Advanced recovery and exhaustion system for reusable diesel exhaust gas

An exhaust system and diesel engine technology, applied in exhaust devices, mechanical equipment, engine components, etc., can solve the problems of large pressure fluctuation, low pulse energy utilization rate, complex exhaust pipe structure, etc. Competitive advantage, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

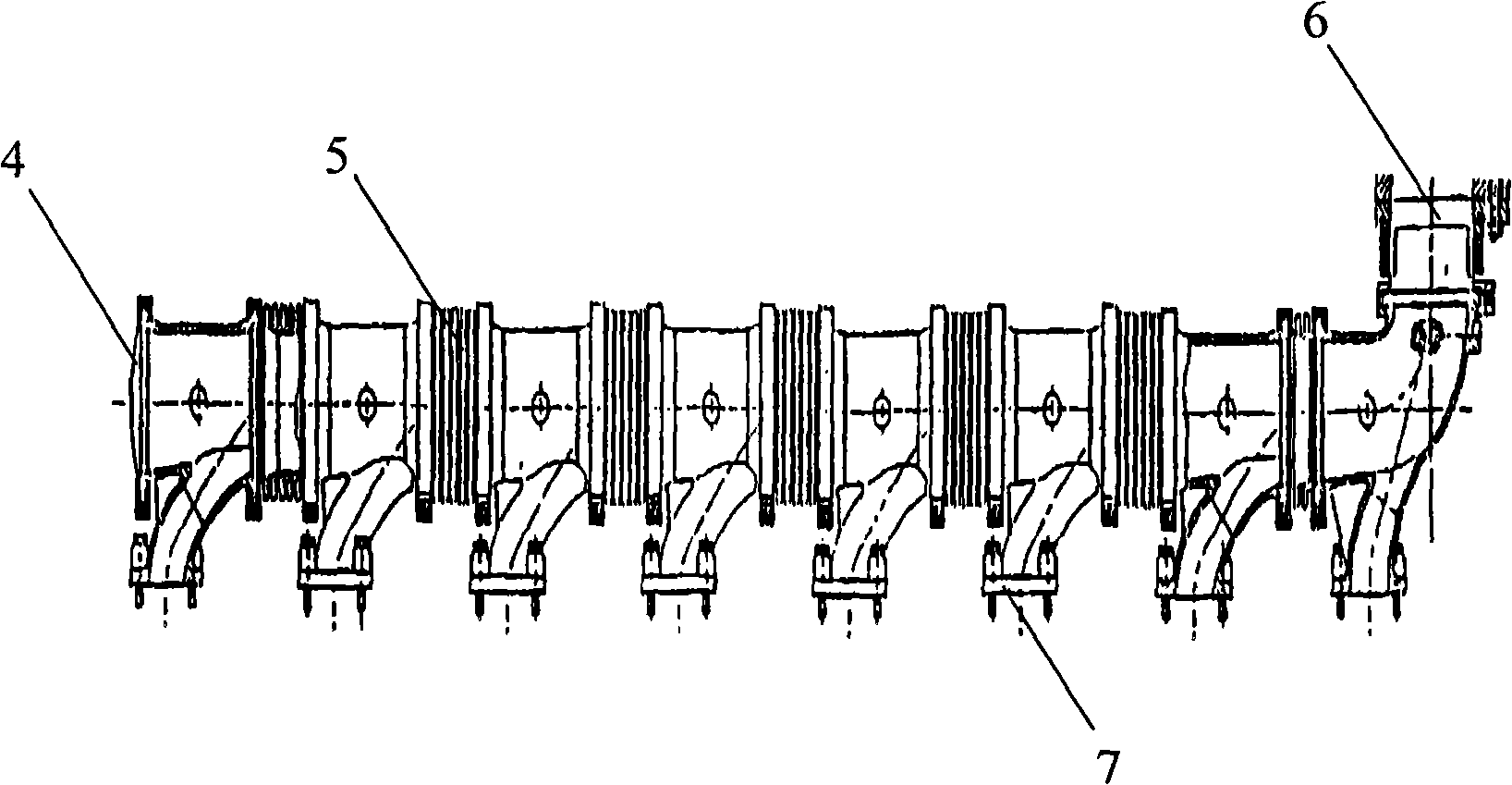

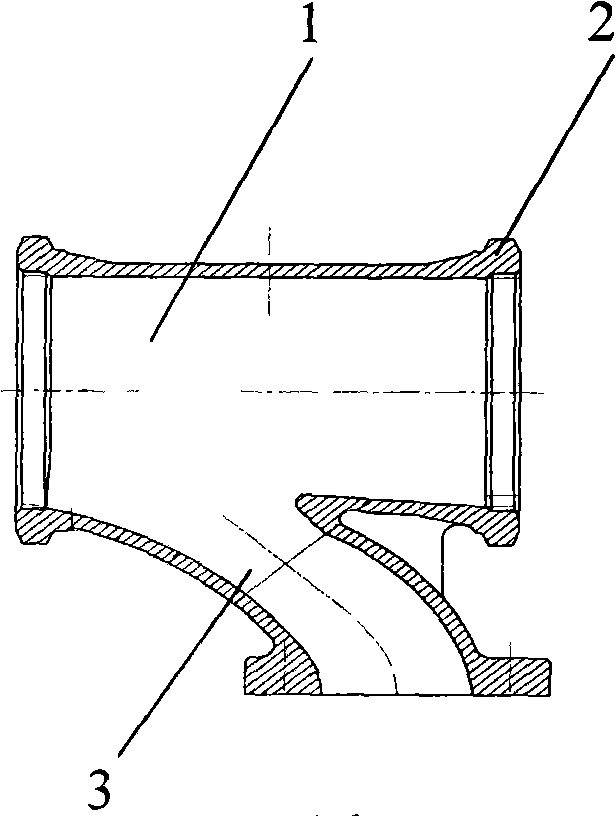

[0010] Such as figure 1 Shown: this embodiment is made of a plurality of exhaust pipe units and expansion joints, and each cylinder is connected with an exhaust pipe unit at its outlet. Each exhaust pipe unit includes a pipe body 1 and an exhaust branch pipe 3 (such as figure 2 As shown), the pipe body 1 is in the shape of a cylinder, and its two ends are provided with connecting flanges 2 for connecting the expansion joint 5; the exhaust branch pipe 3 is directly connected to the corresponding cylinder exhaust port through the flange 7. The pipe diameter of the exhaust branch pipe is tapered, like a shrinking nozzle, one end intersects the pipe body 1 at an angle, and the other end is connected to the cylinder exhaust port; the exhaust pipe unit of each adjacent cylinder is formed by an expansion joint 5 After being connected in series, the pipe body parts form the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com