Multifunctional integrated pulping equipment of high-concentration boiling and bleaching

A high-concentration steaming and multi-functional technology, which is used in digesters, pulp bleaching, textiles and papermaking, etc., can solve problems such as reducing production costs, and achieve the effect of solving high pollution and saving equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with example the present invention will be further described.

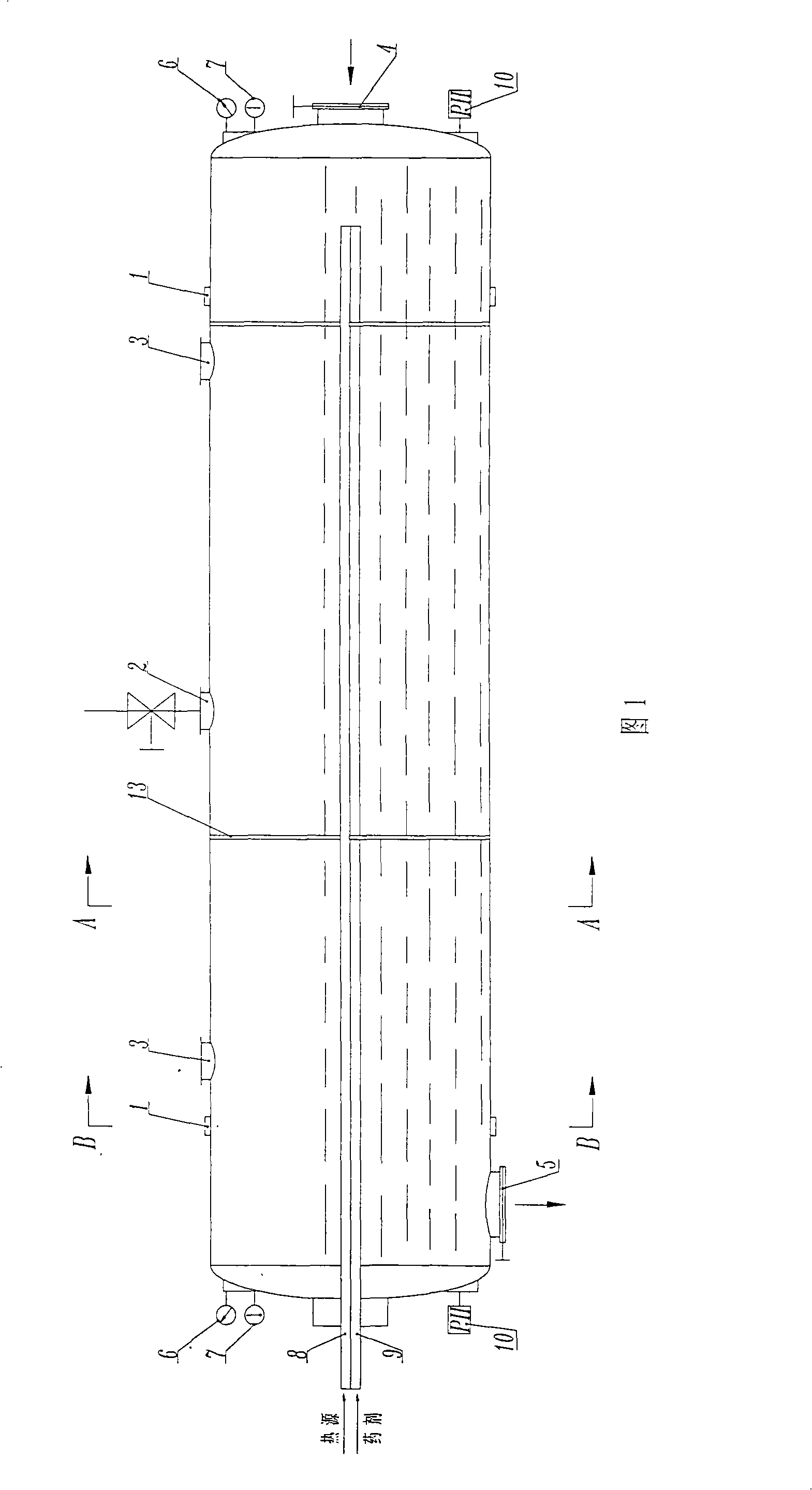

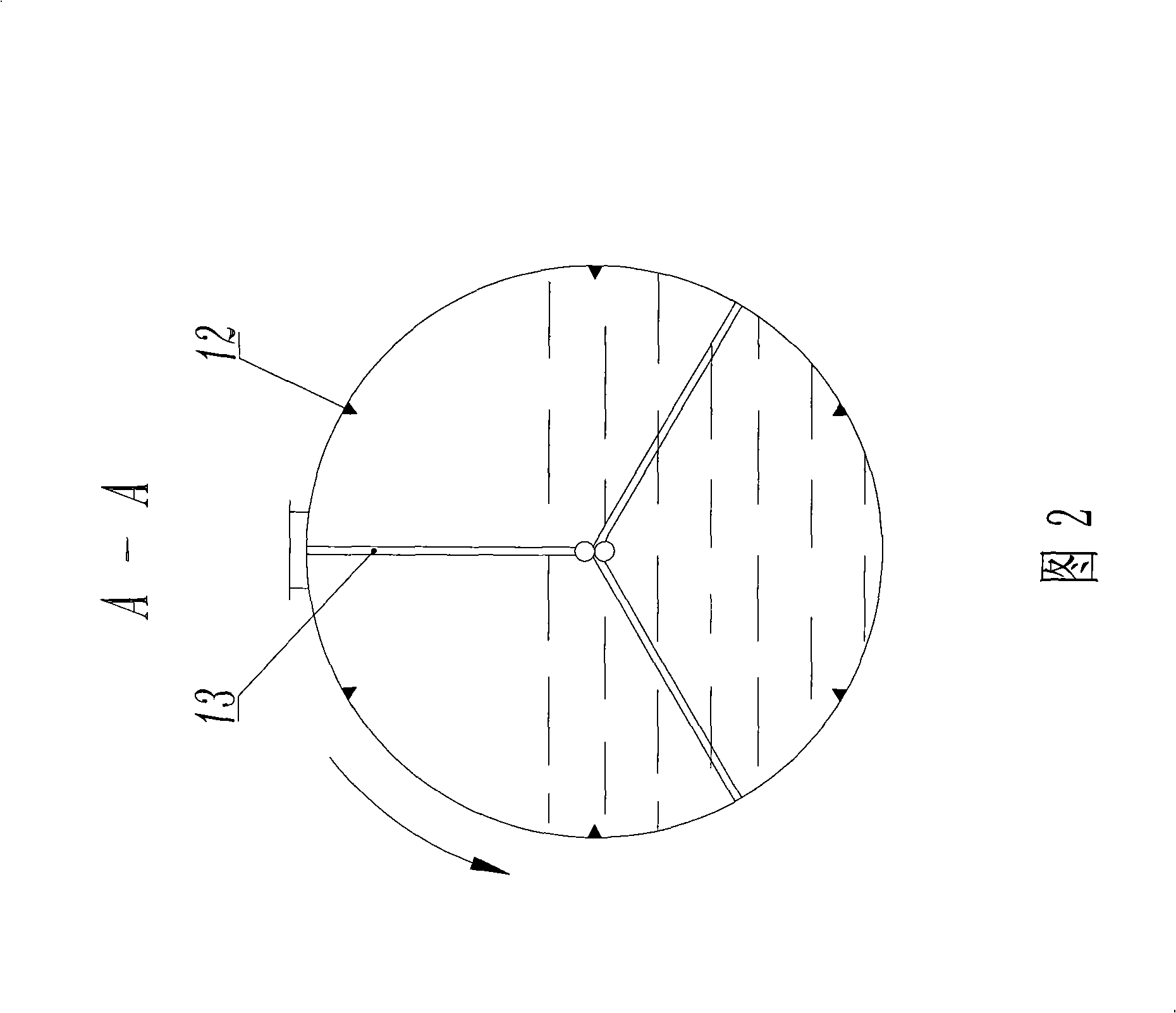

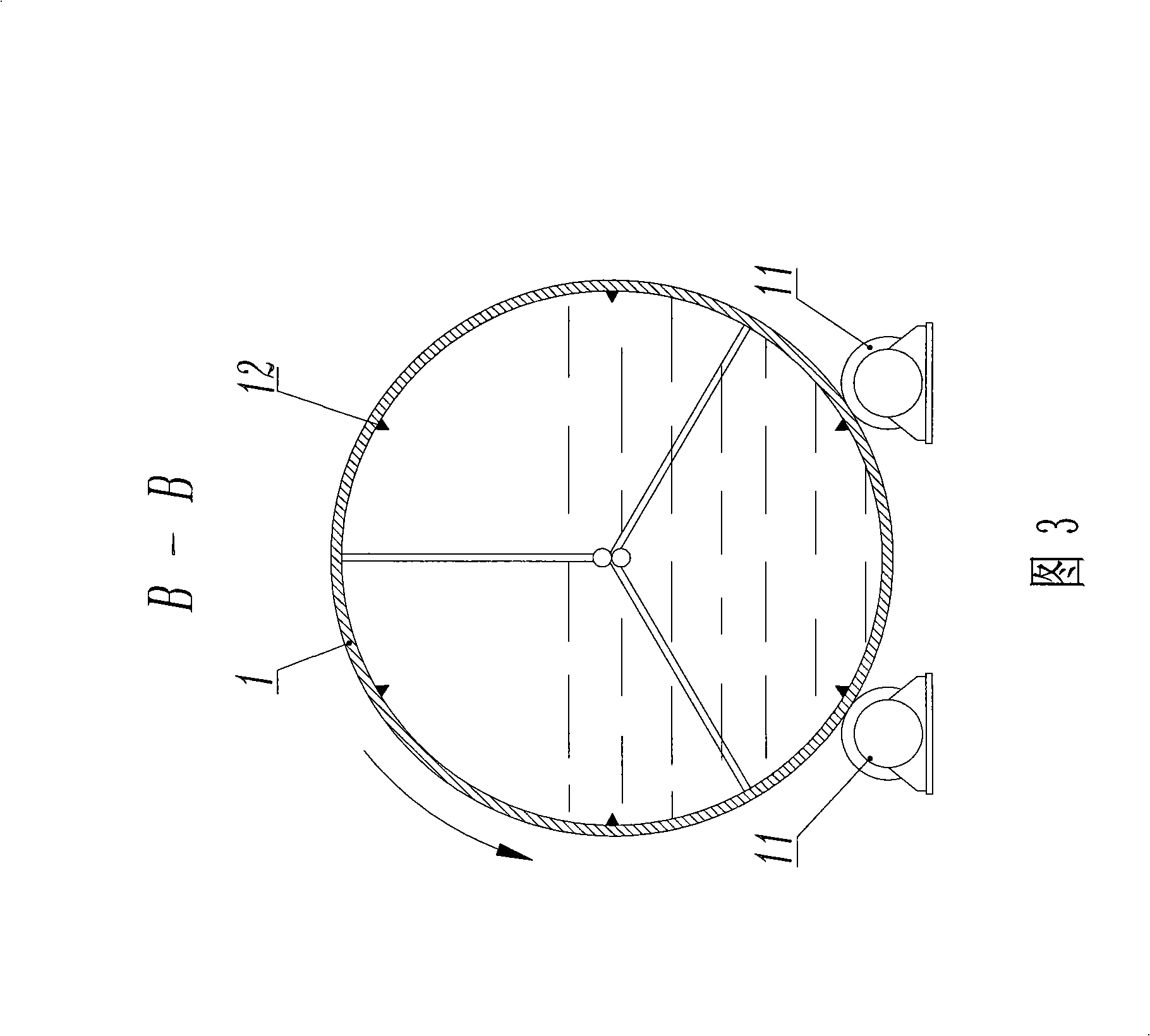

[0015] The pulping raw materials after material cutting, dust removal, purification and pretreatment are sent to the multi-functional high-consistency cooking and bleaching integrated pulping equipment through the conveying equipment, and enter through the feeding port 4, and the feeding port is equipped with a pressure-resistant valve. After the end, close the feeding valve, start the multi-functional high-consistency cooking and bleaching integrated pulping equipment, and then the equipment is driven by the power support driver 11 to rotate the rotating support ring 1; the heat source is fed through the heat source nozzle 8 to heat the raw material, and at the same time Medicament nozzle 9 is sent into presoaked medicament, and reaction starts. According to different types of raw materials, the pre-soaking time is slightly different. After pre-soaking for a certain period of time, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com