Optical power equalizer for duplex laser scribing machine

A multi-channel laser and marking machine technology, applied in the field of optics, can solve problems such as increasing cost errors, and achieve the effects of improving quality, small errors, and ensuring consistent power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

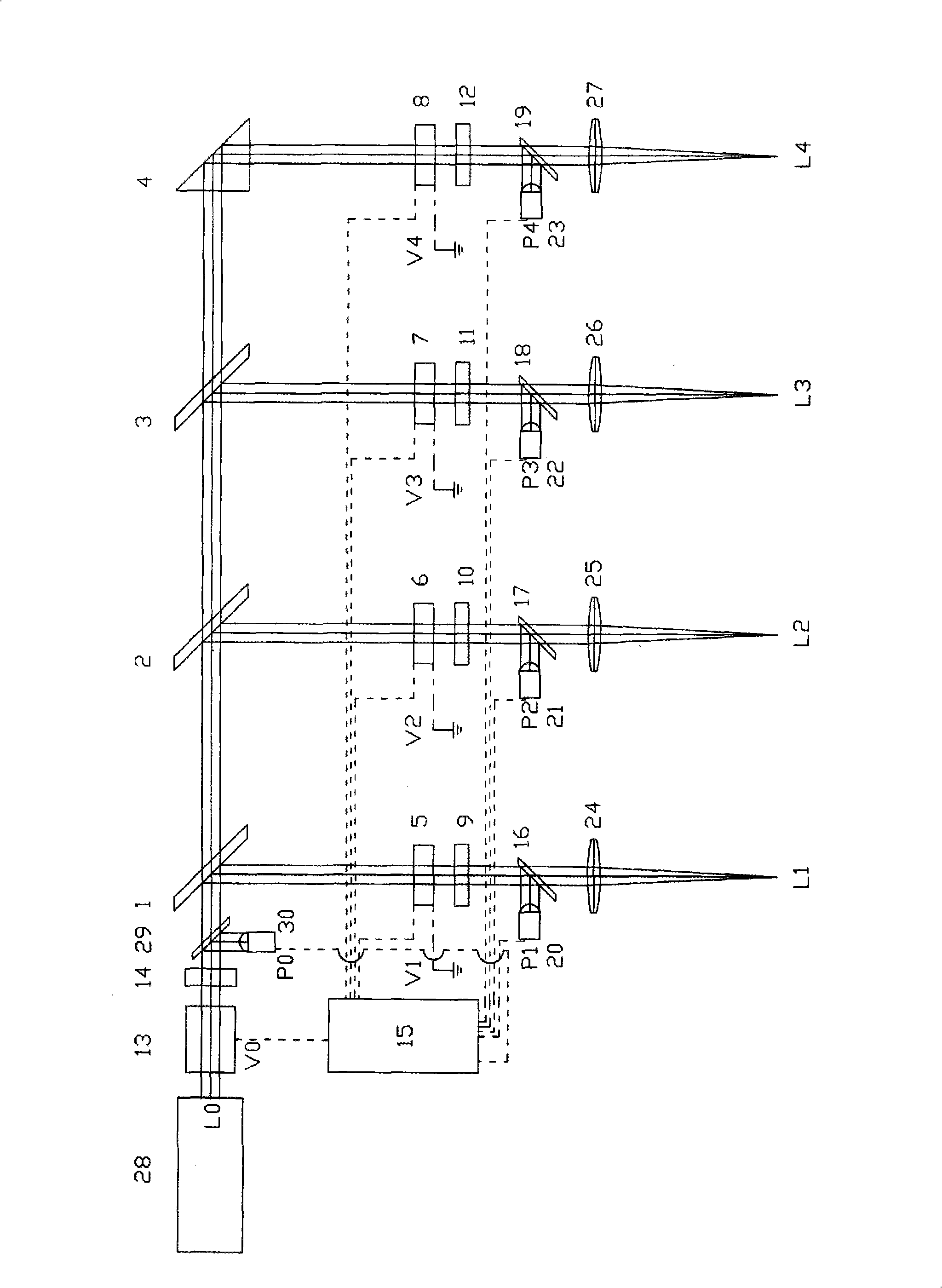

[0014] The implementation of the optical power equalizer used in the multi-channel laser marking machine provided by the present invention will be described below with reference to the accompanying drawings. FIG. 1 is a schematic diagram of the structure and optical path of a four-channel laser scriber equipped with an optical power equalizer for a multi-channel laser scriber provided by the present invention. At present, the general-purpose four-way laser marking machine is composed of a beam splitter 1 with a reflectivity of 1 / 4 when the laser is incident at 28 and 45°, a spectroscopic plate 2 with a reflectance of 1 / 3 when incident at 45°, and a reflectance at incident at 45° Be 1 / 2 dichroic sheet 3, total reflection prism 4, condenser lens 24,25,26,27 constitute. Its working process is: laser device 28 sends out a beam of laser light, successively passes through beam splitter 1,2,3 and total reflection prism 4 to form four bundles of downward parallel laser beams, then con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com