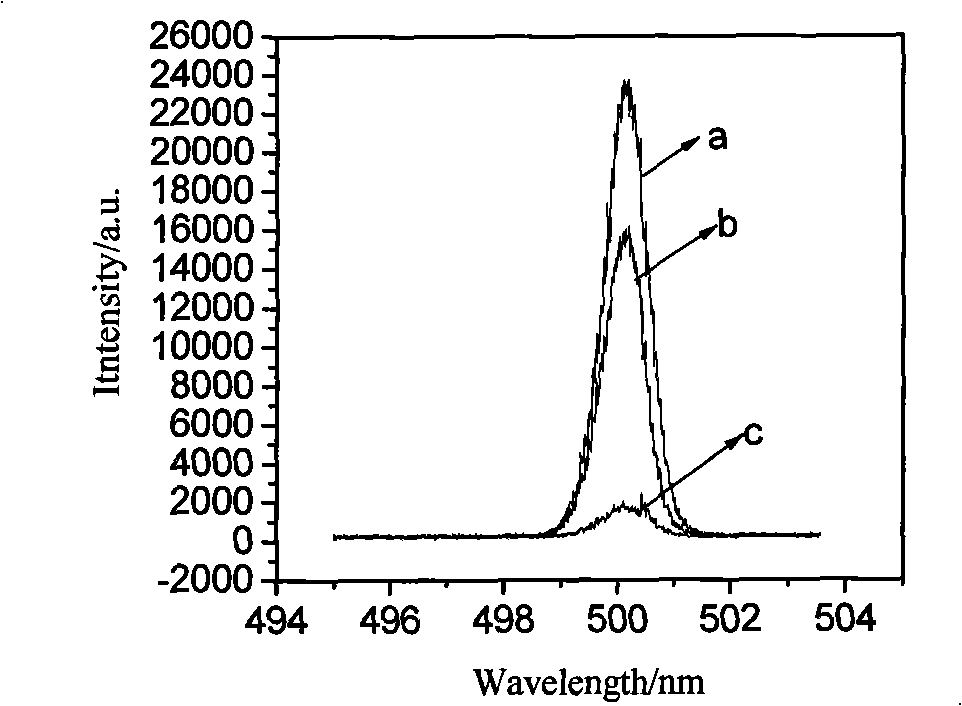

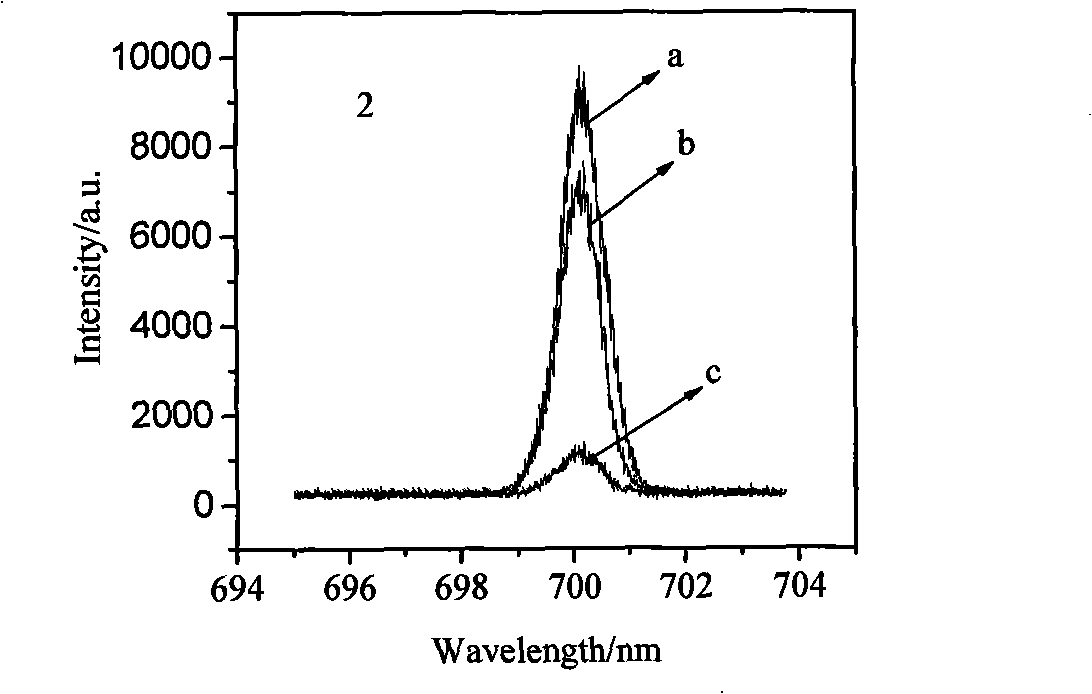

[0027] In the N, N-dimethylformamide solution with a magnesium perchlorate concentration of 0.2mol / L, a lithium perchlorate concentration of 0.2mol / L, and a nickel chloride concentration of 0.02mol / L, the control potential is -2.4 At V, the temperature was 20°C and 40°C respectively, and magnesium-nickel alloy thin films with good electrochromic properties could be obtained after electrification for 60 seconds.

Embodiment 2

[0029] In the N, N-dimethylformamide solution with a magnesium perchlorate concentration of 0.2mol / L, a lithium perchlorate concentration of 0.2mol / L, and a nickel chloride concentration of 0.02mol / L, the control potential is -2.8 At V, the temperature was 20°C and 40°C respectively, and magnesium-nickel alloy thin films with good electrochromic properties could be obtained after electrification for 50 seconds.

Embodiment 3

[0031] In the N, N-dimethylformamide solution with a magnesium perchlorate concentration of 0.2mol / L, a lithium perchlorate concentration of 0.2mol / L, and a nickel chloride concentration of 0.02mol / L, the control potential is -2.6 At V, the temperature is 30°C, and the power-on time is 120 seconds, 60 seconds, 30 seconds, and 20 seconds. It is confirmed by testing that alloy films with good discoloration properties can be obtained when electrodeposited for 30 seconds and 1 minute, and the alloy films with electrodeposited times of 120 seconds and 20 seconds have no obvious electrochromic performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com